Semi rigid sealing strips for window/door of PVC

- Delivery Time:

- 7 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Jiangsu, China (Mainland) |

|---|

Product Description

Product Description

Specifications 1. Weatherability

2. UV resistance

3. Flame-retardant

4. Environmental friendly

5. Low temperature properties

GL 1 Sealing strips for glass of low-rise and mid-rise building GL 2 Sealing strips for glass of high-rise and cold area We 1 Sealing strips for window profile of low-rise and mid-rise building We 2 Sealing strips for window profile of high-rise and cold area

Mega sealing strips series can be used in window and door profile, auto and so on. Our products meet the requirements of REACH, ROHS, PAHS, POHS, SONY 00259 etc. We can promise there are no heavy metals such as lead, barium, mercury, cadmium and so on. The products have excellent weatherability, UV-resistance, flame-resistance, solvent, oil, chemical, alkali, alcohol resistance. The migration are very low. And the low temperature performances are very good, so they can be used in cold area and high-rise building. We can adjust the formulation according to the customers’ requirements, such as hardness, flame-retardant, UV-resistance etc. ♦ Variety Colours  ♦ Workshop show

♦ Workshop show

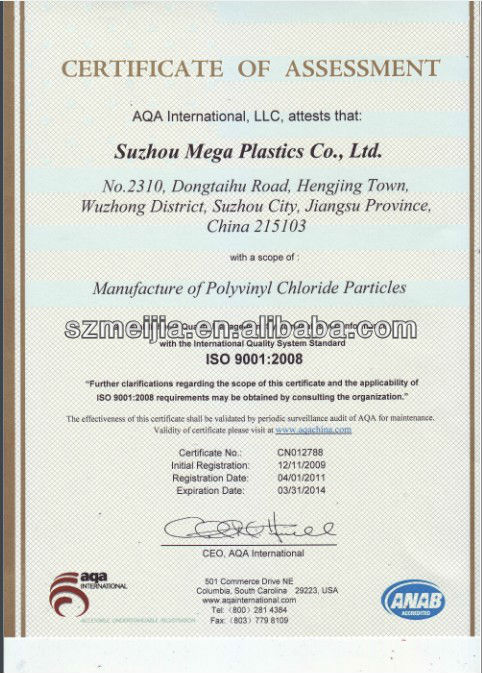

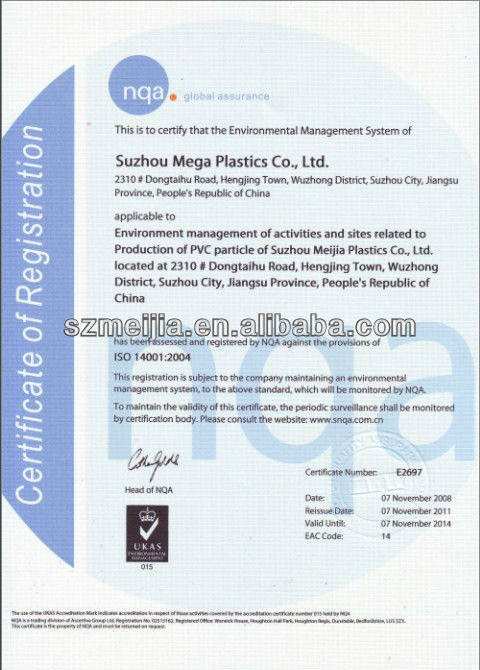

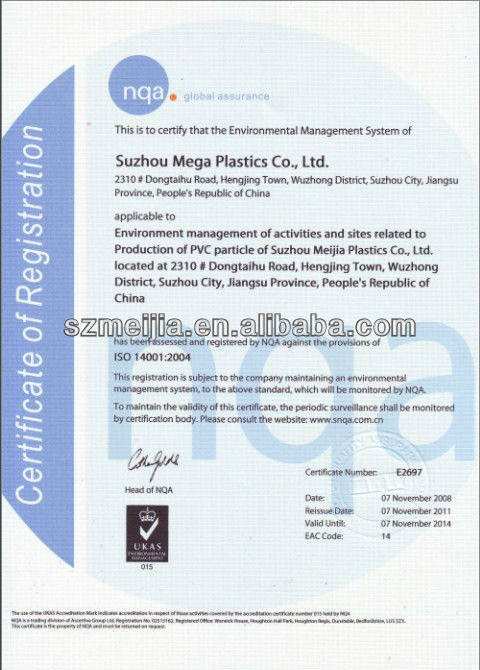

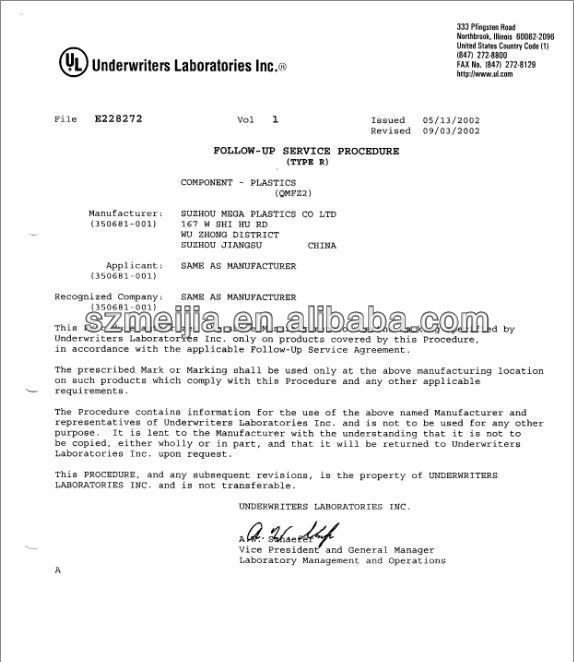

♦ Company Certifications:

♦ Company Certifications:  ◊ ISO 9001:2008

◊ ISO 9001:2008  ◊ ISO 14001:2004

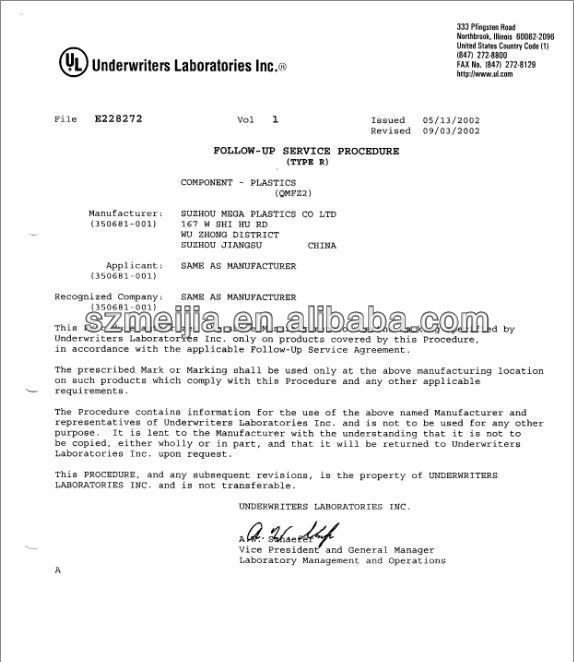

◊ ISO 14001:2004  ◊ Certification of UL

◊ Certification of UL

2. UV resistance

3. Flame-retardant

4. Environmental friendly

5. Low temperature properties

GL 1 Sealing strips for glass of low-rise and mid-rise building GL 2 Sealing strips for glass of high-rise and cold area We 1 Sealing strips for window profile of low-rise and mid-rise building We 2 Sealing strips for window profile of high-rise and cold area

Test Items | Unit | Technical Requirements | ||||

GL 1 | GL 2 | We 1 | WE 2 | |||

| Hardness (Shore A) | 25°C | A | 65±5 | 60±5 | 60±5 | 60±5 |

0°C | ≤85 | ≤75 | ≤85 | ≤75 | ||

-40°C | ≤50 | ≤45 | ≤45 | ≤45 | ||

Difference of hardness between 0 and-40°C | ≤30 | ≤15 | ≤30 | ≤15 | ||

Modulus at 100% | MPa | ≥3.0 | ≥2.0 | ≥3.0 | ≥2.0 | |

Tensile strength | MPa | ≥7.5 | ≥10.0 | ≥7.5 | ≥10.0 | |

Elongation at break | % | ≥300 | ≥300 | ≥300 | ≥300 | |

Oven aging condition | °C·h | 100×72 | ||||

Minimum percent of unaged value |

| |||||

Tensile strength, percent | % | ≥85 | ≥85 | ≥85 | ≥85 | |

Elongation, percent | % | ≥70 | ≥70 | ≥70 | ≥70 | |

Weight loss | % | ≤3.0 | ≤3.0 | ≤3.0 | ≤3.0 | |

Shrinkage after aging, 70°C×24h | % | ≤2.0 | ≤2.0 | ≤2.0 | ≤2.0 | |

| Compression set, 70°C×24h (compression ratio 30%) | % | ≤75 | ≤75 | ≤75 | ≤75 | |

Low temperature brittleness | °C | -30 | -40 | -30 | -40 | |

♦ Workshop show

♦ Workshop show

♦ Company Certifications:

♦ Company Certifications:  ◊ ISO 9001:2008

◊ ISO 9001:2008  ◊ ISO 14001:2004

◊ ISO 14001:2004  ◊ Certification of UL

◊ Certification of UL Related Keywords

Related Keywords