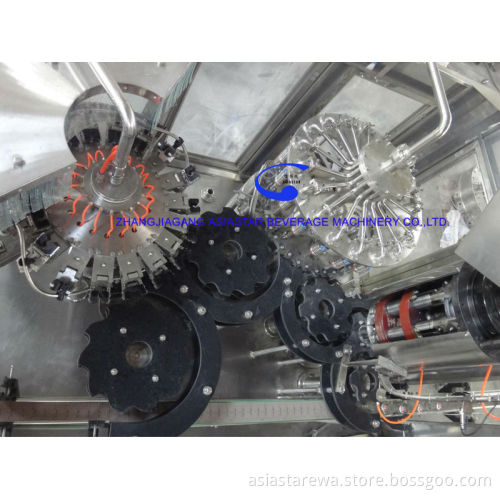

Monoblock 6000BPH Glass bottled juice rinser filler capper

- Delivery Time:

- 45 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Jiangsu, China (Mainland) |

|---|

Product Description

Product Description

Specifications Juice rinser filler capper:

1.Production capacity: 1000-25000BPH

2.Material: SUS304 or SUS316

3.Certification: CE, ISO

4.PLC

Monoblock 6000BPH Glass bottled juice rinser filler capper Juice rinser filler capper Our machine mainly for filling juice drink and tea drink, certainly it also can be used for filling the water, wine, soy sauce, etc. The machine we are designing is an integrated machine, including the rinsing function, filling function, capping function. The whole machine will run automatically, and the filling temperature can be controlled. When change the bottles, only little accessory in the machine need to be changed, and with two workers ,only need 30mins , and then the machine can be ready for filling another kind of bottles. We adopt the micro-pressure filling valve, all the filling operation will be more faster, stable, accurately; The advanced OMRON or MITSUBISHI programmed controller (PLC) is adopted to control the machine to run automatically, while a transducer is used in the bottle -entering chains to adjust speeds and make the operations of moving bottle forward steadily and reliably. Every part in the machine will be inspected strictly before assembly into the machine, to ensure in the following production, the machine can run stably without any problem. The filling category of lower vacuum (Z type machine) is applicable in glass bottles, filling alcohol, soy and such like materials. The aluminum theft proof cap and plastic cap can be adopted

1.Production capacity: 1000-25000BPH

2.Material: SUS304 or SUS316

3.Certification: CE, ISO

4.PLC

Monoblock 6000BPH Glass bottled juice rinser filler capper Juice rinser filler capper Our machine mainly for filling juice drink and tea drink, certainly it also can be used for filling the water, wine, soy sauce, etc. The machine we are designing is an integrated machine, including the rinsing function, filling function, capping function. The whole machine will run automatically, and the filling temperature can be controlled. When change the bottles, only little accessory in the machine need to be changed, and with two workers ,only need 30mins , and then the machine can be ready for filling another kind of bottles. We adopt the micro-pressure filling valve, all the filling operation will be more faster, stable, accurately; The advanced OMRON or MITSUBISHI programmed controller (PLC) is adopted to control the machine to run automatically, while a transducer is used in the bottle -entering chains to adjust speeds and make the operations of moving bottle forward steadily and reliably. Every part in the machine will be inspected strictly before assembly into the machine, to ensure in the following production, the machine can run stably without any problem. The filling category of lower vacuum (Z type machine) is applicable in glass bottles, filling alcohol, soy and such like materials. The aluminum theft proof cap and plastic cap can be adopted

Related Keywords

Related Keywords

You May Also Like

You May Also Like