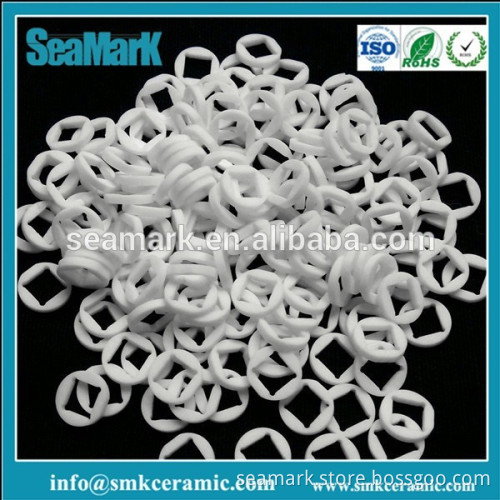

high ceramic insulator /Alumina Electrical Ceramics/ seamark

- Delivery Time:

- 15 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Jiangsu, China (Mainland) |

|---|

Product Description

Product Description

Specifications electrical ceramics

Excellent wear and abrasion resistance.

High dielectric properties

high hardness

high ceramic insulator /Alumina Electrical Ceramics/ seamark Material: 95 or 99 alumina ceramic Density: 3.6 or 3.92 g/cm3 We can supply the products according to customer's drawings, samples and performance requirement.

Electronical Alumina ceramic part with below property: 1.high mechanical strength 2.High temperature, Max working temperature: 1700C. 3.good electrical insulation 4.Good chemical corrosion resistance under high temperature. 5.Excellent wear and abrasion resistance 6.Very hardness and Excellent thermal shock 7.Low dielectric loss, high insulation. Technical Parameter of Alumina.

Electronical Alumina ceramic part with below property: 1.high mechanical strength 2.High temperature, Max working temperature: 1700C. 3.good electrical insulation 4.Good chemical corrosion resistance under high temperature. 5.Excellent wear and abrasion resistance 6.Very hardness and Excellent thermal shock 7.Low dielectric loss, high insulation. Technical Parameter of Alumina.

If you need any further information, please do not hesitate to contact us .or you can visit our website. We will service you all the time.

Excellent wear and abrasion resistance.

High dielectric properties

high hardness

high ceramic insulator /Alumina Electrical Ceramics/ seamark Material: 95 or 99 alumina ceramic Density: 3.6 or 3.92 g/cm3 We can supply the products according to customer's drawings, samples and performance requirement.

Electronical Alumina ceramic part with below property: 1.high mechanical strength 2.High temperature, Max working temperature: 1700C. 3.good electrical insulation 4.Good chemical corrosion resistance under high temperature. 5.Excellent wear and abrasion resistance 6.Very hardness and Excellent thermal shock 7.Low dielectric loss, high insulation. Technical Parameter of Alumina.

Electronical Alumina ceramic part with below property: 1.high mechanical strength 2.High temperature, Max working temperature: 1700C. 3.good electrical insulation 4.Good chemical corrosion resistance under high temperature. 5.Excellent wear and abrasion resistance 6.Very hardness and Excellent thermal shock 7.Low dielectric loss, high insulation. Technical Parameter of Alumina. Material | —— | AI-920 | AI-950 | AI-990 | AI-997 | AI-999 |

Texture | —— | Al2O3 | Al2O3 | Al2O3 | Al2O3 | Al2O3 |

>92% | >95% | >99% | >99.7% | >99.9% | ||

Density | g/cm³ | 3.45 | 3.50 | 3.75 | 3.90 | 3.92 |

Bending strength | Mpa | 340 | 300 | 330 | 390 | 390 |

Compressive strength | Mpa | 3600 | 3400 | 3800 | 3900 | 3900 |

Elasticity modulus | Gpa | 350 | 350 | 370 | 390 | 390 |

Impact resistance | Mpam½ | 4.2 | 4.0 | 4.4 | 5.2 | 5.5 |

Weibull Modulus | m | 11 | 10 | 10 | 12 | 12 |

Vickers Hardness | HV 0.5 | 1700 | 1800 | 1800 | 2000 | 2000 |

Thermal expansion | 10^-6K^-1 | 5.0-8.3 | 5.0-8.3 | 5.1-8.3 | 5.5-8.4 | 5.5-8.5 |

Thermal Conductivity | W/mk | 18 | 24 | 25 | 28 | 30 |

Thermal shock resistance | °C | 220 | 250 | 250 | 280 | 280 |

Highest Application Temperature | °C | 1500 | 1600 | 1600 | 1700 | 1700 |

Related Keywords

Related Keywords