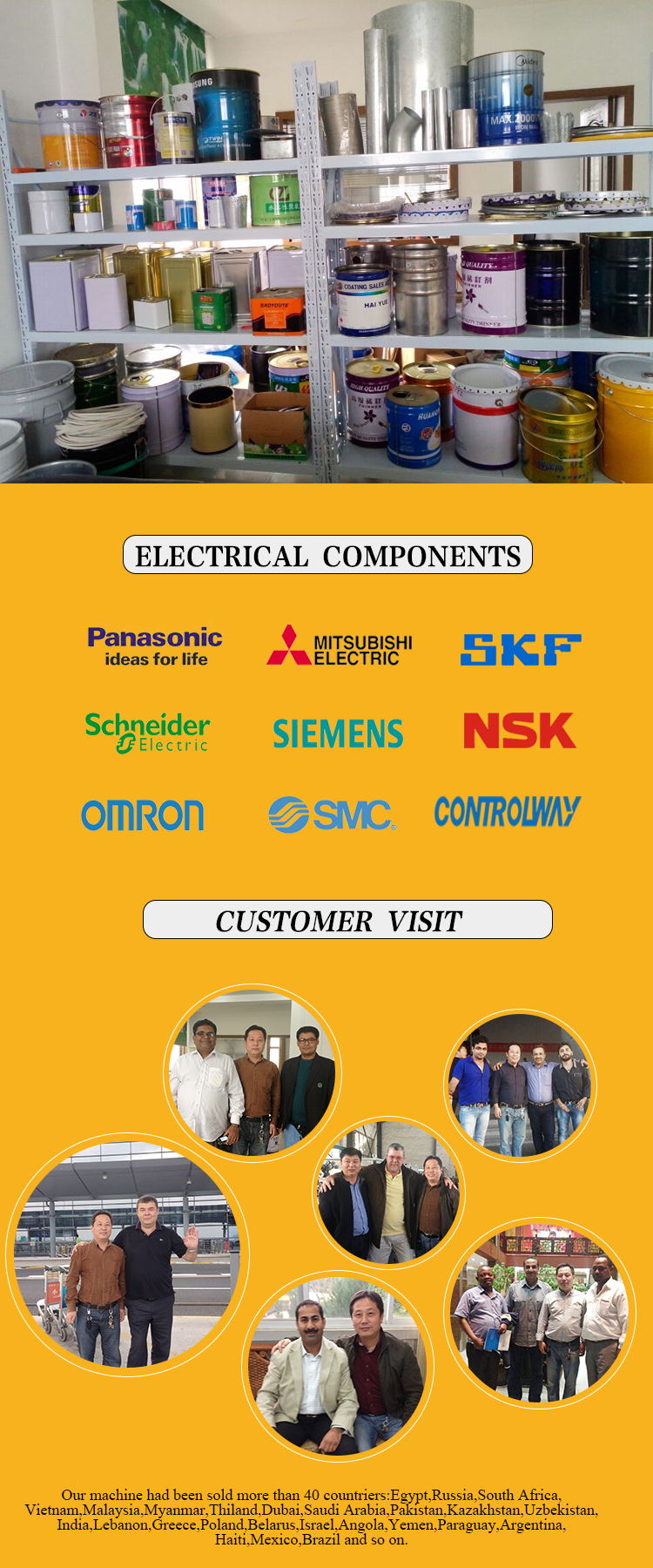

Product:Cans,Pails,Drums or Irregularly Shaped Containers

Size:0.25~25Liter

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 100 Set/Sets per Year |

|---|---|

| Payment Type: | L/C,D/P |

| Port: | Shanghai |

Model | FN2000-A | FN2000-B | FN2000-C |

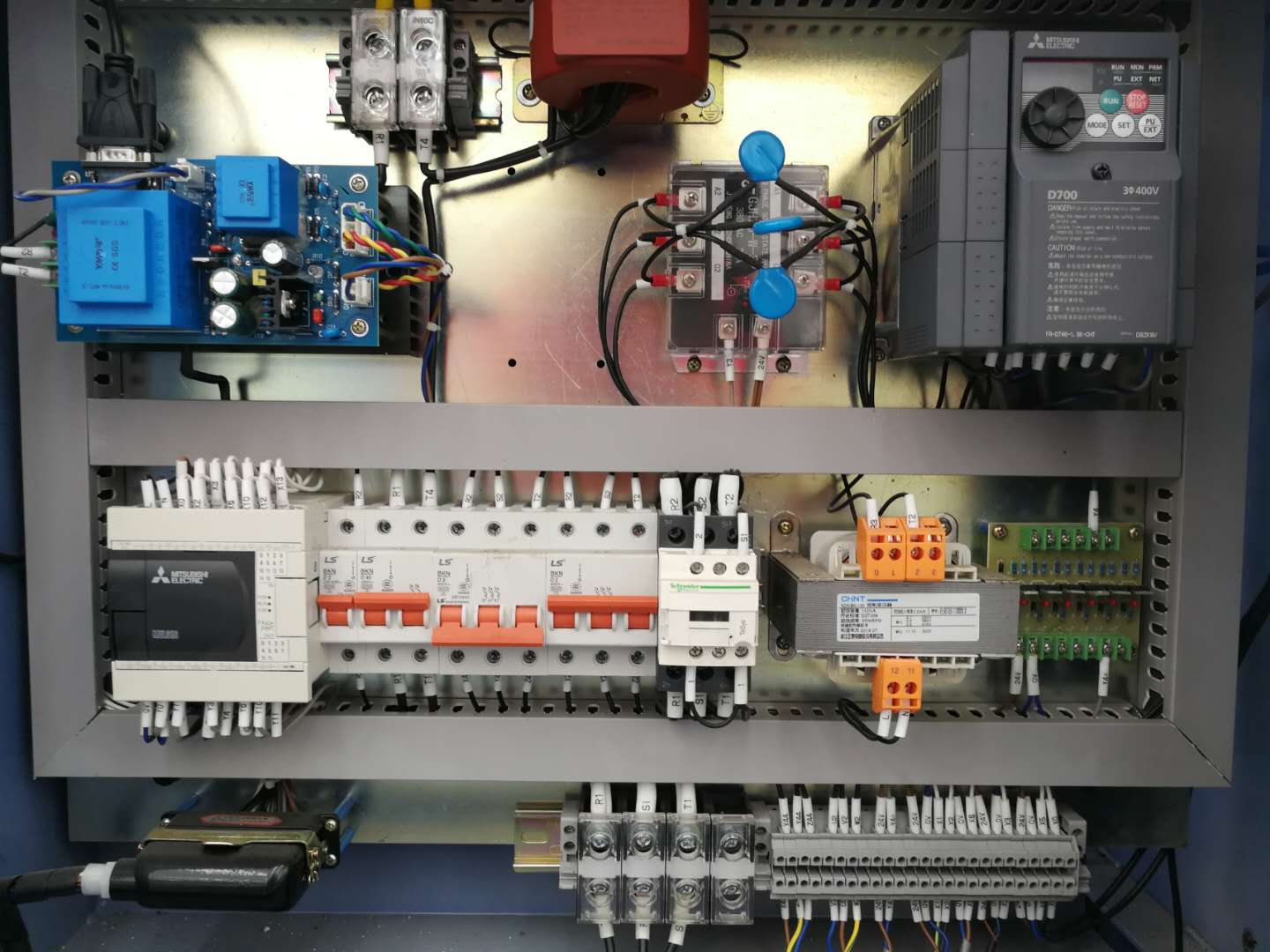

Input Power | 3N 380V/50Hz 10KVA | 3N 380V/50Hz 10KVA | 3N 380V/50Hz 16KVA |

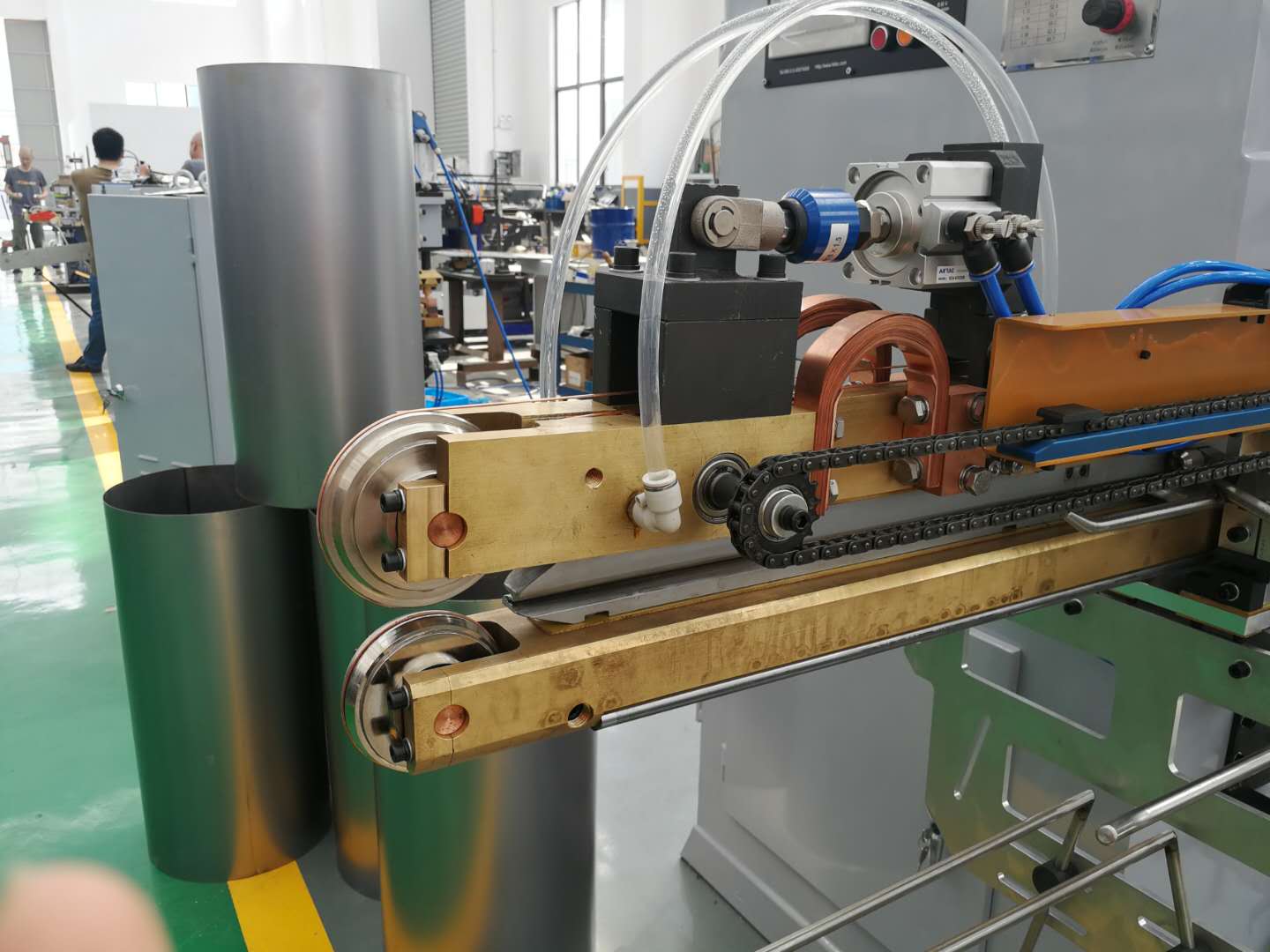

Welding Speed | 5~10m/min | 5~10m/min | 5~10m/min |

Productivity | 10cans/min | 20cans/min | 10cans/min |

Diameter Range | Φ105~Φ290mm | Φ52~Φ180mm | Φ105~Φ290mm |

Height | 420mm(500mm) | ≤250mm | 420mm(500mm) |

Welding Thickness | 0.28~0.42mm | 0.18~0.4mm | 0.28~0.5mm |

Overlap | 3~4mm | 2~3mm | 3~4mm |

Copper Wire | Φ1.5 T2 | Φ1.5 T2 | Φ1.5 T2 |

Welding Material | Tinplate | Tinplate | Tinplate/Galvanized |

Net Weight | 1000kg | 1000kg | 1000kg |

Dimension | 2200x1100x1600mm | 2200x1100x1600mm | 2200x1100x1600mm |

Related Keywords