UV resistance plug purpose PVC compound

- Delivery Time:

- 5 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Jiangsu, China (Mainland) |

|---|

Product Description

Product Description

Specifications 1. Eco-friendly

2. Perfect flame-retardant performance

3. Good electric property

4. Easliy processed

5. Weatherability

♦ About Suzhou Mega Plastics Suzhou Mega was established in 2001, and betgan to develop environmentally conscious polymer compounds. Now, we are known as the lead manufacturer and supplier of PVC and LSHF compounds to producers around the world. Our customers come mainly from China, Taiwan, North America and Africa. Quality products with a commitment ot excellent customer service, Suzhou Mega manufactures more than 20,000 tons of compounds that comply with various global safety standards, such as the Rosh, UL and REACH, which are shipped to domestic and oversea markets alike. ♦ Product Application Apart from being used widely in the cable and wire industry, Mega's polymer compounds have a variety of applications, such as in the automotive, tool handle, toys, medical tubing and other industrial and residential applications. For each application, our engineers at Mega will customize and design particular formulation and process to meet each requirement of the compound, including hardness, color and cost. They will cooperate closely with customers to make sure that each specification of the compound is met. ♦ This Model MG-In-1: PVC compound for common power plug or connector MG-In-2: PVC compound for UV-resistance power plug or connector MG-In-3: PVC compound for Oil-resistance power plug or connector MG-In-4: PVC compound for ABS non-migration power plug or connector MG-In-5: PVC compound for ABS / PS non-migration power plug or connector INTRODUCTION Mega injection series are PVC resin based, mixed with inorganic flame-retardant agent, environmental-friendly plasticizers, highly effective stabilizers, fillers and processing aids. Our products meet the following requirements: REACH, ROHS, PAHS, POHS, and SONY 00259. There is absolutely no 6P (DEHP, DINP, DNOP, DIDP, DBP, BBP) nor heavy metals (lead, mercury, arsenic, chromium). Mega injection series have good insulation performance, weatherability, UV-resistance, thermal stability, solvent resistance, flame-retardance and low temperature flexibilty. Products of the injection series have been used widely in production of plugs and connectors. Technical Data Sheet

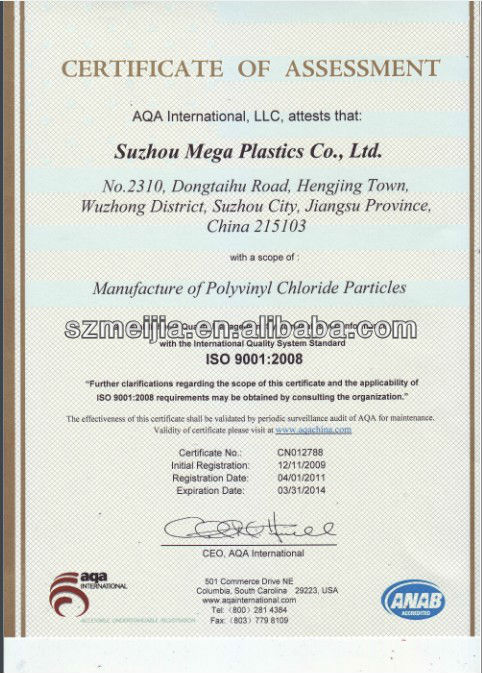

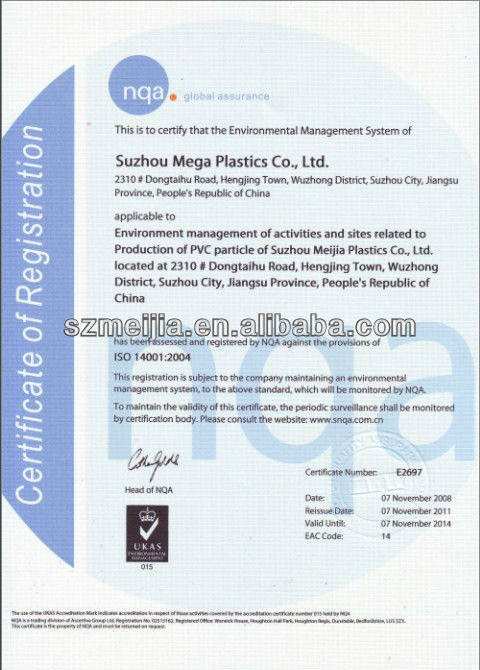

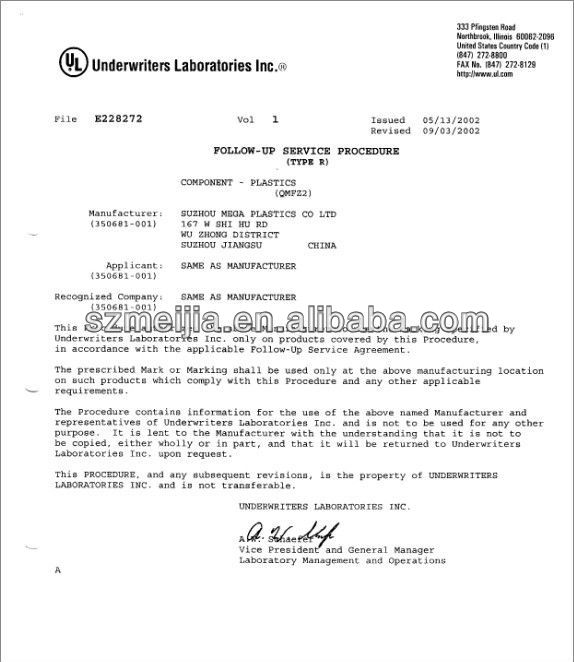

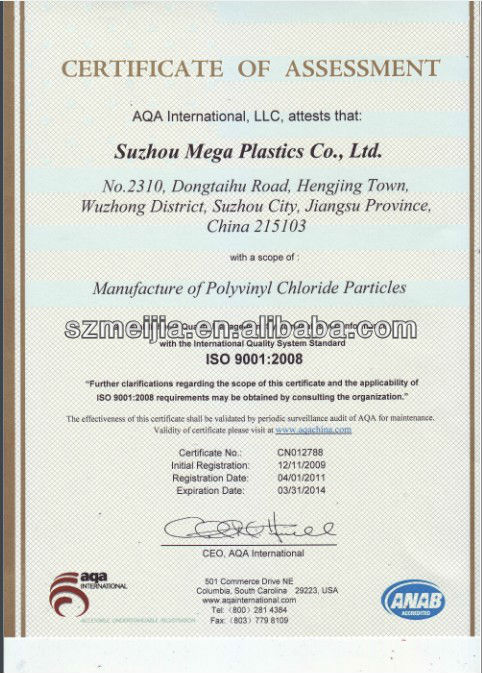

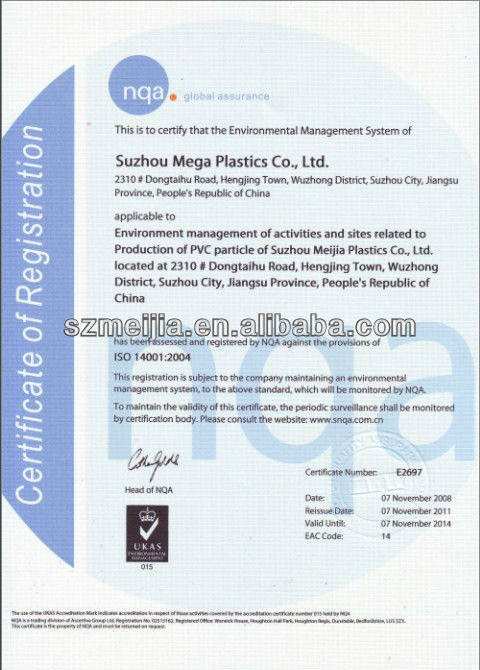

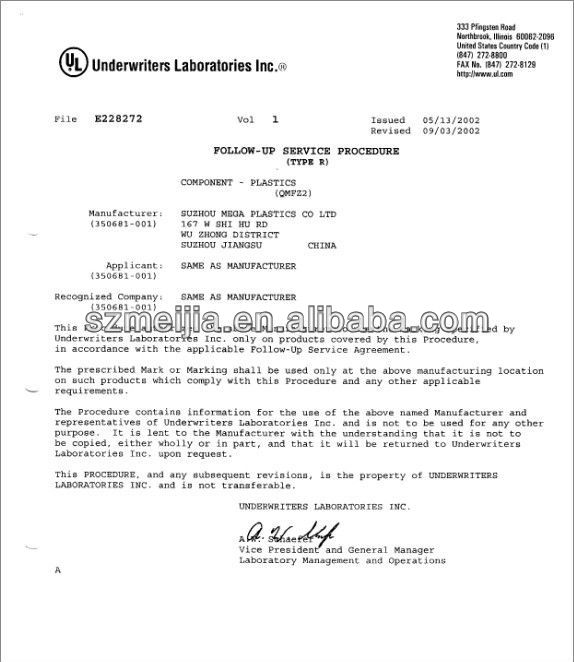

♦ Various Colours  ♦ Industry Listings and Certifications Product Safety: UL, CSA, VDE & CCC Quality Management System:ISO9001-2004 Environment Managemetn: ISO14001-2004 ♦ Well-furnished Office Space

♦ Industry Listings and Certifications Product Safety: UL, CSA, VDE & CCC Quality Management System:ISO9001-2004 Environment Managemetn: ISO14001-2004 ♦ Well-furnished Office Space  ♦ Advanced Laboratory With highly-skilled staff and well-equipped laboratory, Suzhou Mega triple tests each of the compound that it produces to ensure the products consistently meet ech customer's requirements. We are now able to perform the following testing procedures: 1) tensile strength, 2) elongation, 3) gravity, 4) air oven aging, 5) color meter, 6) water resistance, 7) oil resistance. Additionally, Mega also uses atomic abosroption spectrometry (Aa) and X-Ray spectrometry to analyze environmental sensitive elements of raw materials, so as to ensure that the products comploy withRoSH standards.

♦ Advanced Laboratory With highly-skilled staff and well-equipped laboratory, Suzhou Mega triple tests each of the compound that it produces to ensure the products consistently meet ech customer's requirements. We are now able to perform the following testing procedures: 1) tensile strength, 2) elongation, 3) gravity, 4) air oven aging, 5) color meter, 6) water resistance, 7) oil resistance. Additionally, Mega also uses atomic abosroption spectrometry (Aa) and X-Ray spectrometry to analyze environmental sensitive elements of raw materials, so as to ensure that the products comploy withRoSH standards.

♦ International Certification & Recognition Product Safety: UL, CSA, VDE & CCC Quality Management System:ISO9001-2004 Environment Managemetn: ISO14001-2004

♦ International Certification & Recognition Product Safety: UL, CSA, VDE & CCC Quality Management System:ISO9001-2004 Environment Managemetn: ISO14001-2004

♦ Green & Environmental Mega is extremely conscious of the environment, and is therefore committed to provide customers with accurate information about our products and production processes. We ensure that these processes align with and exceed industry standards. We are proud to work cooperatively iwth each of our customers to address their product and market needs. We are committed to continue to find new ways to formulate new and existing products that will have minimal hazardous ingredients and effects on the environment. Our green compliance system will continue to be Mega's core competitive advantage as the market shifts and desire better and higher quality products, while causing minimal harm to the environment. ♦ Contact Information If you would like to have more information about our products or are interested in establishing business relationship with us, feel free to reach us at: Tel: 86-512-65275752 Fax: 86-512-65277403 Phone: 86-13404235070 Website: www.megaplastics.com If possible, please include the following information in your inquiry. Density Color Shore Hardness Mechanical Properties Electrical Properties Flame-retardant Grade Others We look forward to hearing back from you! :)

♦ Green & Environmental Mega is extremely conscious of the environment, and is therefore committed to provide customers with accurate information about our products and production processes. We ensure that these processes align with and exceed industry standards. We are proud to work cooperatively iwth each of our customers to address their product and market needs. We are committed to continue to find new ways to formulate new and existing products that will have minimal hazardous ingredients and effects on the environment. Our green compliance system will continue to be Mega's core competitive advantage as the market shifts and desire better and higher quality products, while causing minimal harm to the environment. ♦ Contact Information If you would like to have more information about our products or are interested in establishing business relationship with us, feel free to reach us at: Tel: 86-512-65275752 Fax: 86-512-65277403 Phone: 86-13404235070 Website: www.megaplastics.com If possible, please include the following information in your inquiry. Density Color Shore Hardness Mechanical Properties Electrical Properties Flame-retardant Grade Others We look forward to hearing back from you! :)

2. Perfect flame-retardant performance

3. Good electric property

4. Easliy processed

5. Weatherability

♦ About Suzhou Mega Plastics Suzhou Mega was established in 2001, and betgan to develop environmentally conscious polymer compounds. Now, we are known as the lead manufacturer and supplier of PVC and LSHF compounds to producers around the world. Our customers come mainly from China, Taiwan, North America and Africa. Quality products with a commitment ot excellent customer service, Suzhou Mega manufactures more than 20,000 tons of compounds that comply with various global safety standards, such as the Rosh, UL and REACH, which are shipped to domestic and oversea markets alike. ♦ Product Application Apart from being used widely in the cable and wire industry, Mega's polymer compounds have a variety of applications, such as in the automotive, tool handle, toys, medical tubing and other industrial and residential applications. For each application, our engineers at Mega will customize and design particular formulation and process to meet each requirement of the compound, including hardness, color and cost. They will cooperate closely with customers to make sure that each specification of the compound is met. ♦ This Model MG-In-1: PVC compound for common power plug or connector MG-In-2: PVC compound for UV-resistance power plug or connector MG-In-3: PVC compound for Oil-resistance power plug or connector MG-In-4: PVC compound for ABS non-migration power plug or connector MG-In-5: PVC compound for ABS / PS non-migration power plug or connector INTRODUCTION Mega injection series are PVC resin based, mixed with inorganic flame-retardant agent, environmental-friendly plasticizers, highly effective stabilizers, fillers and processing aids. Our products meet the following requirements: REACH, ROHS, PAHS, POHS, and SONY 00259. There is absolutely no 6P (DEHP, DINP, DNOP, DIDP, DBP, BBP) nor heavy metals (lead, mercury, arsenic, chromium). Mega injection series have good insulation performance, weatherability, UV-resistance, thermal stability, solvent resistance, flame-retardance and low temperature flexibilty. Products of the injection series have been used widely in production of plugs and connectors. Technical Data Sheet

Test Items | Unit | Typical Value | ||||

In-1 | In-2 | In-3 | In-4 | In-5 | ||

Density (23°C) | g/cm3 | 1.40±0.05 | 1.40±0.05 | 1.40±0.05 | 1.40±0.05 | 1.40±0.05 |

Hardness (Shore A) | A | 55-100 A | 55-100 A | 55-100 A | 55-100 A | 55-100 A |

Tensile strength | MPa | ≥12 | ≥12 | ≥12 | ≥12 | ≥12 |

Elongation at break | % | ≥150 | ≥150 | ≥150 | ≥150 | ≥150 |

Minimum percent of unaged value |

|

|

|

| ||

Tensile strength, percent | % | 75 | 75 | 75 | 75 | 75 |

Elongation, percent | % | 65 | 65 | 65 | 65 | 65 |

Low temperature brittleness | °C | -15 | -15 | -15 | -15 | -15 |

20°C Volume resistivity | Ω·m | 1.0x108 | 1.0x108 | 1.0x108 | 1.0x108 | 1.0x108 |

Dielectric strength | MV/m | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 |

| Flame-retardant (UL 94) | - | OK | OK | OK | OK | OK |

♦ Industry Listings and Certifications Product Safety: UL, CSA, VDE & CCC Quality Management System:ISO9001-2004 Environment Managemetn: ISO14001-2004 ♦ Well-furnished Office Space

♦ Industry Listings and Certifications Product Safety: UL, CSA, VDE & CCC Quality Management System:ISO9001-2004 Environment Managemetn: ISO14001-2004 ♦ Well-furnished Office Space  ♦ Advanced Laboratory With highly-skilled staff and well-equipped laboratory, Suzhou Mega triple tests each of the compound that it produces to ensure the products consistently meet ech customer's requirements. We are now able to perform the following testing procedures: 1) tensile strength, 2) elongation, 3) gravity, 4) air oven aging, 5) color meter, 6) water resistance, 7) oil resistance. Additionally, Mega also uses atomic abosroption spectrometry (Aa) and X-Ray spectrometry to analyze environmental sensitive elements of raw materials, so as to ensure that the products comploy withRoSH standards.

♦ Advanced Laboratory With highly-skilled staff and well-equipped laboratory, Suzhou Mega triple tests each of the compound that it produces to ensure the products consistently meet ech customer's requirements. We are now able to perform the following testing procedures: 1) tensile strength, 2) elongation, 3) gravity, 4) air oven aging, 5) color meter, 6) water resistance, 7) oil resistance. Additionally, Mega also uses atomic abosroption spectrometry (Aa) and X-Ray spectrometry to analyze environmental sensitive elements of raw materials, so as to ensure that the products comploy withRoSH standards.

♦ International Certification & Recognition Product Safety: UL, CSA, VDE & CCC Quality Management System:ISO9001-2004 Environment Managemetn: ISO14001-2004

♦ International Certification & Recognition Product Safety: UL, CSA, VDE & CCC Quality Management System:ISO9001-2004 Environment Managemetn: ISO14001-2004

♦ Green & Environmental Mega is extremely conscious of the environment, and is therefore committed to provide customers with accurate information about our products and production processes. We ensure that these processes align with and exceed industry standards. We are proud to work cooperatively iwth each of our customers to address their product and market needs. We are committed to continue to find new ways to formulate new and existing products that will have minimal hazardous ingredients and effects on the environment. Our green compliance system will continue to be Mega's core competitive advantage as the market shifts and desire better and higher quality products, while causing minimal harm to the environment. ♦ Contact Information If you would like to have more information about our products or are interested in establishing business relationship with us, feel free to reach us at: Tel: 86-512-65275752 Fax: 86-512-65277403 Phone: 86-13404235070 Website: www.megaplastics.com If possible, please include the following information in your inquiry. Density Color Shore Hardness Mechanical Properties Electrical Properties Flame-retardant Grade Others We look forward to hearing back from you! :)

♦ Green & Environmental Mega is extremely conscious of the environment, and is therefore committed to provide customers with accurate information about our products and production processes. We ensure that these processes align with and exceed industry standards. We are proud to work cooperatively iwth each of our customers to address their product and market needs. We are committed to continue to find new ways to formulate new and existing products that will have minimal hazardous ingredients and effects on the environment. Our green compliance system will continue to be Mega's core competitive advantage as the market shifts and desire better and higher quality products, while causing minimal harm to the environment. ♦ Contact Information If you would like to have more information about our products or are interested in establishing business relationship with us, feel free to reach us at: Tel: 86-512-65275752 Fax: 86-512-65277403 Phone: 86-13404235070 Website: www.megaplastics.com If possible, please include the following information in your inquiry. Density Color Shore Hardness Mechanical Properties Electrical Properties Flame-retardant Grade Others We look forward to hearing back from you! :) Related Keywords

Related Keywords