Ultrasonic Vibrating Screen transducer for sieving Calcium Powder system

- Delivery Time:

- 2 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China (Mainland) |

|---|

Product Description

Product Description

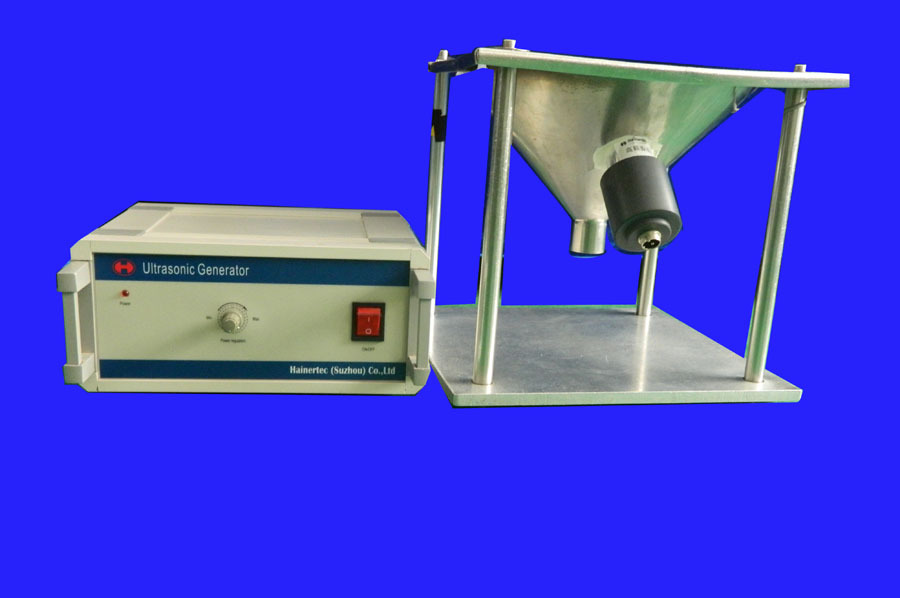

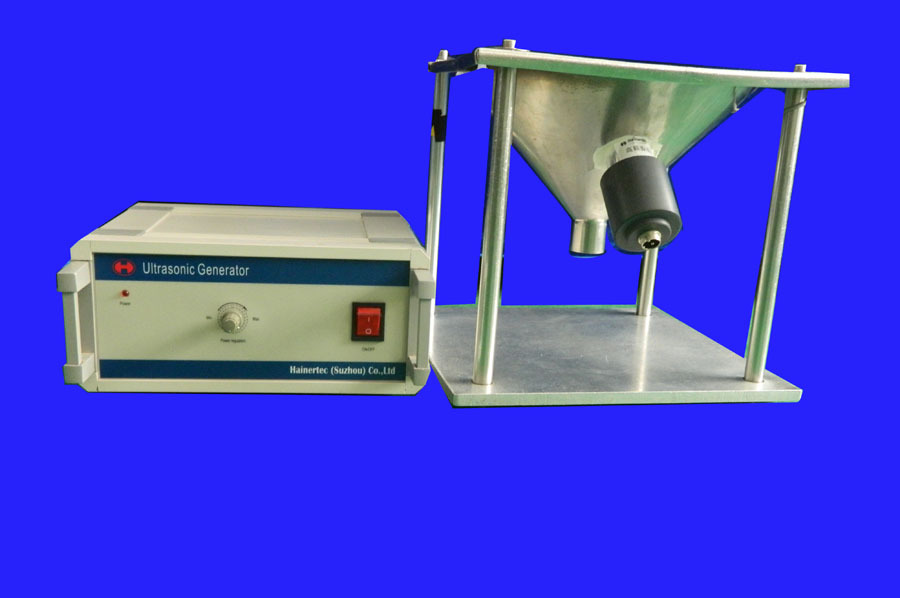

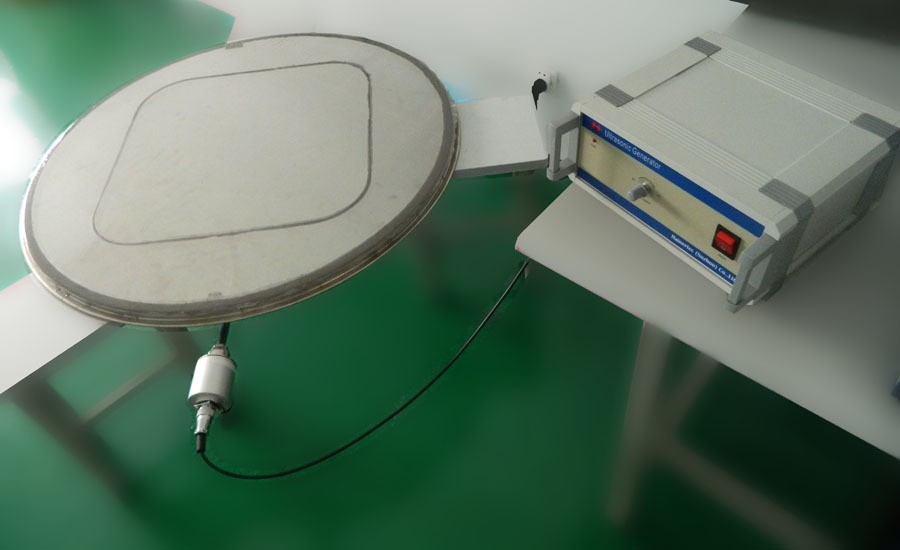

Product Description For ultrasonic virbation screen system , can replace ARTECH ultrasonic transducer Related Products

Detailed Images

Detailed Images

Product Overviews

Product Overviews

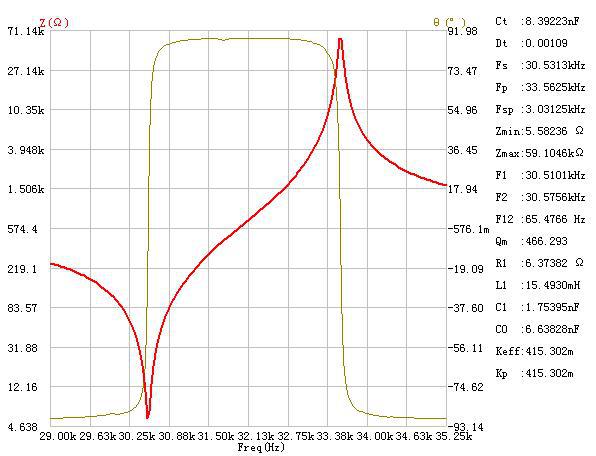

More Technical Information The principle of energy-gathering ultrasonic transducer is same as the welding transducer. It is through exerting pre-stress to offset the swelling stress of piezoelectric ceramics and generate high frequency vibration with large amplitude. While it gathers energy and launch out in the smaller end of transducer, thus the partial acoustic-power rate is very big. So it requires high quality material and fine technique. It belongs to the high-power ultrasonic transducer. The transducer together with the booster and smaller diameter horn formed a vibrating system of partial high power and great oscillation amplitude, so as to realize ultrasonic smashing, extraction, emulsification, metal processing, etc. Energy gathering ultrasonic transducer works in gaps or says work by pulse, it belong to high-power transducer. Generally its amount of power is calculated by the instantaneous peak power.

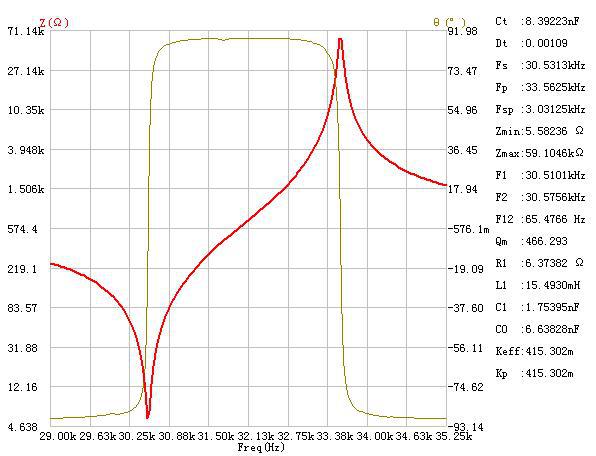

Type | Frequency (KHz) | Capacitance (pF) | Impedance (Ω) | Power (W) | Insulation impedance (2500VDC) |

HNW-8SE-3532(4-4) | 30.5±0.5 | 8300±10% | ≤30Ω | 100 | 100MΩ |

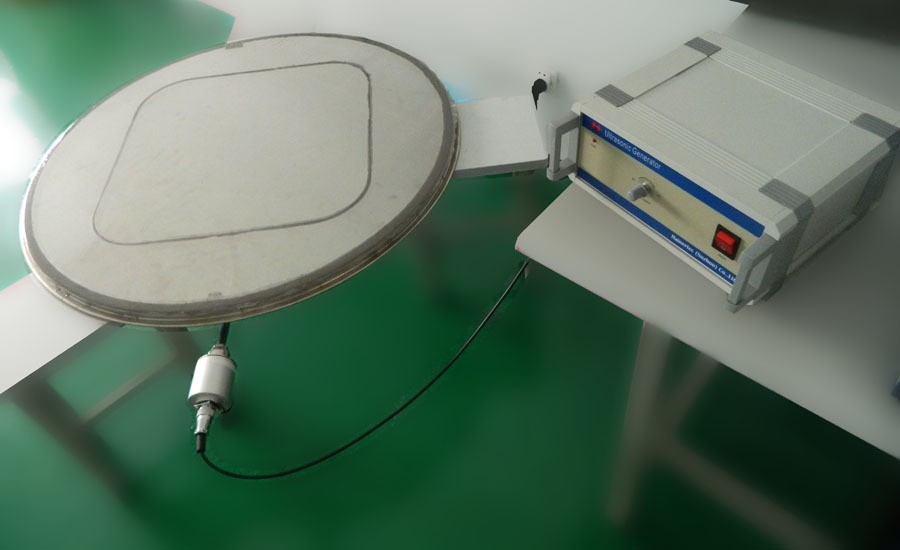

Detailed Images

Detailed Images

Product Overviews

Product Overviews | Model | Resonance frequency | Static capacitance | Resonance Impendance | Power | Size(mm) | Notes |

| (KHz) | (pF) | (Ω) | (W) | D*H | ||

| HNV-8SH-4533 (5*2)-B | 33±2.0 | 6800±10% | ≤10Ω | 80 | Ø65×85 | Bottom vibration series |

| HNV-8SH-3833 (5*2)-B | 33±2.0 | 4800±10% | ≤10Ω | 60 | Ø58×85 | |

| HNV-8SH-3535 (5*2)-B | 35±2.0 | 4500±10% | ≤10Ω | 50 | Ø55×80 | |

| HNV-8SE-4530 (5*2)-S | 31±2.0 | 6800±10% | ≤10Ω | 80 | Ø65×130 | The lateral vibration series |

| HNV-8SE-3833 (5*2)-S | 33±2.0 | 4500±10% | ≤10Ω | 60 | Ø58×130 | |

| HNV-8SE-3535(5*2)-S | 35±2.0 | 4000±10% | ≤10Ω | 50 | Ø55×120 | |

| HNV-8SE-3030(4*4-S | 31±2.0 | 9000±10% | ≤10Ω | 120 | Ø55×120 | |

| HNV-8SE-2535 (4*4)-S | 35±2.0 | 5500±10% | ≤10Ω | 50 | Ø43×160 | Handheld web series |

| HNV-8AE-2535(5*2)-S | 35±2.0 | 3500±10% | ≤10Ω | 30 | Ø42×133 | |

| HNV-8SE-3535(5*2)-S | 35±2.0 | 4000±10% | ≤10Ω | 50 | Ø55×120 | |

| HNV-8SS-1540(2.5*2)-D | 40±2.0 | 1600±10% | ≤10Ω | 15 | Ø28×95 | Points touching net series |

More Technical Information The principle of energy-gathering ultrasonic transducer is same as the welding transducer. It is through exerting pre-stress to offset the swelling stress of piezoelectric ceramics and generate high frequency vibration with large amplitude. While it gathers energy and launch out in the smaller end of transducer, thus the partial acoustic-power rate is very big. So it requires high quality material and fine technique. It belongs to the high-power ultrasonic transducer. The transducer together with the booster and smaller diameter horn formed a vibrating system of partial high power and great oscillation amplitude, so as to realize ultrasonic smashing, extraction, emulsification, metal processing, etc. Energy gathering ultrasonic transducer works in gaps or says work by pulse, it belong to high-power transducer. Generally its amount of power is calculated by the instantaneous peak power.