Flame-retardant low smoke non-halogen polyolefin filling (bedding) compound for wire/cable

- Delivery Time:

- 7 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Jiangsu, China (Mainland) |

|---|

Product Description

Product Description

Specifications 1. Environmental friendly

2. Permagent properties

3. Great electric performance

4. Perfect flame-retardant

MG80012(J) Flame-retardant polyolefin low-Smoke non-halogen insulating compound

MG80012(H) Flame-retardant polyolefin low-Smoke non-halogen sheathing compound

MG80011(G) Flame-retardant polyolefin low-Smoke non-halogen filling (bedding) compound Flame-retardant polyolefin low-Smoke non-halogen compound can be used for power cable, telecommunication & electrical cable, control cable, ship cable, light-fiber cable etc. It mainly applied in such large public facilities that require flame-retardant equipment as underground, nuclear power station, tall building and airport. It has good processing performance and flame-retardant properties, Working temperature is from 70 to 90°C.

♦ Variety Colours  ♦ Workshop show

♦ Workshop show

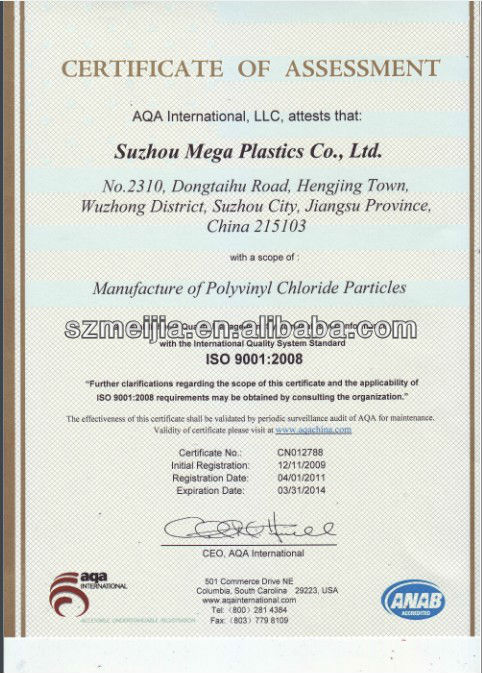

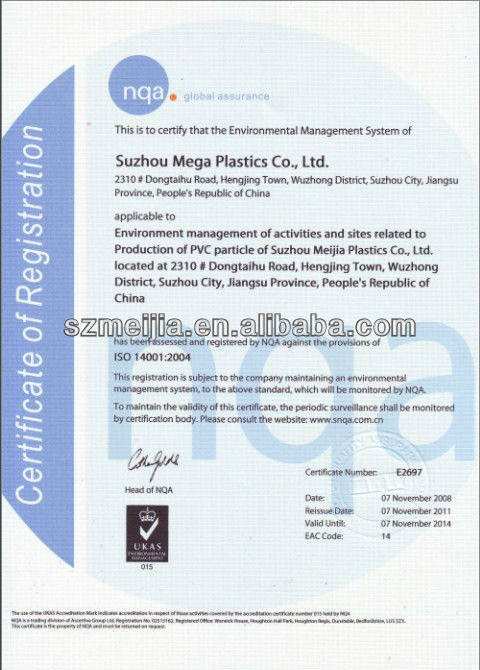

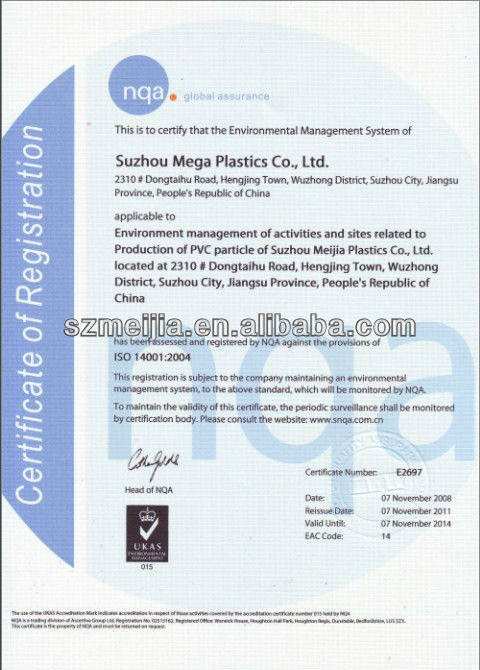

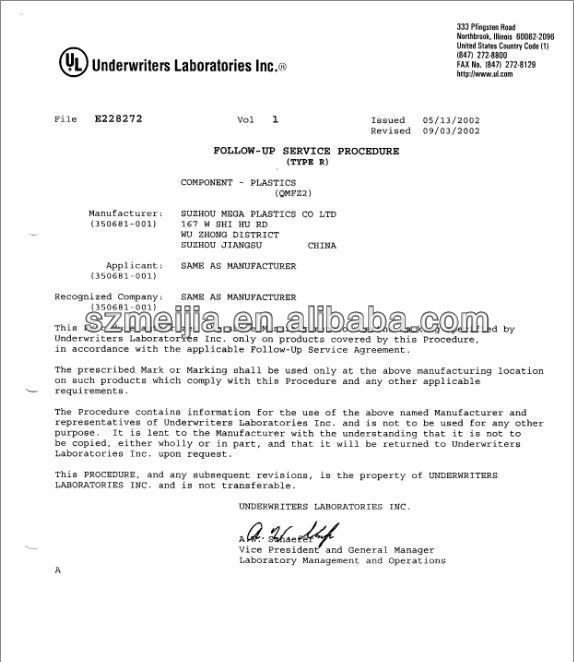

♦ Company Certifications:

♦ Company Certifications:  ◊ ISO 9001:2008

◊ ISO 9001:2008  ◊ ISO 14001:2004

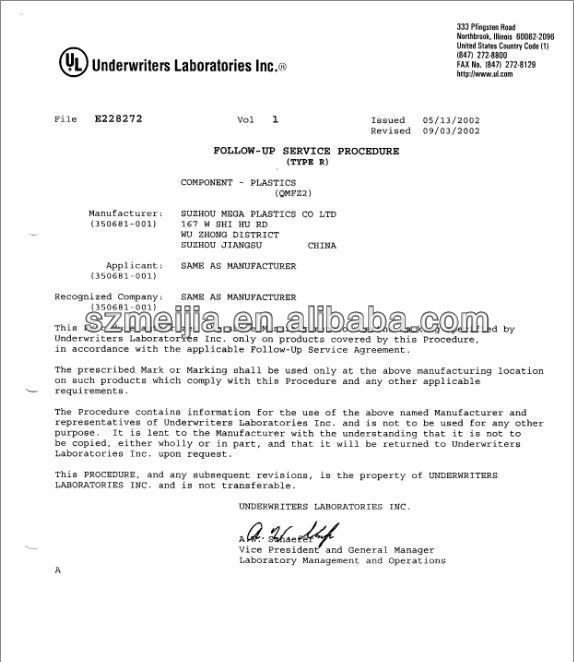

◊ ISO 14001:2004  ◊ Certification of UL

◊ Certification of UL

2. Permagent properties

3. Great electric performance

4. Perfect flame-retardant

MG80012(J) Flame-retardant polyolefin low-Smoke non-halogen insulating compound

MG80012(H) Flame-retardant polyolefin low-Smoke non-halogen sheathing compound

MG80011(G) Flame-retardant polyolefin low-Smoke non-halogen filling (bedding) compound Flame-retardant polyolefin low-Smoke non-halogen compound can be used for power cable, telecommunication & electrical cable, control cable, ship cable, light-fiber cable etc. It mainly applied in such large public facilities that require flame-retardant equipment as underground, nuclear power station, tall building and airport. It has good processing performance and flame-retardant properties, Working temperature is from 70 to 90°C.

Test Items | Unit | Typical Value | ||

MG80012(J) | MG80012(H) | MG80011(G) | ||

Density | g/cm³ | 1.47 | 1.46 | 1.60 |

Tensile strength | MPa | 12.3 | 11.7 | 10.2 |

Elongation at break | % | 190 | 180 | 100 |

Air oven again | °C×h | 100×168 | 100×168 | - |

Tensile strength after again | 13.5 | 12.8 | - | |

Variability of Tensile strength | % | +10 | +9.4 | - |

Elongation at break after again | 168 | 155 | - | |

Variability of Elongation at break | % | -11.5 | -13.9 | - |

low temperature impact Brittleness | °C | -25 pass | -25 pass | - |

20°C Volume resistivity | Ω·cm | 5.1×1014 | 1.5×1013 | - |

Dielectric strength | MV/m | 28 | 27 | - |

Oxygen index | % | 34 | 35 | 45 |

HCI Acid gas emission | mg/g | 0 | 0 | 0 |

PH | 6.0 | 6.3 | 5.4 | |

Conductivity | μ s/mm | 0.4 | 0.6 | 1.0 |

(1.0mm)Smoke density | flame | 48 | 55 | 64 |

non-flame | 142 | 151 | 168 | |

♦ Workshop show

♦ Workshop show

♦ Company Certifications:

♦ Company Certifications:  ◊ ISO 9001:2008

◊ ISO 9001:2008  ◊ ISO 14001:2004

◊ ISO 14001:2004  ◊ Certification of UL

◊ Certification of UL Related Keywords

Related Keywords