Best Price Chemical Paint Metal Bucket Tin Can Side Seam Welding Machine

-

$11000.00≥1 set

- Min. Order:

- 1 set

- Min. Order:

- 1 set

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Payment Type: | T/T |

|---|

Product Description

Product Description

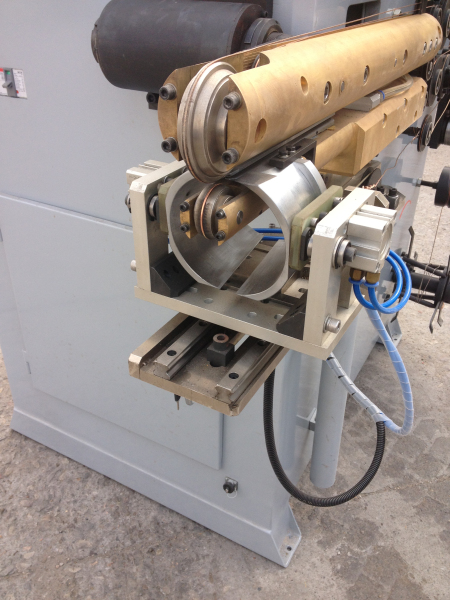

Product Name:chemical paint metal bucket tin can side seam welding machine

Product Paramenters

Model | FN2000-A | FN2000-B | FN2000-C |

Input Power | 3N 380V/50Hz 10KVA | 3N 380V/50Hz 10KVA | 3N 380V/50Hz 16KVA |

Welding Speed | 5~10m/min | 5~10m/min | 5~10m/min |

Productivity | 10cans/min | 20cans/min | 10cans/min |

Diameter Range | Φ105~Φ290mm | Φ52~Φ180mm | Φ105~Φ290mm |

Height | 420mm(500mm) | ≤250mm | 420mm(500mm) |

Welding Thickness | 0.28~0.42mm | 0.18~0.4mm | 0.18~0.5mm |

Overlap | 3~4mm | 2~3mm | 3~4mm |

Copper Wire | Φ1.5 T2 | Φ1.5 T2 | Φ1.5 T2 |

Welding Material | Tinplate | Tinplate | Tinplate/Galvanized |

Net Weight | 1000kg | 1000kg | 1000kg |

Dimension | 2200x1100x1600mm | 2200x1100x1600mm | 2200x1100x1600mm |

Products Description

♦ The equipment is easy to repair,can welding many size of cans.

♦ Mitsubishi PLC and frequency conversion speed governor control system.

♦ Welding current microcomputer control,with the function of gently rise and fall at front and back end of current.

♦ Welding positioning device with upper and lower limit,prevent loose function

♦ Welding pressure, wire storage pressure pressure are have a table show,intuitive and convenient to adjust.

♦ Small can use tiles jig, will non-deformation after welding,better for next procedure.

♦ Galvanized material use double copper wire technique,the copper wire with zinc layer will not reusable,ensure the welding quality, according to the different material,also can use single copper wire welding.

♦ Mitsubishi PLC and frequency conversion speed governor control system.

♦ Welding current microcomputer control,with the function of gently rise and fall at front and back end of current.

♦ Welding positioning device with upper and lower limit,prevent loose function

♦ Welding pressure, wire storage pressure pressure are have a table show,intuitive and convenient to adjust.

♦ Small can use tiles jig, will non-deformation after welding,better for next procedure.

♦ Galvanized material use double copper wire technique,the copper wire with zinc layer will not reusable,ensure the welding quality, according to the different material,also can use single copper wire welding.

Our Advantages

♦ MITSUBISHI or PANASONIC PLC and variable-frequency speed governor from Japan.

♦ OMRON Sensor and photoelectric switch form Japan.

♦ SMC Waterway detected flow switch from Japan.

♦ SKF & NSK bearings from Sweden or Japan.

♦ SCHNEIDER electrical appliance components from France.

♦ LG air switch,contactor and circuit breaker from South Korea.

♦ SEMIKRON & SIEMENS control thyristors from Germany.

♦ OMRON Sensor and photoelectric switch form Japan.

♦ SMC Waterway detected flow switch from Japan.

♦ SKF & NSK bearings from Sweden or Japan.

♦ SCHNEIDER electrical appliance components from France.

♦ LG air switch,contactor and circuit breaker from South Korea.

♦ SEMIKRON & SIEMENS control thyristors from Germany.

Recommend Products

Details Images

Exhibition

2015 Cannex in Guangzhou~2017 Metpack in Germany~2018 Cannex in Guangzhou

Suzhou First Packing Machinery Co.,Ltd.was founded in 1997,It's a professional company which

specialize in designing and manufacturing tin can making equipment,the products are widely used in petroleum,chemical,paint,coating,ventilation duct and etc.

specialize in designing and manufacturing tin can making equipment,the products are widely used in petroleum,chemical,paint,coating,ventilation duct and etc.

Related Keywords

Related Keywords

You May Also Like

You May Also Like