3000W/3500W IP23/IP55 Energy-saving door mounting battery industrial electric cabinet air cooler

- Delivery Time:

- 25 Days

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Jiangsu, China (Mainland) |

|---|

1.Long service life

2.High stability

3.Compact design

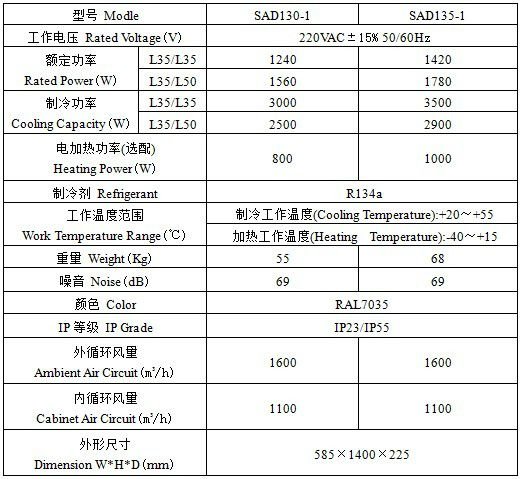

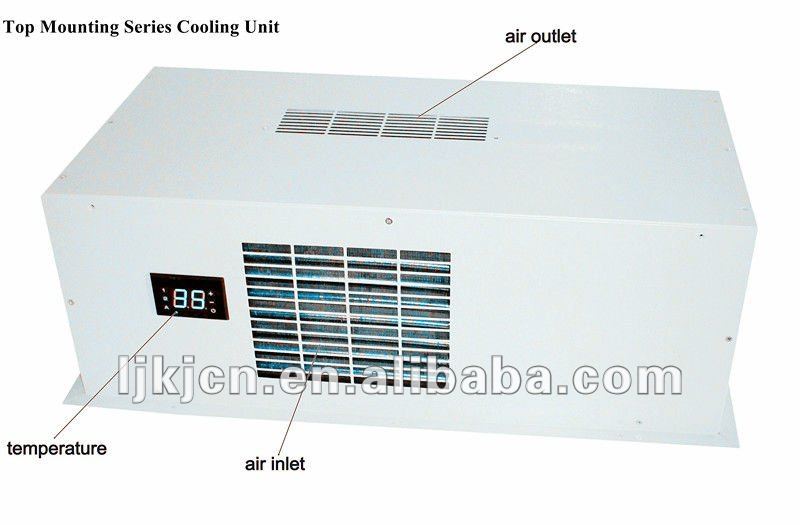

Door Mounting Cabinet Air Conditioner Scope: 1.Widely used in telecommunications,broadcasting,electricity,automation and other industry out-door cabinet,IDC room cooling needs. 2.Applications:electric equipment control box,battery compartment,and telecommunication equipment and other pertinent equipments,enclosed area climate control such as wireless communication cabinet,battery cabinet,industry control cabinet etc. Features: 1. With compact structure and reasonable design, it includes door mounted, side mounted and top mounted series. The cooling capacity ranges from 400W to 3500W. 2. This series of products can be widely used for outdoor communication cabinets, battery cabinets, electric cabinets and industry control cabinets etc. 3. The protective level of internal and external circulation is IP55, which can protect cabinet to avoid moisture, dust, water and also be installed inside and outside 4. Can run at high ambient environment 55°C. 5. Digital temperature controller and high precision of temperature control. 6. The main components have CE certifications, which can meet EU RoHS requirements Technique Data Sheet:

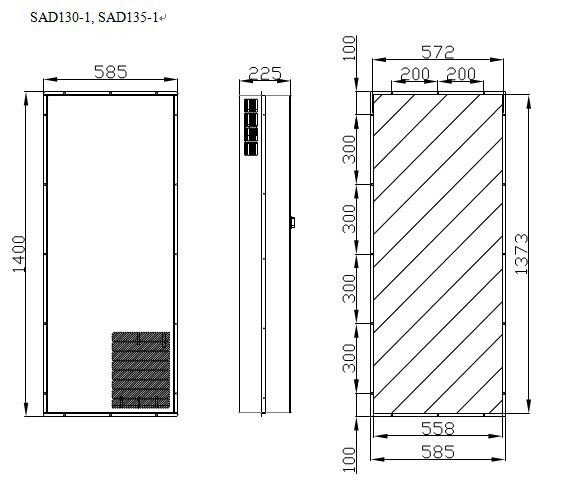

Installation Instruction: 1.Don't use the equipment in the environments with more dust,oil moisture,corrosive or harsh air.Among them shall not exceed 55°C ambient temperature,and not lower than 0°C, humidity should not exceed 95%. 2.Use M6*10 screws fix flange on cabinet. 3.Drain cannot stress,after the installation must ensure smooth condensate drain,handling or moving the equipment,do not upside down,tilt and collision. Installation Picture:

Installation Instruction: 1.Don't use the equipment in the environments with more dust,oil moisture,corrosive or harsh air.Among them shall not exceed 55°C ambient temperature,and not lower than 0°C, humidity should not exceed 95%. 2.Use M6*10 screws fix flange on cabinet. 3.Drain cannot stress,after the installation must ensure smooth condensate drain,handling or moving the equipment,do not upside down,tilt and collision. Installation Picture:

Application:

Application:  Related Products:

Related Products:

Certification:

Certification:

How to Determine Correct Model of Cabinet cooler Key Point---Calculating Heat Load for your Enclosure

How to Determine Correct Model of Cabinet cooler Key Point---Calculating Heat Load for your EnclosureTo determine the correct model for your application, it is first necessary to determine the total heat load to which the control panel is subjected. This total heat load is the combination of two factors — heat dissipated within the enclosure and heat transfer from outside into the enclosure.

Steps of Calculating Btu/hr.:

1. First, determine the approximate watts of heat generated within the enclosure. Watts x 3.41 = Btu/hr.

2. Then, calculate outside heat transfer as follows:

a. Determine the area in square feet exposed to the air, ignoring the top of the cabinet.

b. Determine the temperature differential between maximum surrounding temperature and desired internal temperature. Then, using the Temperature Conversion Table (below), determine the Btu/hr./ft.2 for that differential. Multiplying the cabinet surface area times Btu/hr./ft.2 provides external heat transfer in Btu/hr.

3. Add internal and external heat loads to get total heat load.

Temperature Conversion Table | |

Temperature | Btu/hr/ft.2 |

5 | 1.5 |

10 | 3.3 |

15 | 5.1 |

20 | 7.1 |

25 | 9.1 |

30 | 11.3 |

35 | 13.8 |

40 | 16.2 |

Example: |

Related Keywords