high pressure alumina ceramic plunger/al2o3 ceramic plunger/ seamark

- Delivery Time:

- 20 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Jiangsu, China (Mainland) |

|---|

Product Description

Product Description

Specifications Full technical support

Competitive pricing and payment terms

high mechanical strength.

Good chemical corrosion resistance

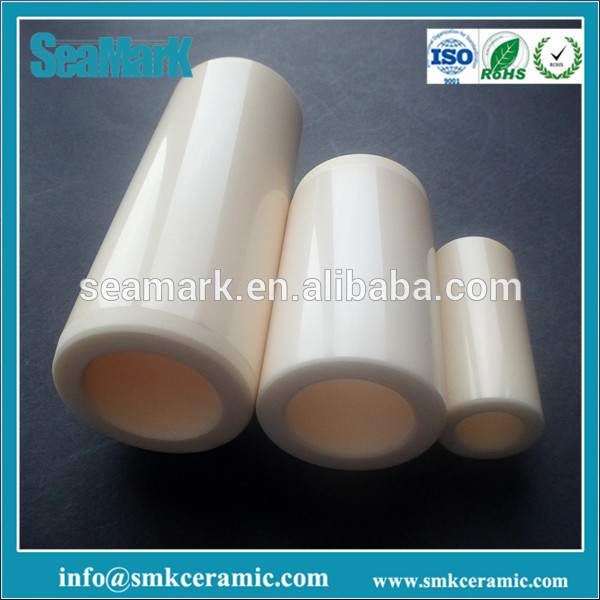

High pressure alumina ceramic plunger/al2o3 ceramic plunger Material: 99% Alumina ceramic Size:OD22*10*40mm Our Advantage

1.High quality and original

2.Large stock and good service

3.Professional supply industrial ceramic

4.Delivery in time

5,Good quality with Competitive price Advantage of 99% alumina ceramic piston. 1.Aluminum Oxide offers good thermal conductivity 2.High temperature capabilities 3.Wear-resistant, very hard 4. Small friction coefficient, low noise, long service life.

Alumina ceramic is the most widely used advanced ceramic material.It mainly used in biological ceramic, wear resistant materials such as ceramic ball and rod, mechanical parts, such as sealing ring, ceramic valve, high temperature device, such as high temperature liquid delivery pipe, electronic devices such as high voltage switch tube shell insulation material and so on. Property of alumina.

Alumina ceramic is the most widely used advanced ceramic material.It mainly used in biological ceramic, wear resistant materials such as ceramic ball and rod, mechanical parts, such as sealing ring, ceramic valve, high temperature device, such as high temperature liquid delivery pipe, electronic devices such as high voltage switch tube shell insulation material and so on. Property of alumina.

More about Seamark. Suzhou Seamark Fine Ceramics Co.,Ltd specialize in researching, developing and providing customized fine ceramic solution. We develop, manufacture and supply precision ceramic products which required hard wearing, lightweight, high temperature, with excellent chemical resistance, good thermal shock and offer enhanced electrical and thermal insulation properties. The main material in Seamark including Aluminium Oxide (Al2O3), Zirconium Oxide (ZrO2), Silicone Carbide (SSiC, RBSiC), metalized ceramics etc.

Packing details: 1. Standard: carton for export 2. Delivery: As per contract delivery on time 3. Shipping: As per client request. We can accept CIF, Door to Door etc. or client authorized agent we supply all necessary assistant. Choose Seamark Ceramic, we are now able to offer following services: 1.Strictly quality control and make sure the precise size. 2.Reasonable price and excellent delivery 3.Professional manufacturer and Reliable ceramic parts provider. 4.Technical support: Experienced designed team and engineer. We will provide day-and-night services and constantly improve service. If you are interested in our products , we can provide the most competitive prices. When you have any request, please feel free to contact us. And any comments or precious advice are welcomed! Looking forward to your kind inquiry. Please give both us and you a chance to gain win-win cooperation!

Competitive pricing and payment terms

high mechanical strength.

Good chemical corrosion resistance

High pressure alumina ceramic plunger/al2o3 ceramic plunger Material: 99% Alumina ceramic Size:OD22*10*40mm Our Advantage

1.High quality and original

2.Large stock and good service

3.Professional supply industrial ceramic

4.Delivery in time

5,Good quality with Competitive price Advantage of 99% alumina ceramic piston. 1.Aluminum Oxide offers good thermal conductivity 2.High temperature capabilities 3.Wear-resistant, very hard 4. Small friction coefficient, low noise, long service life.

Alumina ceramic is the most widely used advanced ceramic material.It mainly used in biological ceramic, wear resistant materials such as ceramic ball and rod, mechanical parts, such as sealing ring, ceramic valve, high temperature device, such as high temperature liquid delivery pipe, electronic devices such as high voltage switch tube shell insulation material and so on. Property of alumina.

Alumina ceramic is the most widely used advanced ceramic material.It mainly used in biological ceramic, wear resistant materials such as ceramic ball and rod, mechanical parts, such as sealing ring, ceramic valve, high temperature device, such as high temperature liquid delivery pipe, electronic devices such as high voltage switch tube shell insulation material and so on. Property of alumina. Material | —— | AI-920 | AI-950 | AI-990 | AI-997 | AI-999 |

Texture | —— | Al2O3 | Al2O3 | Al2O3 | Al2O3 | Al2O3 |

>92% | >95% | >99% | >99.7% | >99.9% | ||

Density | g/cm³ | 3.45 | 3.50 | 3.75 | 3.90 | 3.92 |

Bending strength | Mpa | 340 | 300 | 330 | 390 | 390 |

Compressive strength | Mpa | 3600 | 3400 | 3800 | 3900 | 3900 |

Elasticity modulus | Gpa | 350 | 350 | 370 | 390 | 390 |

Impact resistance | Mpam½ | 4.2 | 4.0 | 4.4 | 5.2 | 5.5 |

Weibull Modulus | m | 11 | 10 | 10 | 12 | 12 |

Vickers Hardness | HV 0.5 | 1700 | 1800 | 1800 | 2000 | 2000 |

Thermal expansion | 10^-6K^-1 | 5.0-8.3 | 5.0-8.3 | 5.1-8.3 | 5.5-8.4 | 5.5-8.5 |

Thermal Conductivity | W/mk | 18 | 24 | 25 | 28 | 30 |

Thermal shock resistance | °C | 220 | 250 | 250 | 280 | 280 |

Highest Application Temperature | °C | 1500 | 1600 | 1600 | 1700 | 1700 |

| Material | Alumina Ceramic |

| Application area | sand mill,filling machine |

| Health care,blood dialysis machine, pump, ultrafiltration pump | |

| High pressure washing machine | |

| Car industrial | |

| Oil well drilling equipment, mud pump etc | |

| Electronic insulator | |

| Household items such as ceramic knives, ceramic haircut knife | |

| Processing Capacity | |

| Dimension Range | |

| Out Diameter | 1---100 |

| Inner Diameter | 0.1---80 |

| Length | 0.5---400 |

| Position Accurancy | |

| Perpendicularity | 0.01 |

| Concentrictiy | 0.01 |

| Roundness | 0.005 |

| Straightness | 0.005 |

| Parallelism | 0.01 |

| Planeness | 0.005 |

| Roughness (Ra) | 0.05 |

| Fit Clearance | 0.005 |

Related Keywords

Related Keywords