PSA Nitrogen Generation Unit

- Delivery Time:

- 45 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Jiangsu, China (Mainland) |

|---|

Product Description

Product Description

PSA Nitrogen Generation Unit

Whether your company is specialized in , electronics, heat treatment, metallurgy, glasses,petrochemical,medicine,chemical manufacturing, or food and beverage, a dependable supply of industrial gas of Nitrogen is crucial. Compared to the on-demand delivery of gas bottles or tanks, on-site production of nitrogen offers a wealth of advantages ranging from cost savings to continuous availability. This is exactly what we can provide for you. Our advanced PSA nitrogen generating unit offer you the ultimate solution: flexible on-site production of industrial nitrogen at the lowest possible cost. Benefits of Nitrogen generator by PSA Independent supply of nitrogen Non-stop availability: 24 hours a day, 7 days a week. Significant economies of scale and lower operational costs: No safety hazards when handling high-pressure cylinders. Easy integration within existing compressed air installations High reliability--proven technology: simple, reliable and durable.

The exact purity your application demands.

Low operating costs . What is PSA ? It is a technology used to generate gaseous Nitrogen on-site. Carbon Molecular Sieve (CMS) adsorbs oxygen and water vapor molecules under high pressure - while allowing Nitrogen to pass through,so that nitrogen is separated from the air. Skid-mounted units can be supplied according to customer's requirements. Technological Process

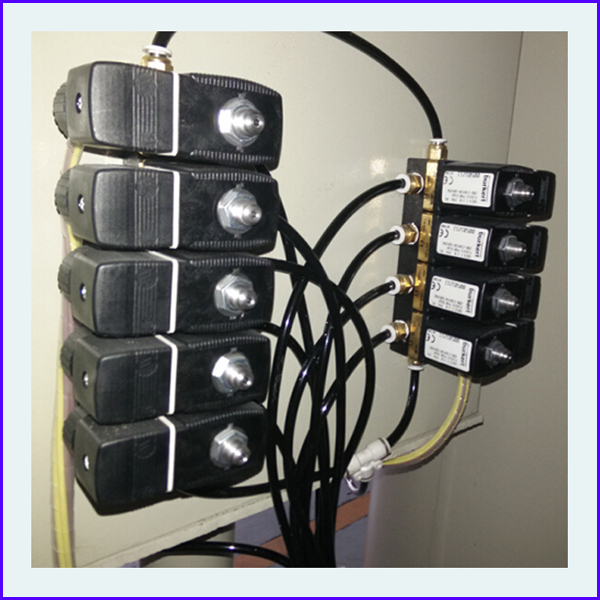

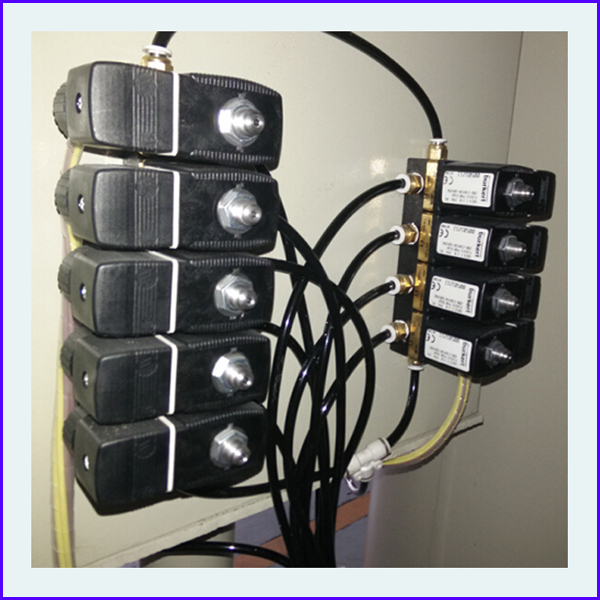

Nitrogen generator by PSA from our company are designed and manufactured based on the principle of Pressure Swing Adsorption(PSA). Ambient air, having being compressed and purified to remove oil, water and dust, enters the adsoption swing adsorping device with two adsorption towers filled with carcon molecular sieve(CMS). The compressed air flow to the adsorption tower from the bottom to up. In the process, oxygen molecular is adsorbed, while nitrogen flows out of the upper side of adsorption tower and then enters then buffer tank for impure nitrogen. After a period of time, the CMS in the adsorption tower is saturated by the oxygen adsorbed. At this time, regeneration is needed. It is realized by stopping adsorbing step and reduce pressure in the adsorption tower. Adsorption and regeneration are conducted alternatively in the two adsorption towers to ensure the consecutive output of nitrogen gas. The whole system components The whole nitrogen generation system mainly consists of the air compressor, the compressed air receiver, filters, refrigeration dryer, the PSA nitrogen generator, and the nitrogne receiving tank. For the air compressor, famous brand such as the Atlas Copco, the Ingersoll Rand can be available from our company to match the PSA nitrogen generators. For filters, the elements with brand of Hankison, Domnick are available. For refrigeration dryer, we have J.mec, the first brand within China, also Hanzhou Union Filter the professional manufacturer of dryer and filters. Enhancement:To ensure the better quality and longer service life, the main parts such as CMS and PLC, we use world famous brand Japan Takeda and MITSUBISHI, for valves, we use Germany Burkert solenoid valves and pneumatic valves. The following mentioned includes the wide application of the nitrogen generator

Food & beverage (storage & packaging). Pharmaceutical applications.

Plastic injection molding.

Electronics.

Laser cutting.

Semiconductor manufacturing.

Chemical applications.

Metal heat treatment. Glass industries. Powder metallurgy If you are in one of these industries and in need of nitrogen generator, welcome to us, we can offer one-stop purchase for your turnkey solutions. FAQ What is the service life of Carbon molecular sieves(CMS) Usually, for normally use, the life span of the CMS is about 5 to 8 years. What is the cycle time to replace the filter element? Usually, the filter element needs to be replaced for every 6 to 8 months. Come to us, if you want to make your own nitrogen!

|

Model | Capacity (Nm³/h) | Feed Gas | Product gas:nitrogen gas | |||||

| Pressure (Mpa) | Dew point (℃) | Residual oil (ppm) | Dew point (℃) | Purity (%) | Pressure (Mpa) | Temperature | ||

XRFD98 |

5-2000 |

0.7-1.0 |

≤-17 |

≤0.003 |

≤-40 | ≥98 |

0.6-0.9 |

Ambient temperature |

XRFD29 | ≥99 | |||||||

XRFD295 | ≥99.5 | |||||||

XRFD39 | ≥99.9 | |||||||

XRFD49 | ≥99.99 | |||||||

The exact purity your application demands.

Low operating costs . What is PSA ? It is a technology used to generate gaseous Nitrogen on-site. Carbon Molecular Sieve (CMS) adsorbs oxygen and water vapor molecules under high pressure - while allowing Nitrogen to pass through,so that nitrogen is separated from the air. Skid-mounted units can be supplied according to customer's requirements. Technological Process

Nitrogen generator by PSA from our company are designed and manufactured based on the principle of Pressure Swing Adsorption(PSA). Ambient air, having being compressed and purified to remove oil, water and dust, enters the adsoption swing adsorping device with two adsorption towers filled with carcon molecular sieve(CMS). The compressed air flow to the adsorption tower from the bottom to up. In the process, oxygen molecular is adsorbed, while nitrogen flows out of the upper side of adsorption tower and then enters then buffer tank for impure nitrogen. After a period of time, the CMS in the adsorption tower is saturated by the oxygen adsorbed. At this time, regeneration is needed. It is realized by stopping adsorbing step and reduce pressure in the adsorption tower. Adsorption and regeneration are conducted alternatively in the two adsorption towers to ensure the consecutive output of nitrogen gas. The whole system components The whole nitrogen generation system mainly consists of the air compressor, the compressed air receiver, filters, refrigeration dryer, the PSA nitrogen generator, and the nitrogne receiving tank. For the air compressor, famous brand such as the Atlas Copco, the Ingersoll Rand can be available from our company to match the PSA nitrogen generators. For filters, the elements with brand of Hankison, Domnick are available. For refrigeration dryer, we have J.mec, the first brand within China, also Hanzhou Union Filter the professional manufacturer of dryer and filters. Enhancement:To ensure the better quality and longer service life, the main parts such as CMS and PLC, we use world famous brand Japan Takeda and MITSUBISHI, for valves, we use Germany Burkert solenoid valves and pneumatic valves. The following mentioned includes the wide application of the nitrogen generator

Food & beverage (storage & packaging). Pharmaceutical applications.

Plastic injection molding.

Electronics.

Laser cutting.

Semiconductor manufacturing.

Chemical applications.

Metal heat treatment. Glass industries. Powder metallurgy If you are in one of these industries and in need of nitrogen generator, welcome to us, we can offer one-stop purchase for your turnkey solutions. FAQ What is the service life of Carbon molecular sieves(CMS) Usually, for normally use, the life span of the CMS is about 5 to 8 years. What is the cycle time to replace the filter element? Usually, the filter element needs to be replaced for every 6 to 8 months. Come to us, if you want to make your own nitrogen!

Related Keywords

Related Keywords