halogen free flame retardant 105 xlpe granules

- Delivery Time:

- 5 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China (Mainland) |

|---|

Product Description

Product Description

Specifications 1.xlpe crosslinkable

2.Good plasticization

3.LSZH UL power cable insulation compound

4.No significant impurities

Introduction:

Irradiation cross-linkable flame-retardant polyolefin low-Smoke non-halogen compound is based on polyolefin resin, which is mixed with non-halogen flame retardant, cross-linkable agent, and other process agent, to knead, plastify, and then extrude into pellets. It has excellent mechanical property, oil resistance, electirc property, flame-retardant property and processing properties. Moreover, it features the advantage of no halogen and low smoke amount giving out, which can be used in power cable, control cable, marine cable, optical cable and signal cable etc.

MG80017-90(J/H) 90°C irradiation cross-likable Flame-retardant polyolefin low-Smoke non-halogen insulating(sheating) compound MG80017-105(J/H) 105°Cirradiation cross-linkable Flame-retardant polyolefin low-Smoke non-halogen insulating(sheating) compound MG80017-125(J/H) 125°C irradiation cross-linkable Flame-retardant polyolefin low-Smoke non-halogen insulating(sheating) compound

Irradiation dosage:

Irradiation dosage is different from the cable and da, genlerally 10-15MRAD recommended. 1.About us In 2001,we began to develop the environmental conscientious polymer compound for our cable and wire customers.Now we are accepted as a lead manufacturer of flexible vinyl compound and LSHF compound in China mainland market.We formulate more than 20,000 tons Rosh complaisant compund each year for demostics and oversea market. 2.Products application Apart from being widely used in the cable and wire industry, Mega polymer compounds have a variety of other applications in the market, such as automotive, tool handle, toys, medical tubing, and other industrial and residential applications.

For each application, our engineers from Mega will design particular formulation and process to meet each requirement of the compound including hardness, color and cost. They will co_operate closely with customers to make sure that each secification of the compound to be met. 3.Expertise Vinyl resin is an extremely versatile thermoplastic polymer suitable for a wide range of applications. Vinyl resin attains its usefulness through various additives that allow it to be used in a multitude of markets and products – everything from automotive parts to medical tubing, from building and construction to children's toys. Vinyl is very durable, relatively cost efficient and meets stringent regulations and requirements mandated by many industries 4.Laboratory

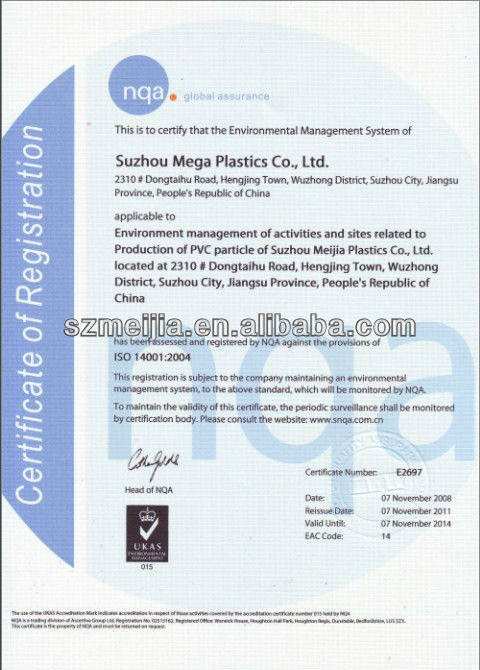

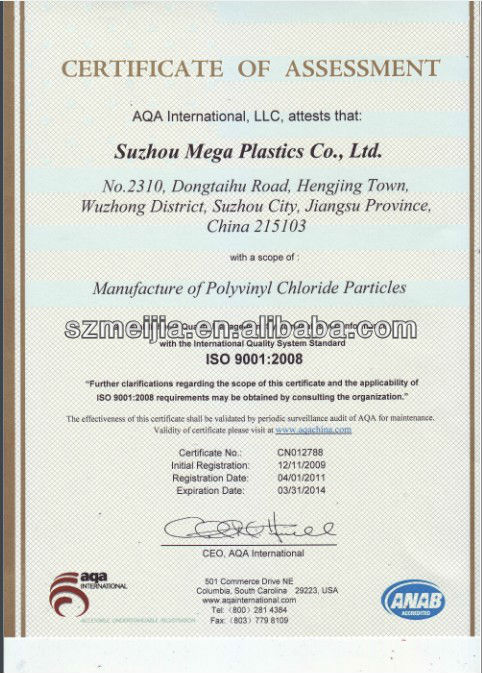

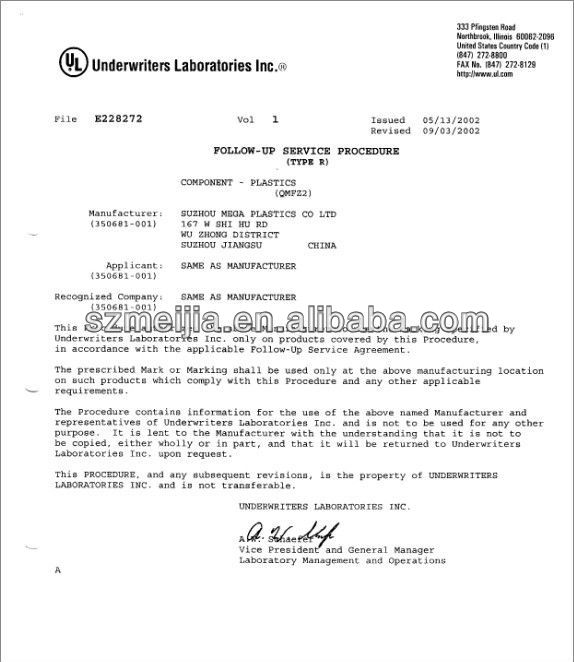

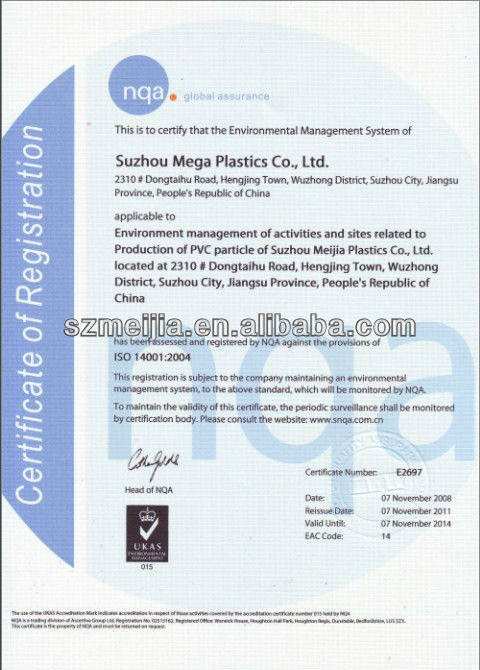

Mega highskilled staff and wellequipped laboratory ensure the compound be tested both on design stage and process spot , so that to keep the products consistently meet each customer's unique requirements. Now we can undergo such testing items: tensile strength, elongation, gravity, air oven aging, pad volume resistivity , heat stability, flame-retardant (Oxygen Index), melt flow analysis, air oven aging, color meter, water resistance, oil resistance. Mega also uses atomic absorption spectrometry (AA) and X-Ray spectrometry to analyze environmental sensitive elements of raw material , so as to ensure they are RoSH compliant. 5.Industry Listings and Certifications:

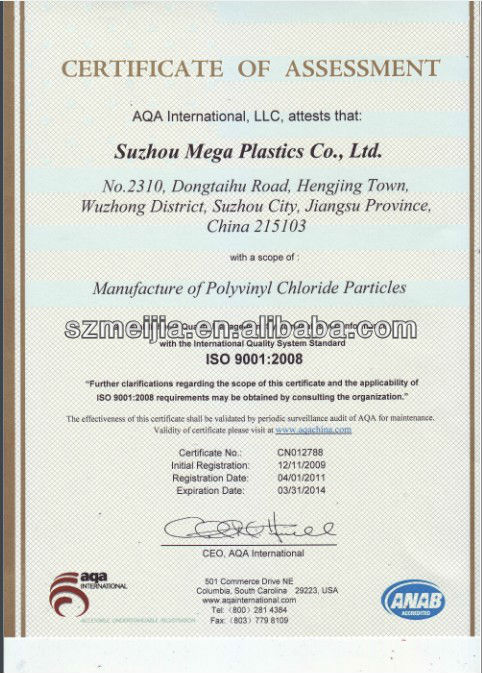

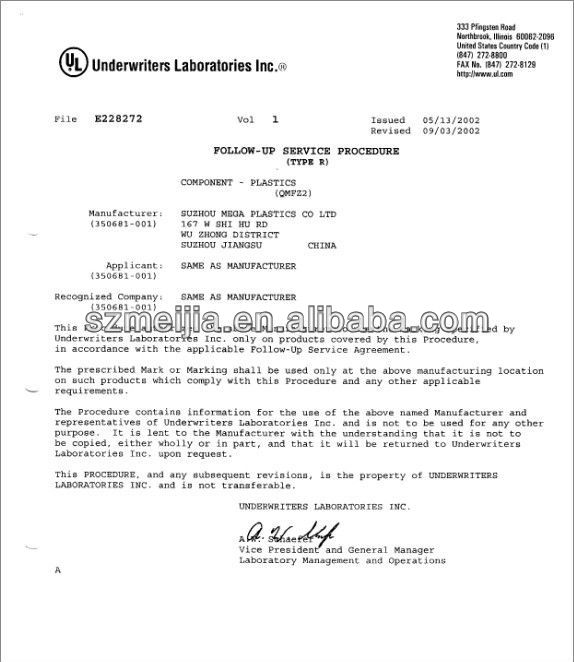

Product Safety: UL, CSA, VDE & CCC

Quality Management System: ISO9001-2004

Environment Management: ISO14001-2004 6.Remark If you want to get more information about the products or establish business relationship with us, please feel free to contact us. Tel: 86-512-65275752 / 86-Fax: 86-512-65277403 Phone:+86-13404235070 Homepage:www.megaplastics.com 7.Green compliancy Mega is extremely conscientious about providing customers with accurate information about our products and processes relating to environmental compliancy and established industry specifications and standards. We are pride on working with each customer to address their specific product and market needs. We will remain committed to finding new ways to formulate traditional and new compounds with minimal or no defined hazardous ingredients, as well as offer more eco-friendly alternatives whenever possible. Compliance will continue to be a Mega core competency as new research and regulations evolve around the world for vinyl and other plastics. 8.Mega office 8.Mega workshop

8.Mega workshop  9.Variety Colours

9.Variety Colours  10.Laboratory

10.Laboratory

11.CERTIFICATIONS

2.Good plasticization

3.LSZH UL power cable insulation compound

4.No significant impurities

Introduction:

Irradiation cross-linkable flame-retardant polyolefin low-Smoke non-halogen compound is based on polyolefin resin, which is mixed with non-halogen flame retardant, cross-linkable agent, and other process agent, to knead, plastify, and then extrude into pellets. It has excellent mechanical property, oil resistance, electirc property, flame-retardant property and processing properties. Moreover, it features the advantage of no halogen and low smoke amount giving out, which can be used in power cable, control cable, marine cable, optical cable and signal cable etc.

MG80017-90(J/H) 90°C irradiation cross-likable Flame-retardant polyolefin low-Smoke non-halogen insulating(sheating) compound MG80017-105(J/H) 105°Cirradiation cross-linkable Flame-retardant polyolefin low-Smoke non-halogen insulating(sheating) compound MG80017-125(J/H) 125°C irradiation cross-linkable Flame-retardant polyolefin low-Smoke non-halogen insulating(sheating) compound

| Test Items | Unit | Typical Value | ||

| MG80017-90(J/H) | MG80017-105(J/H) | MG80017-125(J/H) | ||

| Density(23°C) | g/cm3 | 1.45 | 1.44 | 1.45 |

| Tensile strength | MPa | 12.3 | 12.7 | 13.1 |

| Elongation at break | % | 220 | 210 | 200 |

| Hot setting test | 200°C x 15min,0.2MPa | |||

| Elongation under lood | % | 65 | 70 | 80 |

| Permanent elongation after cooling | °Cxh | 121x168 | 136x168 | 158x168 |

| Retaintion of Tensile strength | % | 109 | 112 | 110 |

| Retaintion of Elongation at break | % | 89 | 87 | 85 |

| low temperature impact Brittleness | °C | -25 pass | -25 pass | -25 pass |

| 20°C Volume resistivity | Ω.cm | 5.6x1014 | 3.7x1014 | 4.5x1014 |

| Dielectirc strength | MV/m | 26 | 28 | 27 |

| Oxygen index | % | 34 | 35 | 33 |

| Acid gas emission | mg/g | 0 | 0 | 0 |

| pH | 5.9 | 6.0 | 5.8 | |

| Conductivity | μs/mm | 0.8 | 0.7 | 0.5 |

| Dm(1.0mm) Smoke density | flame | 56 | 61 | 54 |

| non-flame | 152 | 159 | 162 | |

Irradiation dosage:

Irradiation dosage is different from the cable and da, genlerally 10-15MRAD recommended. 1.About us In 2001,we began to develop the environmental conscientious polymer compound for our cable and wire customers.Now we are accepted as a lead manufacturer of flexible vinyl compound and LSHF compound in China mainland market.We formulate more than 20,000 tons Rosh complaisant compund each year for demostics and oversea market. 2.Products application Apart from being widely used in the cable and wire industry, Mega polymer compounds have a variety of other applications in the market, such as automotive, tool handle, toys, medical tubing, and other industrial and residential applications.

For each application, our engineers from Mega will design particular formulation and process to meet each requirement of the compound including hardness, color and cost. They will co_operate closely with customers to make sure that each secification of the compound to be met. 3.Expertise Vinyl resin is an extremely versatile thermoplastic polymer suitable for a wide range of applications. Vinyl resin attains its usefulness through various additives that allow it to be used in a multitude of markets and products – everything from automotive parts to medical tubing, from building and construction to children's toys. Vinyl is very durable, relatively cost efficient and meets stringent regulations and requirements mandated by many industries 4.Laboratory

Mega highskilled staff and wellequipped laboratory ensure the compound be tested both on design stage and process spot , so that to keep the products consistently meet each customer's unique requirements. Now we can undergo such testing items: tensile strength, elongation, gravity, air oven aging, pad volume resistivity , heat stability, flame-retardant (Oxygen Index), melt flow analysis, air oven aging, color meter, water resistance, oil resistance. Mega also uses atomic absorption spectrometry (AA) and X-Ray spectrometry to analyze environmental sensitive elements of raw material , so as to ensure they are RoSH compliant. 5.Industry Listings and Certifications:

Product Safety: UL, CSA, VDE & CCC

Quality Management System: ISO9001-2004

Environment Management: ISO14001-2004 6.Remark If you want to get more information about the products or establish business relationship with us, please feel free to contact us. Tel: 86-512-65275752 / 86-Fax: 86-512-65277403 Phone:+86-13404235070 Homepage:www.megaplastics.com 7.Green compliancy Mega is extremely conscientious about providing customers with accurate information about our products and processes relating to environmental compliancy and established industry specifications and standards. We are pride on working with each customer to address their specific product and market needs. We will remain committed to finding new ways to formulate traditional and new compounds with minimal or no defined hazardous ingredients, as well as offer more eco-friendly alternatives whenever possible. Compliance will continue to be a Mega core competency as new research and regulations evolve around the world for vinyl and other plastics. 8.Mega office

8.Mega workshop

8.Mega workshop  9.Variety Colours

9.Variety Colours  10.Laboratory

10.Laboratory

11.CERTIFICATIONS

Related Keywords

Related Keywords