99.9% Nitrogen purity PSA nitrogen generation system

- Delivery Time:

- 45 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Jiangsu, China (Mainland) |

|---|

Product Description

Product Description

99.9% Nitrogen purity PSA nitrogen generation system

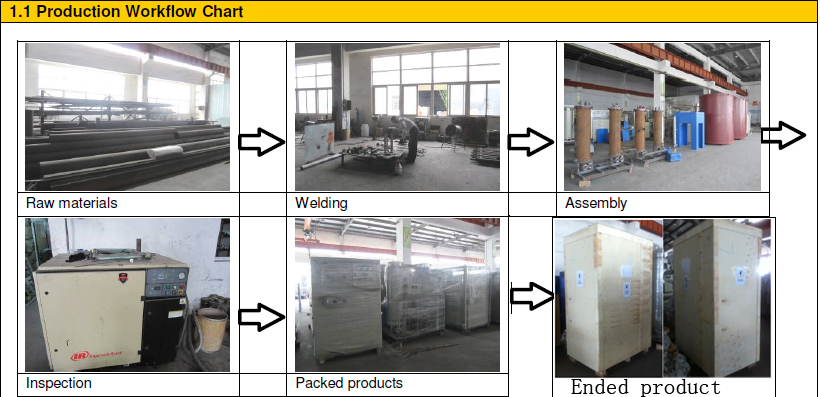

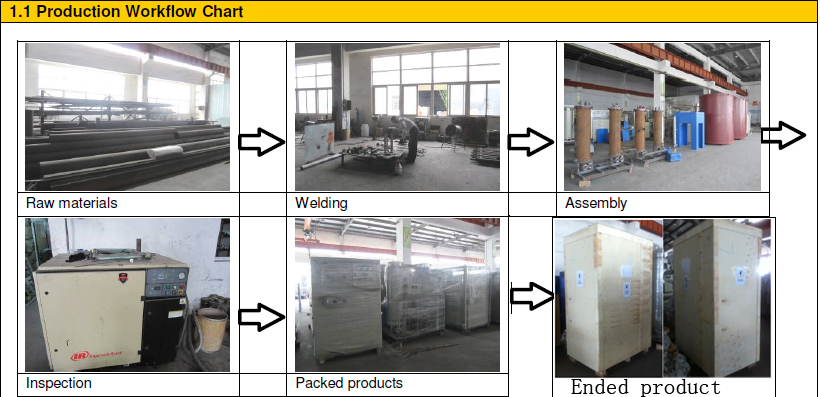

Applications of PSA nitrogen generator Nitrogen is widely used throughout the industries. Plenty of applications can benefit from this kind of on-site gas generation method. General Industry: Nitrogen is used in many metal heat treatment activities like annealing, hardening, sintering. And also for welding, brazing and soldering. Plastic Injection Molding In plastic injection molding nitrogen is often used as the assist gas that prevents oxidation of the plastic that leaves the mold with a clean surface finish. Nitrogen is also injected with the plastic creating air channels which results in less plastic needed without cutting the strength. Food and Beverage Packaging Nitrogen is used at different stages in the production, handling and packing of beverages. Because of its inert, colorless and odorless characteristics, it is used to displace or replace the air to reduce the risk of deterioration of the properties of the end product. Nitrogen generator production line:

Applications of PSA nitrogen generator Nitrogen is widely used throughout the industries. Plenty of applications can benefit from this kind of on-site gas generation method. General Industry: Nitrogen is used in many metal heat treatment activities like annealing, hardening, sintering. And also for welding, brazing and soldering. Plastic Injection Molding In plastic injection molding nitrogen is often used as the assist gas that prevents oxidation of the plastic that leaves the mold with a clean surface finish. Nitrogen is also injected with the plastic creating air channels which results in less plastic needed without cutting the strength. Food and Beverage Packaging Nitrogen is used at different stages in the production, handling and packing of beverages. Because of its inert, colorless and odorless characteristics, it is used to displace or replace the air to reduce the risk of deterioration of the properties of the end product. Nitrogen generator production line:  Nitrogen generator system general flow:

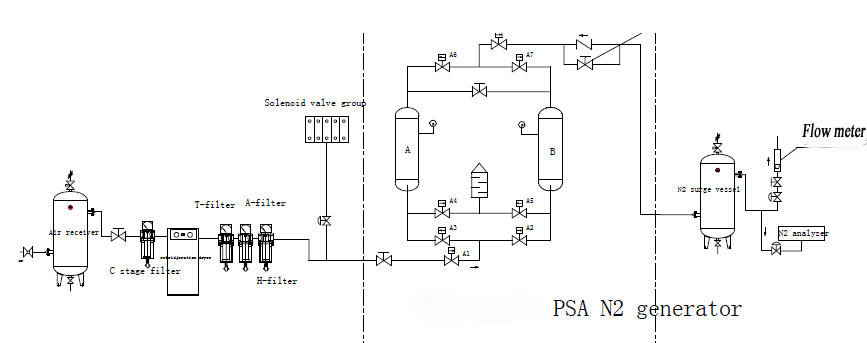

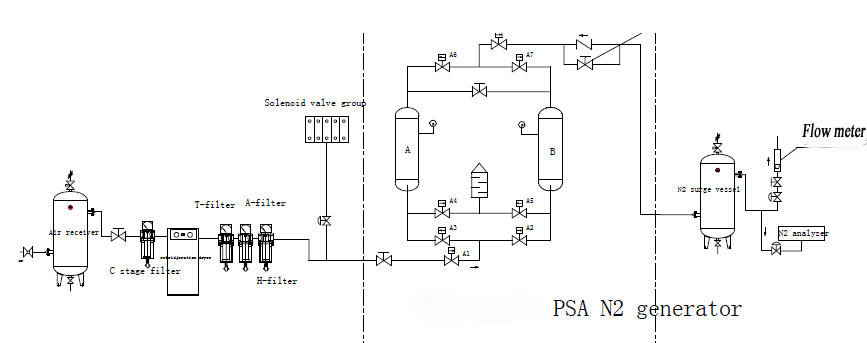

Nitrogen generator system general flow:  Main parameters of our nitrogen generator

Main parameters of our nitrogen generator

Technological Process:

Nitrogen generator system from our company are designed and manufactured based on the technology of Pressure Swing Adsorption(PSA), a mature technology which was developed in Europe in the early 1960s. Ambient air, having being compressed and purified to remove oil, water and dust, enters the adsoption swing adsorping device with two adsorption towers filled with carcon molecular sieve(CMS) to separate nitrogen gas from the compressed air by absorbing the O2,CO2 and water molecules onto the surface of the CMS while under pressure.When the CMS in the adsorption tower(vessel) becomes saturated with waste gases, the pressure is released and the waste gas is vented through the exhause.The second CMS vessel then begins to make nitrogen, while the first on is regeneration.The cycle usually lasts for about 120 seconds.As the production process is more or less a batch operation, nitrogen storage tank is required to buffer the nitrogen product to ensure the continuous flow through the pipeline to the customer's using point. Nitrogen generation from the PSA sytem usually takes place at a pressure ranging from 75psig to 145psig. Nitrogen Generation Advantages

The gas seperation of PSA takes such advantages as different gas has different adsorbing capacity in the CMS under different pressure to separate gases. PSA nitrogen generators are designed based on the PSA theory. They possess the properties of simple technology, low space requirement, quick start up, simple maintenance&operation, good applicability, high automation, low operation cost, low investment, etc.

1) convenient and efficient to generate nitrogen: Advance technology, special gas flow distributor to make the gas distribute more well-distributed, high efficient use of CMS, qualified nitrogen can be offered within 15 to 30 minutes.

2) Convenient use: The equipment structure is compact, low space coverage and no need of construction investment, low investment, the only thing to do is to connect power to generate nitrogen.

3) More economical than other ways of nitrogen supply: PSA technology is a simple way to generate nitrogen. It takes air as source, and the only energy consumption is only electricity consumption. So it has the advantages of low operation cost, low energy consumption and high efficiency.

4) Electromechanical integrated design to realize automatic operation: Imported PLC control the full automation, the flow rate, pressure and purity of nitrogen can be regulated and displayed consecutively; No personnel is needed to be on duty.

Enhancement:To ensure the better quality and longer service life, the main parts such as CMS and PLC, we use world famous brand Japan Takeda and MITSUBISHI, for valves, we use Germany Burkert solenoid valves and pneumatic valves.

Delivery Details:

Packaging details: Standard export packaging

Delivery details: Within 60-90days after receipt of the deposit FAQ What is the service life of Carbon molecular sieves(CMS) Usually, for normaly use, the life span of the CMS is about 5 to 8 years. What is the cycle time to replace the filter element? Usually, the filter element needs to be replaced for every 6000 hours. In order for us to price and size a nitrogen generation system for our customers, the following 4 are needed you: 1. The required flow of nitrogen 2. The required purity of nitrogen 3. The input pressure of your compressed air supply 4. The pressure of the nitrogen used in your application Whenever you need to generate your own nitrogen at desired purity and capacity,come to us, we can handle everything for you, from the air intake to the installation and the after sale services.

Applications of PSA nitrogen generator Nitrogen is widely used throughout the industries. Plenty of applications can benefit from this kind of on-site gas generation method. General Industry: Nitrogen is used in many metal heat treatment activities like annealing, hardening, sintering. And also for welding, brazing and soldering. Plastic Injection Molding In plastic injection molding nitrogen is often used as the assist gas that prevents oxidation of the plastic that leaves the mold with a clean surface finish. Nitrogen is also injected with the plastic creating air channels which results in less plastic needed without cutting the strength. Food and Beverage Packaging Nitrogen is used at different stages in the production, handling and packing of beverages. Because of its inert, colorless and odorless characteristics, it is used to displace or replace the air to reduce the risk of deterioration of the properties of the end product. Nitrogen generator production line:

Applications of PSA nitrogen generator Nitrogen is widely used throughout the industries. Plenty of applications can benefit from this kind of on-site gas generation method. General Industry: Nitrogen is used in many metal heat treatment activities like annealing, hardening, sintering. And also for welding, brazing and soldering. Plastic Injection Molding In plastic injection molding nitrogen is often used as the assist gas that prevents oxidation of the plastic that leaves the mold with a clean surface finish. Nitrogen is also injected with the plastic creating air channels which results in less plastic needed without cutting the strength. Food and Beverage Packaging Nitrogen is used at different stages in the production, handling and packing of beverages. Because of its inert, colorless and odorless characteristics, it is used to displace or replace the air to reduce the risk of deterioration of the properties of the end product. Nitrogen generator production line:  Nitrogen generator system general flow:

Nitrogen generator system general flow:  Main parameters of our nitrogen generator

Main parameters of our nitrogen generator |

Model | Capacity (Nm³/h) | Feed Gas | Product gas:nitrogen gas | |||||

| Pressure (Mpa) | Dew point (°C) | Residual oil (ppm) | Dew point (°C) | Purity (%) | Pressure (Mpa) | Temperature | ||

XRFD98 |

5-2000 |

0.7-1.0 |

≤-17 |

≤0.003 |

≤-40 | ≥98 |

0.6-0.9 |

Ambient temperature |

XRFD29 | ≥99 | |||||||

XRFD295 | ≥99.5 | |||||||

XRFD39 | ≥99.9 | |||||||

XRFD49 | ≥99.99 | |||||||

Technological Process:

Nitrogen generator system from our company are designed and manufactured based on the technology of Pressure Swing Adsorption(PSA), a mature technology which was developed in Europe in the early 1960s. Ambient air, having being compressed and purified to remove oil, water and dust, enters the adsoption swing adsorping device with two adsorption towers filled with carcon molecular sieve(CMS) to separate nitrogen gas from the compressed air by absorbing the O2,CO2 and water molecules onto the surface of the CMS while under pressure.When the CMS in the adsorption tower(vessel) becomes saturated with waste gases, the pressure is released and the waste gas is vented through the exhause.The second CMS vessel then begins to make nitrogen, while the first on is regeneration.The cycle usually lasts for about 120 seconds.As the production process is more or less a batch operation, nitrogen storage tank is required to buffer the nitrogen product to ensure the continuous flow through the pipeline to the customer's using point. Nitrogen generation from the PSA sytem usually takes place at a pressure ranging from 75psig to 145psig. Nitrogen Generation Advantages

The gas seperation of PSA takes such advantages as different gas has different adsorbing capacity in the CMS under different pressure to separate gases. PSA nitrogen generators are designed based on the PSA theory. They possess the properties of simple technology, low space requirement, quick start up, simple maintenance&operation, good applicability, high automation, low operation cost, low investment, etc.

1) convenient and efficient to generate nitrogen: Advance technology, special gas flow distributor to make the gas distribute more well-distributed, high efficient use of CMS, qualified nitrogen can be offered within 15 to 30 minutes.

2) Convenient use: The equipment structure is compact, low space coverage and no need of construction investment, low investment, the only thing to do is to connect power to generate nitrogen.

3) More economical than other ways of nitrogen supply: PSA technology is a simple way to generate nitrogen. It takes air as source, and the only energy consumption is only electricity consumption. So it has the advantages of low operation cost, low energy consumption and high efficiency.

4) Electromechanical integrated design to realize automatic operation: Imported PLC control the full automation, the flow rate, pressure and purity of nitrogen can be regulated and displayed consecutively; No personnel is needed to be on duty.

Enhancement:To ensure the better quality and longer service life, the main parts such as CMS and PLC, we use world famous brand Japan Takeda and MITSUBISHI, for valves, we use Germany Burkert solenoid valves and pneumatic valves.

Delivery Details:

Packaging details: Standard export packaging

Delivery details: Within 60-90days after receipt of the deposit FAQ What is the service life of Carbon molecular sieves(CMS) Usually, for normaly use, the life span of the CMS is about 5 to 8 years. What is the cycle time to replace the filter element? Usually, the filter element needs to be replaced for every 6000 hours. In order for us to price and size a nitrogen generation system for our customers, the following 4 are needed you: 1. The required flow of nitrogen 2. The required purity of nitrogen 3. The input pressure of your compressed air supply 4. The pressure of the nitrogen used in your application Whenever you need to generate your own nitrogen at desired purity and capacity,come to us, we can handle everything for you, from the air intake to the installation and the after sale services.