Stand-up Bag Filling Machine

- Delivery Time:

- 30 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Jiangsu, China (Mainland) |

|---|

Product Description

Product Description

Specifications Stand-up Bag Filling Machine

bag Filling Machine

Vertical Pre-made Filling Machine

Applicable scope:1,Solid Species: candy, peanut, green bean, pistachio, crystal candy, brown sugar, cookie, cake, daily commodities, cooked food, pickles,puffed food etc. 2,Granule Species: grain, refined monosodlum glutamate, granular drug, capsule, seed, chemistiy condiment, granulated sugar, chicken essence, melon seeds, nuts, pesticide, fertilizer, feed etc. 3,Powder species: milk powder, grape sugar, washing powder, chemistry condiment, refined sugar, pesticide, fertilizer etc. 4,Liquid Species & Thick liquid Species: detergent, millet wine, soy sauce, vinegar, fruit juice, drink, tomato sauce, peanut butter, Jam, chili sauce, bean sauce etc. 5,Materials that can pack in bag. Performance characteristics: 1, Mitsubishi PLC, touch screen and MSMMI system ensure the operation convenient and safe. 2, Adopt Mitsubishi VVVF system, can optionally adjust speed in rated range. 3, Auto-detection function: If pouches are not open enough, do not feed materials and sealing that avoid waste materials and economize production cost. 4, Advanced fault detection device: When working air pressure is abnormal or devices (heating pipe etc.) have fault, it will alarm. 5, Horizontal bag-giving model: bags can be loaded more and easy to molding and opening. 6, Some parts adopt imported Engineering Plastics bearing, do not need to oil, reduce the material pollution. 7, Adopt no-oil vacuum generator, avoid production environment pollution. 8, Zipper-bag opening device: specially designed for zipper bags, avoid lura broken problem. 9, Using prefabricate packing bag that have perfect surface and seal, low wastage and high level. 10, Measure up to hygienic standard of food processing industry, all parts that may contact with materials or packing bags are made by stainless steel or other food hygienic standard measuring up materials, ensure the products’ safe and hygienic. 11, Wide packing application: through selecting different quantifier and filler, it can be applied in liquid packing, paste packing, granule packing, powder packing, irregular lump packing etc. 12, Wide suitable scope: it is suitable for prefabricated bags, paper bags made by complex film, PE, PP etc. Technical parameters:

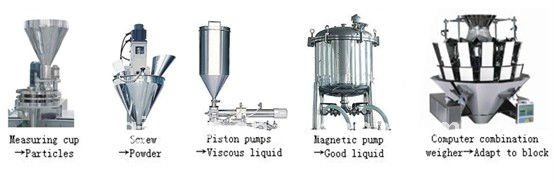

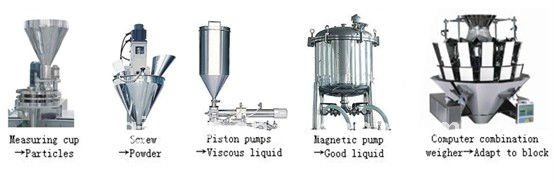

Applicable scope:1,Solid Species: candy, peanut, green bean, pistachio, crystal candy, brown sugar, cookie, cake, daily commodities, cooked food, pickles,puffed food etc. 2,Granule Species: grain, refined monosodlum glutamate, granular drug, capsule, seed, chemistiy condiment, granulated sugar, chicken essence, melon seeds, nuts, pesticide, fertilizer, feed etc. 3,Powder species: milk powder, grape sugar, washing powder, chemistry condiment, refined sugar, pesticide, fertilizer etc. 4,Liquid Species & Thick liquid Species: detergent, millet wine, soy sauce, vinegar, fruit juice, drink, tomato sauce, peanut butter, Jam, chili sauce, bean sauce etc. 5,Materials that can pack in bag. Performance characteristics: 1, Mitsubishi PLC, touch screen and MSMMI system ensure the operation convenient and safe. 2, Adopt Mitsubishi VVVF system, can optionally adjust speed in rated range. 3, Auto-detection function: If pouches are not open enough, do not feed materials and sealing that avoid waste materials and economize production cost. 4, Advanced fault detection device: When working air pressure is abnormal or devices (heating pipe etc.) have fault, it will alarm. 5, Horizontal bag-giving model: bags can be loaded more and easy to molding and opening. 6, Some parts adopt imported Engineering Plastics bearing, do not need to oil, reduce the material pollution. 7, Adopt no-oil vacuum generator, avoid production environment pollution. 8, Zipper-bag opening device: specially designed for zipper bags, avoid lura broken problem. 9, Using prefabricate packing bag that have perfect surface and seal, low wastage and high level. 10, Measure up to hygienic standard of food processing industry, all parts that may contact with materials or packing bags are made by stainless steel or other food hygienic standard measuring up materials, ensure the products’ safe and hygienic. 11, Wide packing application: through selecting different quantifier and filler, it can be applied in liquid packing, paste packing, granule packing, powder packing, irregular lump packing etc. 12, Wide suitable scope: it is suitable for prefabricated bags, paper bags made by complex film, PE, PP etc. Technical parameters:

bag Filling Machine

Vertical Pre-made Filling Machine

Applicable scope:1,Solid Species: candy, peanut, green bean, pistachio, crystal candy, brown sugar, cookie, cake, daily commodities, cooked food, pickles,puffed food etc. 2,Granule Species: grain, refined monosodlum glutamate, granular drug, capsule, seed, chemistiy condiment, granulated sugar, chicken essence, melon seeds, nuts, pesticide, fertilizer, feed etc. 3,Powder species: milk powder, grape sugar, washing powder, chemistry condiment, refined sugar, pesticide, fertilizer etc. 4,Liquid Species & Thick liquid Species: detergent, millet wine, soy sauce, vinegar, fruit juice, drink, tomato sauce, peanut butter, Jam, chili sauce, bean sauce etc. 5,Materials that can pack in bag. Performance characteristics: 1, Mitsubishi PLC, touch screen and MSMMI system ensure the operation convenient and safe. 2, Adopt Mitsubishi VVVF system, can optionally adjust speed in rated range. 3, Auto-detection function: If pouches are not open enough, do not feed materials and sealing that avoid waste materials and economize production cost. 4, Advanced fault detection device: When working air pressure is abnormal or devices (heating pipe etc.) have fault, it will alarm. 5, Horizontal bag-giving model: bags can be loaded more and easy to molding and opening. 6, Some parts adopt imported Engineering Plastics bearing, do not need to oil, reduce the material pollution. 7, Adopt no-oil vacuum generator, avoid production environment pollution. 8, Zipper-bag opening device: specially designed for zipper bags, avoid lura broken problem. 9, Using prefabricate packing bag that have perfect surface and seal, low wastage and high level. 10, Measure up to hygienic standard of food processing industry, all parts that may contact with materials or packing bags are made by stainless steel or other food hygienic standard measuring up materials, ensure the products’ safe and hygienic. 11, Wide packing application: through selecting different quantifier and filler, it can be applied in liquid packing, paste packing, granule packing, powder packing, irregular lump packing etc. 12, Wide suitable scope: it is suitable for prefabricated bags, paper bags made by complex film, PE, PP etc. Technical parameters:

Applicable scope:1,Solid Species: candy, peanut, green bean, pistachio, crystal candy, brown sugar, cookie, cake, daily commodities, cooked food, pickles,puffed food etc. 2,Granule Species: grain, refined monosodlum glutamate, granular drug, capsule, seed, chemistiy condiment, granulated sugar, chicken essence, melon seeds, nuts, pesticide, fertilizer, feed etc. 3,Powder species: milk powder, grape sugar, washing powder, chemistry condiment, refined sugar, pesticide, fertilizer etc. 4,Liquid Species & Thick liquid Species: detergent, millet wine, soy sauce, vinegar, fruit juice, drink, tomato sauce, peanut butter, Jam, chili sauce, bean sauce etc. 5,Materials that can pack in bag. Performance characteristics: 1, Mitsubishi PLC, touch screen and MSMMI system ensure the operation convenient and safe. 2, Adopt Mitsubishi VVVF system, can optionally adjust speed in rated range. 3, Auto-detection function: If pouches are not open enough, do not feed materials and sealing that avoid waste materials and economize production cost. 4, Advanced fault detection device: When working air pressure is abnormal or devices (heating pipe etc.) have fault, it will alarm. 5, Horizontal bag-giving model: bags can be loaded more and easy to molding and opening. 6, Some parts adopt imported Engineering Plastics bearing, do not need to oil, reduce the material pollution. 7, Adopt no-oil vacuum generator, avoid production environment pollution. 8, Zipper-bag opening device: specially designed for zipper bags, avoid lura broken problem. 9, Using prefabricate packing bag that have perfect surface and seal, low wastage and high level. 10, Measure up to hygienic standard of food processing industry, all parts that may contact with materials or packing bags are made by stainless steel or other food hygienic standard measuring up materials, ensure the products’ safe and hygienic. 11, Wide packing application: through selecting different quantifier and filler, it can be applied in liquid packing, paste packing, granule packing, powder packing, irregular lump packing etc. 12, Wide suitable scope: it is suitable for prefabricated bags, paper bags made by complex film, PE, PP etc. Technical parameters: Items / Model | JX6-200 | JX8-250 |

Min. Pouch Size | 90mm(W)x90mm(L) | |

Max. Pouch Size | 200mm(W)x300mm(L) | 250mm(W)x300mm(L) |

Filling Volume | ≤1000ml | ≤1200ml |

Working position of machine | Six-working station | Eight-working station |

Capacity | ≤45 sachet/min(the speed by packaging different and filling weight ) | |

Pouch Format | Flat pouch Stand up pouch zipper pouch Shaped pouch | |

Filling Station | 1 | 2 |

Electrical Consumption | 2kw | 3.5kw |

Electrical Requirement | 380V/220V 3 phase 50Hz/60Hz | |

Operation Pressure | 0.6Mpa | |

Air Consumption | 400NL/min | |

Weight | 1000kg | 1200kg |

Main Machine Size | 1800mm(L)x1500mm(W)x1500mm(H) | 2300mm(L)x1800mm(W)x1650mm(H) |

Related Keywords

Related Keywords