seamark high pressure pump zirconia ceramic piston

- Delivery Time:

- 20 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Jiangsu, China (Mainland) |

|---|

Product Description

Product Description

Specifications Material: zirconia ceramic

high Density: above 6.0 g/cm3

high mechanical strength.

Good chemical corrosion resistance

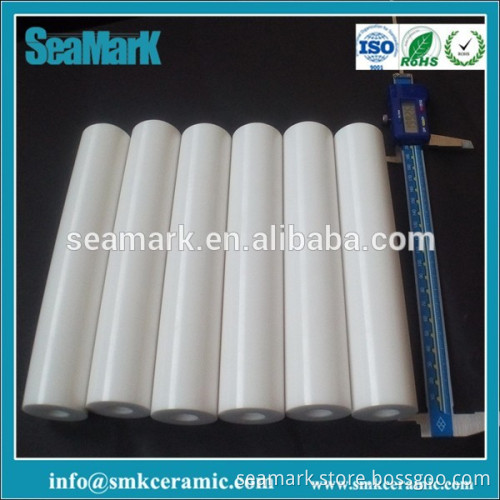

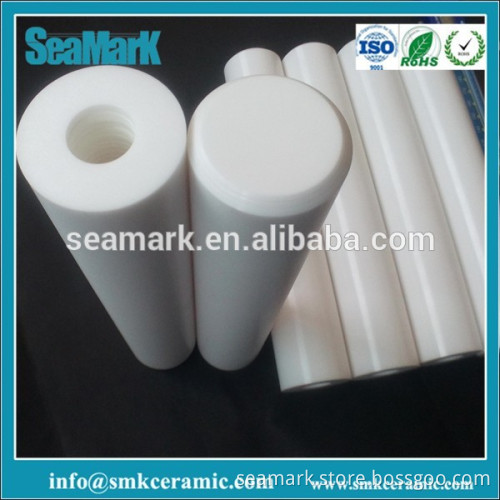

Seamark high pressure pump zirconia ceramic piston Material: zirconia ceramic high Density: above 6.0 g/cm3. Advantage of zirconia ceramic piston: 1,high mechanical strength 2,high temperature, Max working temperature: 1100C. 3,good electrical insulation 4,Good chemical corrosion resistance under high temperature. 5,Excellent wear and abrasion resistance 6,Very hardness and Excellent thermal shock Our normal zirconia ceramic piston OD diameter can reached 400mm, the zirconia ceramic piston normal length within 100mm. but we also can provide 1000mm length ceramic rods.

Property of Zirconia ceramic material. Zirconium Oxide material has the advantage of high toughness and high bending strength, good thermal expansion coefficient, high impact resistant, its superior performance close to the advantages of steel. Zirconium Oxide widely used in mechanical seal and ball mill medium, cutting tools, ceramic bearing, automobile engine parts, paper machine dehydration equipment, etc. The wear resistance of zirconia ceramics is 15 times the size of alumina ceramic, zirconia ceramic friction coefficient is only half of the alumina ceramic, and alumina ceramic friction coefficient is very low. Zirconium Oxide ceramics form Method including: dry press forming, isostatic pressing molding, grouting, hot die-casting molding, cast molding, injection molding, plastic extrusion, colloidal forming of solidification etc. The most widely used form methods are injection molding and dry pressing. More about us. Suzhou Seamark Fine Ceramics Co.,Ltd specialize in researching, developing and providing customized fine ceramic solution. We develop, manufacture and supply precision ceramic products which required hard wearing, lightweight, high temperature, with excellent chemical resistance, good thermal shock and offer enhanced electrical and thermal insulation properties. The main material in Seamark including Aluminium Oxide (Al2O3), Zirconium Oxide (ZrO2), Silicone Carbide (SSiC, RBSiC), metalized ceramics etc.

Property of Zirconia ceramic material. Zirconium Oxide material has the advantage of high toughness and high bending strength, good thermal expansion coefficient, high impact resistant, its superior performance close to the advantages of steel. Zirconium Oxide widely used in mechanical seal and ball mill medium, cutting tools, ceramic bearing, automobile engine parts, paper machine dehydration equipment, etc. The wear resistance of zirconia ceramics is 15 times the size of alumina ceramic, zirconia ceramic friction coefficient is only half of the alumina ceramic, and alumina ceramic friction coefficient is very low. Zirconium Oxide ceramics form Method including: dry press forming, isostatic pressing molding, grouting, hot die-casting molding, cast molding, injection molding, plastic extrusion, colloidal forming of solidification etc. The most widely used form methods are injection molding and dry pressing. More about us. Suzhou Seamark Fine Ceramics Co.,Ltd specialize in researching, developing and providing customized fine ceramic solution. We develop, manufacture and supply precision ceramic products which required hard wearing, lightweight, high temperature, with excellent chemical resistance, good thermal shock and offer enhanced electrical and thermal insulation properties. The main material in Seamark including Aluminium Oxide (Al2O3), Zirconium Oxide (ZrO2), Silicone Carbide (SSiC, RBSiC), metalized ceramics etc.

Service Offer: 1.Drawing We can translate your original drawing: make manufacturing procedure, offer best suggestions on the design. 2.Quality We have full set quality control system to guarantee best product quality. Depends on the products, we make different item testing plan, different manufacturing procedure etc. 3.Inspection We have Professional inspectors. All of them are qualified. Our contacts: Ms.Linda Huang Tel: +86 512 66255075 Fax: +86 512 66255030 Mob: +86 18550512237 www.smkceramic.com

high Density: above 6.0 g/cm3

high mechanical strength.

Good chemical corrosion resistance

Seamark high pressure pump zirconia ceramic piston Material: zirconia ceramic high Density: above 6.0 g/cm3. Advantage of zirconia ceramic piston: 1,high mechanical strength 2,high temperature, Max working temperature: 1100C. 3,good electrical insulation 4,Good chemical corrosion resistance under high temperature. 5,Excellent wear and abrasion resistance 6,Very hardness and Excellent thermal shock Our normal zirconia ceramic piston OD diameter can reached 400mm, the zirconia ceramic piston normal length within 100mm. but we also can provide 1000mm length ceramic rods.

|

Property | Density | g/cm3 | 6 |

Sintering Temperature | ℃ | 1600 | |

Weibull Modulus | m | 23 | |

Vickers Hardness | HV0.5 | 1300 | |

Flexural Strength | Mpa | 1000 | |

|

Thermal Performance | Thermal Expansion | X10-6/K | 10 |

Heat Resistance Impact Force | T(℃) | 360 | |

Thermal Conductivity | W/mk | <2 | |

Thermal Shock Resistance | ΔT℃ | 270 | |

Highest Application Temperature | ℃ | 1000 | |

|

Physical Properties

| Compressive Strength | Mpa | 3000 |

Fracture Toughness | Map.m3/2 | 6-8 | |

Modulus Of Elasticity | GPa | 200 | |

Impact Resistance | MPa.m1/2 | 8 | |

|

Electrical Characteristics | Volume Resistivity at 20℃ | Ωcm | >10^12 |

Dielectric breakdown strength | KV/mm | - | |

Dielectric constant | 100MHz(E) | - | |

| 1 MHZ dielectric loss Angle at 20℃ |

tanδ | - |

Property of Zirconia ceramic material. Zirconium Oxide material has the advantage of high toughness and high bending strength, good thermal expansion coefficient, high impact resistant, its superior performance close to the advantages of steel. Zirconium Oxide widely used in mechanical seal and ball mill medium, cutting tools, ceramic bearing, automobile engine parts, paper machine dehydration equipment, etc. The wear resistance of zirconia ceramics is 15 times the size of alumina ceramic, zirconia ceramic friction coefficient is only half of the alumina ceramic, and alumina ceramic friction coefficient is very low. Zirconium Oxide ceramics form Method including: dry press forming, isostatic pressing molding, grouting, hot die-casting molding, cast molding, injection molding, plastic extrusion, colloidal forming of solidification etc. The most widely used form methods are injection molding and dry pressing. More about us. Suzhou Seamark Fine Ceramics Co.,Ltd specialize in researching, developing and providing customized fine ceramic solution. We develop, manufacture and supply precision ceramic products which required hard wearing, lightweight, high temperature, with excellent chemical resistance, good thermal shock and offer enhanced electrical and thermal insulation properties. The main material in Seamark including Aluminium Oxide (Al2O3), Zirconium Oxide (ZrO2), Silicone Carbide (SSiC, RBSiC), metalized ceramics etc.

Property of Zirconia ceramic material. Zirconium Oxide material has the advantage of high toughness and high bending strength, good thermal expansion coefficient, high impact resistant, its superior performance close to the advantages of steel. Zirconium Oxide widely used in mechanical seal and ball mill medium, cutting tools, ceramic bearing, automobile engine parts, paper machine dehydration equipment, etc. The wear resistance of zirconia ceramics is 15 times the size of alumina ceramic, zirconia ceramic friction coefficient is only half of the alumina ceramic, and alumina ceramic friction coefficient is very low. Zirconium Oxide ceramics form Method including: dry press forming, isostatic pressing molding, grouting, hot die-casting molding, cast molding, injection molding, plastic extrusion, colloidal forming of solidification etc. The most widely used form methods are injection molding and dry pressing. More about us. Suzhou Seamark Fine Ceramics Co.,Ltd specialize in researching, developing and providing customized fine ceramic solution. We develop, manufacture and supply precision ceramic products which required hard wearing, lightweight, high temperature, with excellent chemical resistance, good thermal shock and offer enhanced electrical and thermal insulation properties. The main material in Seamark including Aluminium Oxide (Al2O3), Zirconium Oxide (ZrO2), Silicone Carbide (SSiC, RBSiC), metalized ceramics etc. | Material | ZrO2 Ceramic |

| Application area | sand mill,filling machine |

| Health care,blood dialysis machine, pump, ultrafiltration pump | |

| High pressure washing machine | |

| Car industrial | |

| Oil well drilling equipment, mud pump etc | |

| Electronic insulator | |

| Household items such as ceramic knives, ceramic haircut knife | |

| Processing Capacity | |

| Dimension Range | |

| Out Diameter | 1---100 |

| Inner Diameter | 0.1---80 |

| Length | 0.5---400 |

| Position Accurancy | |

| Perpendicularity | 0.01 |

| Concentrictiy | 0.01 |

| Roundness | 0.005 |

| Straightness | 0.005 |

| Parallelism | 0.01 |

| Planeness | 0.005 |

| Roughness (Ra) | 0.05 |

| Fit Clearance | 0.005 |

| 1.Material : | Zirconia ceramic/alumina ceramic/ silicon carbide ceramic/ silicon nitride ceramic |

| 2.Color: | white/blue zirconia |

| 3.Size: | Customized |

| 4.Logo: | Customized logo |

| 5.Promotional Gifts MOQ: | Small MOQ,500PCS |

| 6.Samples Time: | 7-25days-depends on your drawing. |

| 7.OEM Accepted | Yes |

| 8.Certification available: | Yes-SGS |

| 9.Packing Details: | Cartons or wooden outside, bubble package inside. |

| 10.Production Capacity: | 1000,000pcs Per month. |

| 11.Payment Term: | L/C,T/T,WESTERN UNION |

Related Keywords

Related Keywords