XRM-99.5%-15Nm^3/hr Membrane nitrogen generator

- Delivery Time:

- 45 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Jiangsu, China (Mainland) |

|---|

Product Description

Product Description

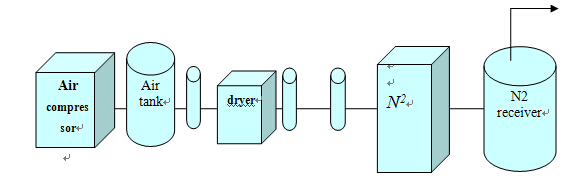

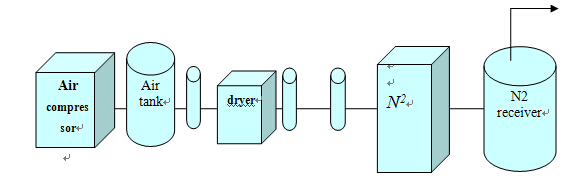

XRM-99.5%-15Nm^3/hr Membrane nitrogen generator  General Flow

General Flow  Technical parameters and Indicators:

Technical parameters and Indicators:

The features of Membrane Nitrogen generation

Membrane air separation technology takes advantage of such phenomenon that some metal membrane or organic membrane filtrate and diffuse certain gas selectively, so as to separate the gas and purity it. Nitrogen generation device by membrane separation is designed based on that principle, as it is with simple technology, low energy consumption, high recovery, quick start-up, module design, low space requirement, easy dilatation, high reliability, less maintenance, high automation, and low running cost. High-pollution resistant property----longer service life Highest production rate---------Highest efficiency Pipe, components and technology with superior quality-------------Comprehensive quality assurance Most thoughtful service---on-call 24hours in 365days Capacity expansion is easy and convenient---expand the nitrogen production rate simply by adding the membrane component Safe and stable----little or no maintenance, no moving parts, so no need to replace the moving parts. Compact structure-----low and light weight, compact structure, space-saving, easy to move. Easy operation-------the whole system is controlled and managed by the computer therefore no personnel are required at site. Quick to produce the gas-----starting up and stop of the machine are easy and convenient. It takes only a few minutes after the machine starts up to supply gas normally. Little pressure loss-------lower energy consumption. Normally, the service life of the Membrane module exceeds 12 years. Purity can be adjusted freely from 95% to 99.5% by adjusting the flow rate. On-site nitrogen system with different specifications can be offered via customers’ different requirement. The Technological process: Ambient air, after compressed to purify to remove the oil, water, dust, enters the separator for separation. First of all, the O2, CO2, and small amount of water vapor will permeate the membrane walls, and then exhaust from the venting mouth on the side of pressure box of the membrane group under atmospheric pressure. Nitrogen in the air permeates the membrane slowly. It flows along fiber holes and vent out from the product gas collecting tube which is on the end of pressure box, and finally enters the product N2 buffer tank. Delivery Details:

Packaging details: Standard export packaging

Delivery details: Within 60-90days after receipt of the deposit

General Flow

General Flow  Technical parameters and Indicators:

Technical parameters and Indicators: |

Model | Capacity (Nm³/h) | Feed Gas | Product gas:nitrogen gas | |||||

| Pressure (Mpa) | Dew point (°C) | Residual oil (ppm) | Dew point (°C) | Purity (%) | Pressure (Mpa) | Temperature | ||

XRM96 |

5-2000 |

0.8-1.3 |

≤-17 |

≤0.003 |

≤-40 | ≥96 |

0.8-0.9 |

Ambient temperature |

XRM97 | ≥97 | |||||||

XRM98 | ≥98 | |||||||

XRM99 | ≥99 | |||||||

XRM99.5 | ≥99.5 | |||||||

Membrane air separation technology takes advantage of such phenomenon that some metal membrane or organic membrane filtrate and diffuse certain gas selectively, so as to separate the gas and purity it. Nitrogen generation device by membrane separation is designed based on that principle, as it is with simple technology, low energy consumption, high recovery, quick start-up, module design, low space requirement, easy dilatation, high reliability, less maintenance, high automation, and low running cost. High-pollution resistant property----longer service life Highest production rate---------Highest efficiency Pipe, components and technology with superior quality-------------Comprehensive quality assurance Most thoughtful service---on-call 24hours in 365days Capacity expansion is easy and convenient---expand the nitrogen production rate simply by adding the membrane component Safe and stable----little or no maintenance, no moving parts, so no need to replace the moving parts. Compact structure-----low and light weight, compact structure, space-saving, easy to move. Easy operation-------the whole system is controlled and managed by the computer therefore no personnel are required at site. Quick to produce the gas-----starting up and stop of the machine are easy and convenient. It takes only a few minutes after the machine starts up to supply gas normally. Little pressure loss-------lower energy consumption. Normally, the service life of the Membrane module exceeds 12 years. Purity can be adjusted freely from 95% to 99.5% by adjusting the flow rate. On-site nitrogen system with different specifications can be offered via customers’ different requirement. The Technological process: Ambient air, after compressed to purify to remove the oil, water, dust, enters the separator for separation. First of all, the O2, CO2, and small amount of water vapor will permeate the membrane walls, and then exhaust from the venting mouth on the side of pressure box of the membrane group under atmospheric pressure. Nitrogen in the air permeates the membrane slowly. It flows along fiber holes and vent out from the product gas collecting tube which is on the end of pressure box, and finally enters the product N2 buffer tank. Delivery Details:

Packaging details: Standard export packaging

Delivery details: Within 60-90days after receipt of the deposit