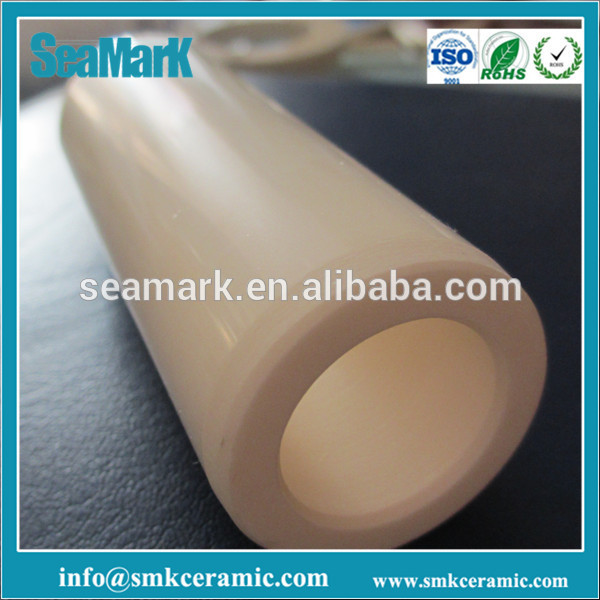

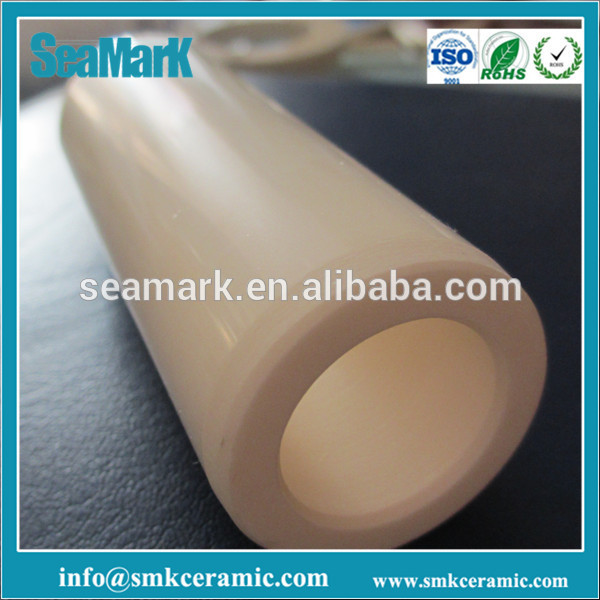

Custom industrial alumina ceramic sleeve

- Delivery Time:

- 20 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Jiangsu, China (Mainland) |

|---|

Product Description

Product Description

Specifications Material: Alumina ceramic

high Density: above 3.9 g/cm3

high mechanical strength.

Good chemical corrosion resistance

Custom industrial alumina ceramic sleeve Material: 99% Alumina ceramic high Density: above 3.9 g/cm3. Advantage of industrial alumina ceramic sleeve. 1.Aluminum Oxide offers good thermal conductivity 2.High temperature capabilities 3.Wear-resistant, very hard 4.High strength and stiffness 5.Resistant to strong acid & alkali 6.Excellent dielectric properties from DC to GHz frequencies Alumina ceramic is the most widely used advanced ceramic material. It has the advantage of good insulation good chemical corrosion resistance and melting properties, small thermal expansion coefficient, mechanical strength, good thermal conductivity characteristics. Industrial Alumina ceramics sleeve is mainly used in biological ceramic, wear resistant materials such as ceramic ball and rod, mechanical parts, such as sealing ring, ceramic valve, high temperature device, such as high temperature liquid delivery pipe, electronic devices such as high voltage switch tube shell insulation material and so on.

More about Seamark. Suzhou Seamark Fine Ceramics Co.,Ltd specialize in researching, developing and providing customized fine ceramic solution. We develop, manufacture and supply precision ceramic products which required hard wearing, lightweight, high temperature, with excellent chemical resistance, good thermal shock and offer enhanced electrical and thermal insulation properties. The main material in Seamark including Aluminium Oxide (Al2O3), Zirconium Oxide (ZrO2), Silicone Carbide (SSiC, RBSiC), metalized ceramics material etc. the main products including industrial ceramic sleeve,ceramic rod, ceramic bushing ,ceramic ring ,ceramic plunger ,ceramic gasket, ceramic sheet etc.

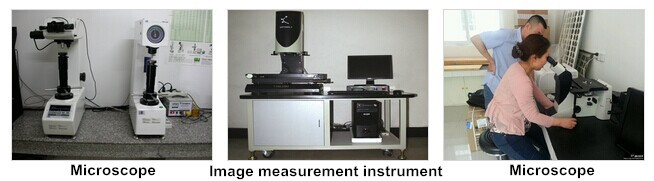

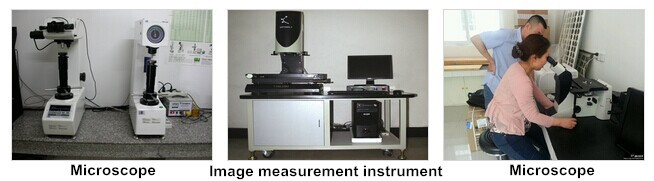

Choose Seamark Ceramic, we are now able to offer following services: 1. Before sales service: we will reply all your questions or inquiry in time, if you need some suggestion on your project, it will be our pleasure to do it. 2. In contract: our strict quality control is performed in every step of producing; we pay attention on every detail to ensure you are satisfied with our products and service. 3. After sales service: any questions, please let us know by email or phone, we will help you to deal with those problems We can supply the products according to customer's drawings, samples and performance requirement. If you need any further information, please do not hesitate to contact us .or you can visit our website.

high Density: above 3.9 g/cm3

high mechanical strength.

Good chemical corrosion resistance

Custom industrial alumina ceramic sleeve Material: 99% Alumina ceramic high Density: above 3.9 g/cm3. Advantage of industrial alumina ceramic sleeve. 1.Aluminum Oxide offers good thermal conductivity 2.High temperature capabilities 3.Wear-resistant, very hard 4.High strength and stiffness 5.Resistant to strong acid & alkali 6.Excellent dielectric properties from DC to GHz frequencies Alumina ceramic is the most widely used advanced ceramic material. It has the advantage of good insulation good chemical corrosion resistance and melting properties, small thermal expansion coefficient, mechanical strength, good thermal conductivity characteristics. Industrial Alumina ceramics sleeve is mainly used in biological ceramic, wear resistant materials such as ceramic ball and rod, mechanical parts, such as sealing ring, ceramic valve, high temperature device, such as high temperature liquid delivery pipe, electronic devices such as high voltage switch tube shell insulation material and so on.

Material | —— | AI-920 | AI-950 | AI-990 | AI-997 | AI-999 |

Texture | —— | Al2O3 | Al2O3 | Al2O3 | Al2O3 | Al2O3 |

>92% | >95% | >99% | >99.7% | >99.9% | ||

Density | g/cm³ | 3.45 | 3.50 | 3.75 | 3.90 | 3.92 |

Bending strength | Mpa | 340 | 300 | 330 | 390 | 390 |

Compressive strength | Mpa | 3600 | 3400 | 3800 | 3900 | 3900 |

Elasticity modulus | Gpa | 350 | 350 | 370 | 390 | 390 |

Impact resistance | Mpam½ | 4.2 | 4.0 | 4.4 | 5.2 | 5.5 |

Weibull Modulus | m | 11 | 10 | 10 | 12 | 12 |

Vickers Hardness | HV 0.5 | 1700 | 1800 | 1800 | 2000 | 2000 |

Thermal expansion | 10^-6K^-1 | 5.0-8.3 | 5.0-8.3 | 5.1-8.3 | 5.5-8.4 | 5.5-8.5 |

Thermal Conductivity | W/mk | 18 | 24 | 25 | 28 | 30 |

Thermal shock resistance | °C | 220 | 250 | 250 | 280 | 280 |

Highest Application Temperature | °C | 1500 | 1600 | 1600 | 1700 | 1700 |

More about Seamark. Suzhou Seamark Fine Ceramics Co.,Ltd specialize in researching, developing and providing customized fine ceramic solution. We develop, manufacture and supply precision ceramic products which required hard wearing, lightweight, high temperature, with excellent chemical resistance, good thermal shock and offer enhanced electrical and thermal insulation properties. The main material in Seamark including Aluminium Oxide (Al2O3), Zirconium Oxide (ZrO2), Silicone Carbide (SSiC, RBSiC), metalized ceramics material etc. the main products including industrial ceramic sleeve,ceramic rod, ceramic bushing ,ceramic ring ,ceramic plunger ,ceramic gasket, ceramic sheet etc.

| Material | Alumina Ceramic |

| Application area | sand mill,filling machine |

| Health care,blood dialysis machine, pump, ultrafiltration pump | |

| High pressure washing machine | |

| Car industrial | |

| Oil well drilling equipment, mud pump etc | |

| Electronic insulator | |

| Household items such as ceramic knives, ceramic haircut knife | |

| Processing Capacity | |

| Dimension Range | |

| Out Diameter | 1---100 |

| Inner Diameter | 0.1---80 |

| Length | 0.5---400 |

| Position Accurancy | |

| Perpendicularity | 0.01 |

| Concentrictiy | 0.01 |

| Roundness | 0.005 |

| Straightness | 0.005 |

| Parallelism | 0.01 |

| Planeness | 0.005 |

| Roughness (Ra) | 0.05 |

| Fit Clearance | 0.005 |

| 1.Material : | Alumina ceramic |

| 2.Color: | white/yellow/pink/ black |

| 3.Size: | Customized |

| 4.Logo: | Customized logo |

| 5.Promotional Gifts MOQ: | Small MOQ,500PCS |

| 6.Samples Time: | 7-25days-depends on your drawing. |

| 7.OEM Accepted | Yes |

| 8.Certification available: | Yes-SGS |

| 9.Packing Details: | Cartons or wooden outside, bubble package inside. |

| 10.Production Capacity: | 1000,000pcs Per month. |

| 11.Payment Term: | L/C,T/T,WESTERN UNION |

Related Keywords

Related Keywords