Automatic 3 in 1 monobloc juice drink bottling machine

- Delivery Time:

- 45 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Jiangsu, China (Mainland) |

|---|

Product Description

Product Description

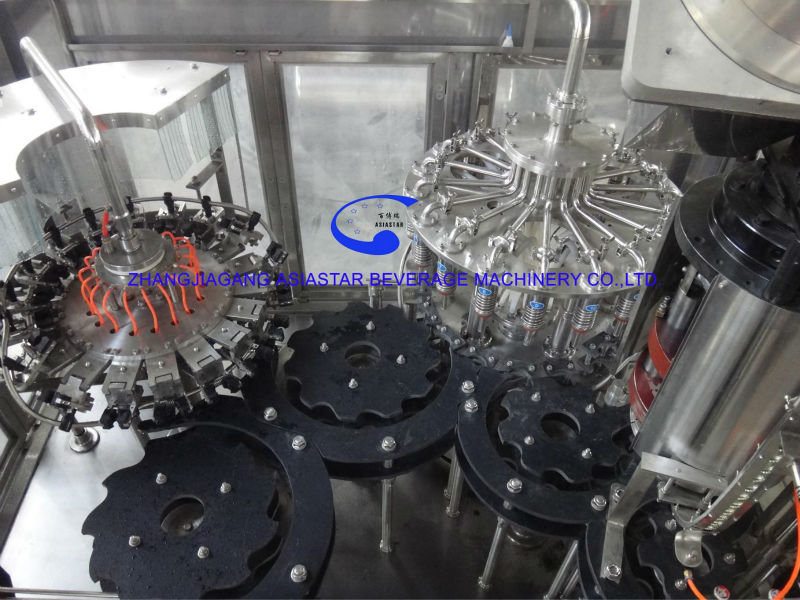

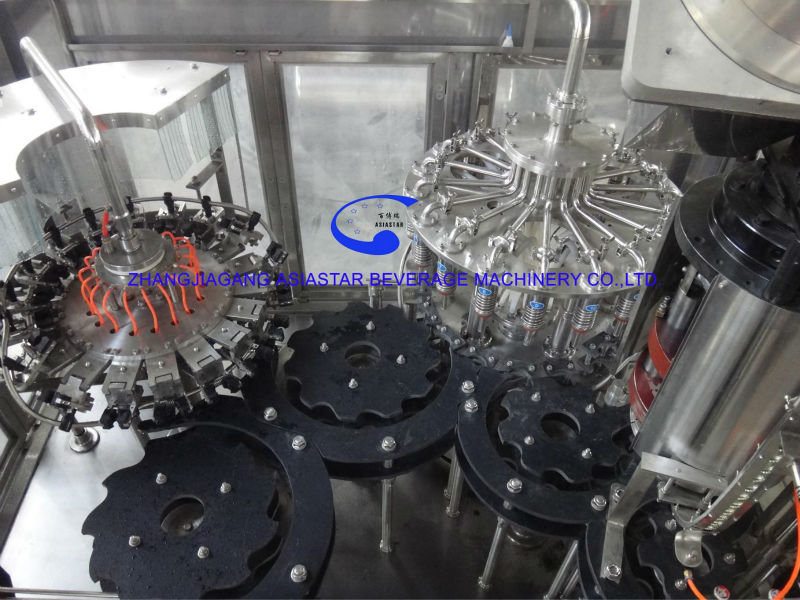

Specifications Juice bottling machine

1.Production capacity:1000-25000BPH

2.PLC control Controlled +Transducer control

3.SUS304 or SUS316

Automatic 3 in 1 monobloc juice drink bottling machine Juice bottling machine 1. Filling products: apple juice, mango juice, orange juice, tea 2. Bottle Volume:250ml-1500ml 3. Cap shape: plastic screw cap, twist off cap, three screw cap 4. Bottle material: PET bottles, glass bottles 5. Producing capacity:1000BPH to 32000BPH Our integrated rinsing filling capping machine designed is especially for filling juice drinks, and tea drinks, with filling degree under 98, and it adopts negative and rotary filling style, max producing speed can arrive 32000 bottles per hour (500ml). Character: a. Specially designed filling valve, with max. beverage flow rate and min. bottle distortion during and after filling; the filling process will be stable, accurate without any spillage b. Directly connected to CIP system, to ensure sanitation for the tank, filling valve, filling tunnel c. All the machine will be controlled by PLC and transducer, the filling speed can be adjustable according to customer requirement d. All the machine will be with the material SUS304 or SUS316, and we can produce the tank in the filling line according to customized requirement

1.Production capacity:1000-25000BPH

2.PLC control Controlled +Transducer control

3.SUS304 or SUS316

Automatic 3 in 1 monobloc juice drink bottling machine Juice bottling machine 1. Filling products: apple juice, mango juice, orange juice, tea 2. Bottle Volume:250ml-1500ml 3. Cap shape: plastic screw cap, twist off cap, three screw cap 4. Bottle material: PET bottles, glass bottles 5. Producing capacity:1000BPH to 32000BPH Our integrated rinsing filling capping machine designed is especially for filling juice drinks, and tea drinks, with filling degree under 98, and it adopts negative and rotary filling style, max producing speed can arrive 32000 bottles per hour (500ml). Character: a. Specially designed filling valve, with max. beverage flow rate and min. bottle distortion during and after filling; the filling process will be stable, accurate without any spillage b. Directly connected to CIP system, to ensure sanitation for the tank, filling valve, filling tunnel c. All the machine will be controlled by PLC and transducer, the filling speed can be adjustable according to customer requirement d. All the machine will be with the material SUS304 or SUS316, and we can produce the tank in the filling line according to customized requirement

Related Keywords

Related Keywords