CE Approved Hydrogen Purification Equipment by PSA

- Delivery Time:

- 45 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Jiangsu, China (Mainland) |

|---|

Product Description

Product Description

CE Approved-Hydrogen Purification Equipment by PSA Main Technical Specifications:

Gas Treatment: (10-500)Nm3/h

Adsorption Pressure: 0.8Mpa-2.4Mpa

H2 Purity: 99%-99.99%

Dew Point: -60ºC

This H2 purifying device usually take the mixed gas of N2 and H2 (75% H2 and 25%N2) produced from the ammonia cracker as the source gas,then it purify the mixed gas by pressure swing adsorpting technology to get the pure Hydrogen.

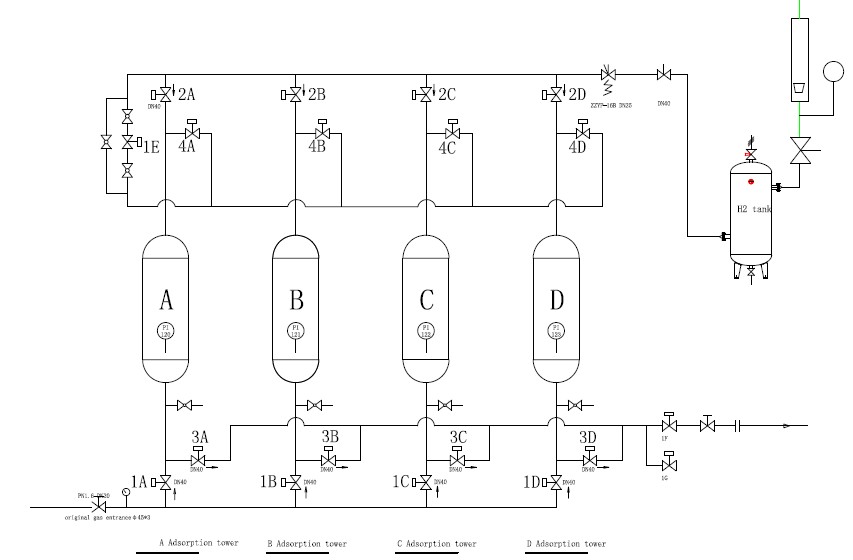

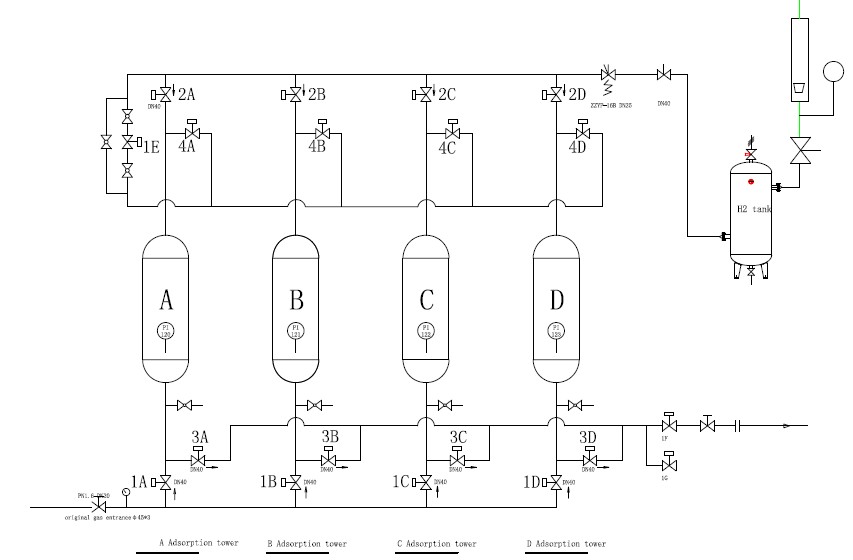

The Principle of H2 purification equipment by PSA

Under certain pressure, take advantage of the adsorption bed composed of many absorbent like activated carbon, silicon dioxide, molecular sieve and alumina, the hydrogen generator selectively adsorbs the impure components in the gas source with hydrogen included such as dissociated methanol, gas released from synthesis ammonia pool, catalytic cracking dry gas in the oil refinery, shift gas, water gas and semi-water gas under pressure, while hydrogen which is difficult to adsorb is put out from the entrance of adsorption tower as the product gas. Therefore, hydrogen purification is realized.

The Flow chart

Delivery Details:

Packaging details: Standard export packaging

Delivery details: Within 60-90days after receipt of the deposit

Gas Treatment: (10-500)Nm3/h

Adsorption Pressure: 0.8Mpa-2.4Mpa

H2 Purity: 99%-99.99%

Dew Point: -60ºC

This H2 purifying device usually take the mixed gas of N2 and H2 (75% H2 and 25%N2) produced from the ammonia cracker as the source gas,then it purify the mixed gas by pressure swing adsorpting technology to get the pure Hydrogen.

The Principle of H2 purification equipment by PSA

Under certain pressure, take advantage of the adsorption bed composed of many absorbent like activated carbon, silicon dioxide, molecular sieve and alumina, the hydrogen generator selectively adsorbs the impure components in the gas source with hydrogen included such as dissociated methanol, gas released from synthesis ammonia pool, catalytic cracking dry gas in the oil refinery, shift gas, water gas and semi-water gas under pressure, while hydrogen which is difficult to adsorb is put out from the entrance of adsorption tower as the product gas. Therefore, hydrogen purification is realized.

The Flow chart

Delivery Details:

Packaging details: Standard export packaging

Delivery details: Within 60-90days after receipt of the deposit