Cable Grade Low Smoke Low Radiation PVC Compounds

- Delivery Time:

- 7 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Jiangsu, China (Mainland) |

|---|

Product Description

Product Description

Specifications 1. Flame-retardant

2. Suit to wire&cable

3. Permanent performances

4. Eco-friendly

5. Heat-stabilized

Introduction Low-smoke low-halogen flame-retardant PE compound is based on PE, which is mixed with high grade flame retardant, smoke reduction agent and other process agent, to knead, plastify, and then extrude into pellets. It has excellent mechanical properties, flame-retardant property and processing properties. It can be used in power cable, control cable, optical cable and communication cable etc. MG80018 Low-smoke low-halogen flame-retardant polyolefin compound MG80018-105 105°C radiation cross-linked low-smoke low-halogen flame-retardant polyolefin compound MG80018-125 125°C radiation cross-linked low-smoke low-halogen compound

♦ Variety Colours  ♦ Workshop show

♦ Workshop show

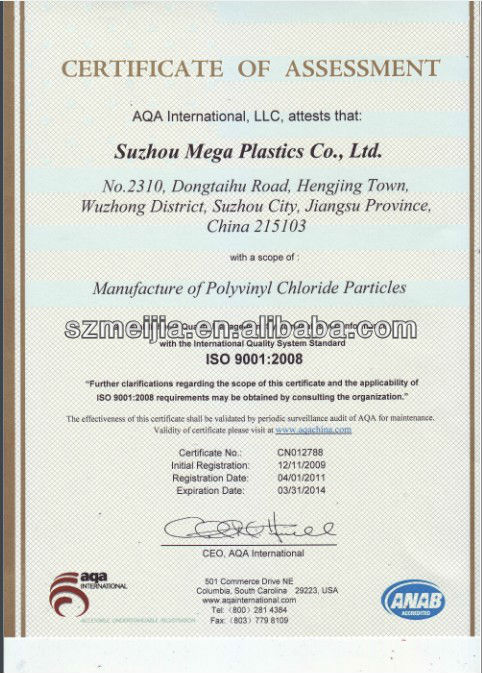

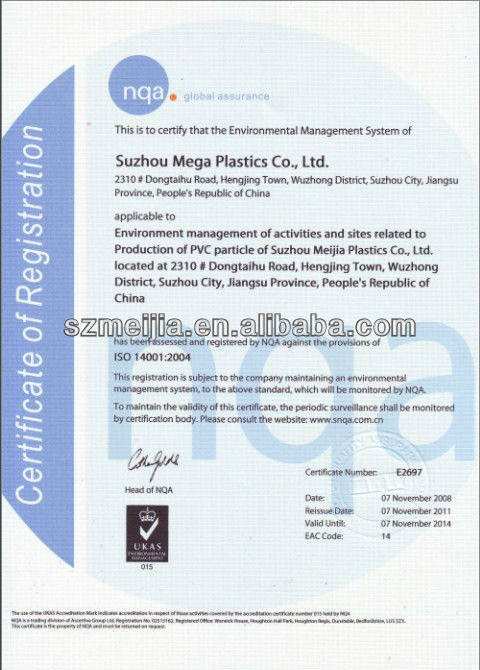

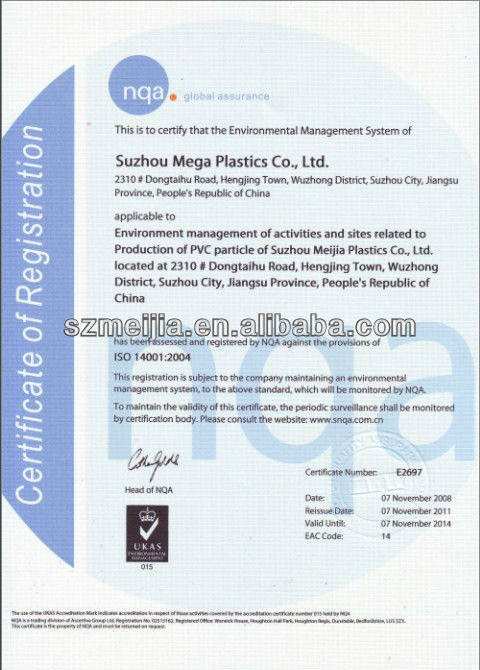

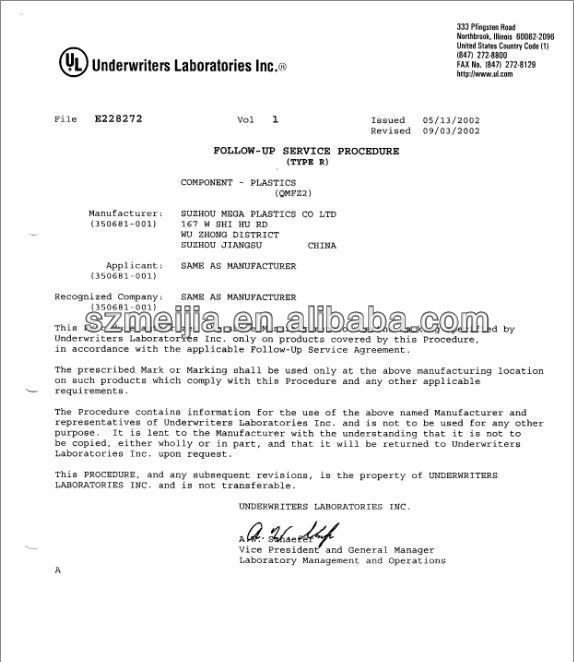

♦ Company Certifications:

♦ Company Certifications:  ◊ ISO 9001:2008

◊ ISO 9001:2008  ◊ ISO 14001:2004

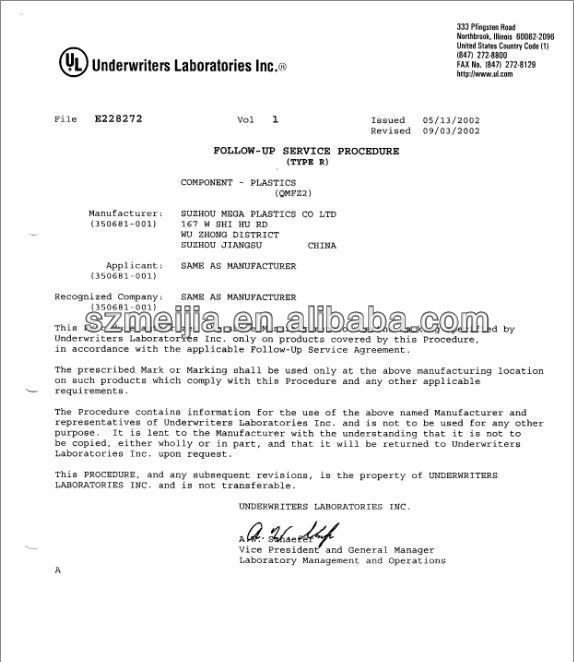

◊ ISO 14001:2004  ◊ Certification of UL

◊ Certification of UL

2. Suit to wire&cable

3. Permanent performances

4. Eco-friendly

5. Heat-stabilized

Introduction Low-smoke low-halogen flame-retardant PE compound is based on PE, which is mixed with high grade flame retardant, smoke reduction agent and other process agent, to knead, plastify, and then extrude into pellets. It has excellent mechanical properties, flame-retardant property and processing properties. It can be used in power cable, control cable, optical cable and communication cable etc. MG80018 Low-smoke low-halogen flame-retardant polyolefin compound MG80018-105 105°C radiation cross-linked low-smoke low-halogen flame-retardant polyolefin compound MG80018-125 125°C radiation cross-linked low-smoke low-halogen compound

Test Items | Unit | Typical Value | ||

MG80018 | MG80018-105 | MG80018-125 | ||

Density(23°C) | g/cm3 | 1.4 | 1.41 | 1.39 |

Tensile strength | MPa | 13.5 | 13.7 | 14.1 |

Elongation at break | % | 220 | 210 | 230 |

Hot setting test | 200°C x 15min, 0.2MPa | |||

Elongation under load | % | - | 90 | 75 |

Oven aging test | °C×h | 100×136 | 136×168 | 158×168 |

Permanent elongation after cooling | % | - | 5 | 6 |

Retention of Tensile strength | % | 110 | 109 | 112 |

Retention of Elongation at break | % | 86 | 88 | 87 |

low temperature brittleness | °C | -25 | -25 | -25 |

20°C Volume resistivity | Ω·cm | 3.6x1013 | 2.6x1013 | 4.1x1013 |

Dielectric strength | MV/m | 28 | 27 | 27 |

Oxygen index | % | 31 | 32 | 31 |

♦ Workshop show

♦ Workshop show

♦ Company Certifications:

♦ Company Certifications:  ◊ ISO 9001:2008

◊ ISO 9001:2008  ◊ ISO 14001:2004

◊ ISO 14001:2004  ◊ Certification of UL

◊ Certification of UL Related Keywords

Related Keywords