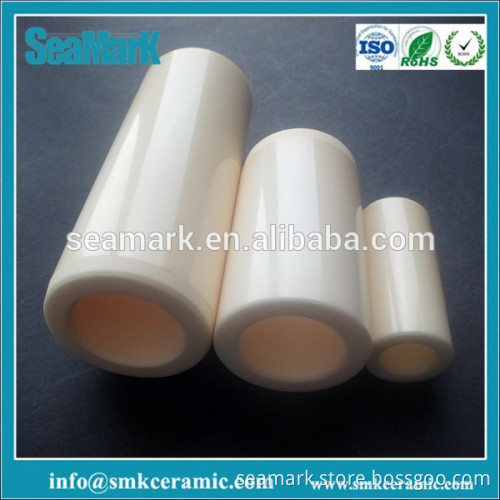

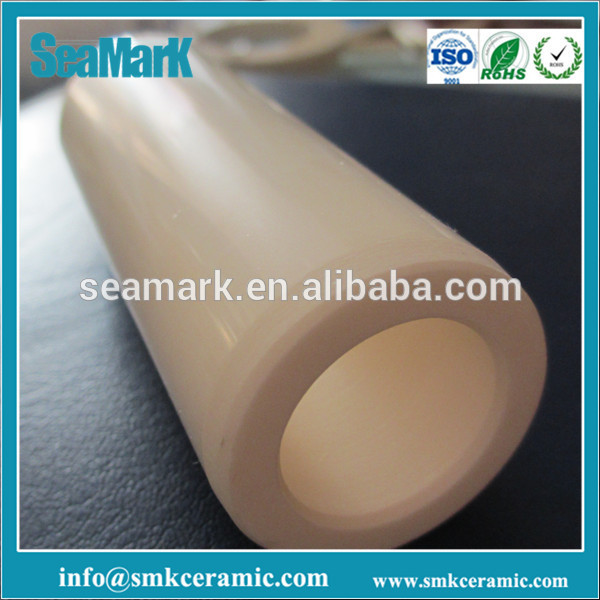

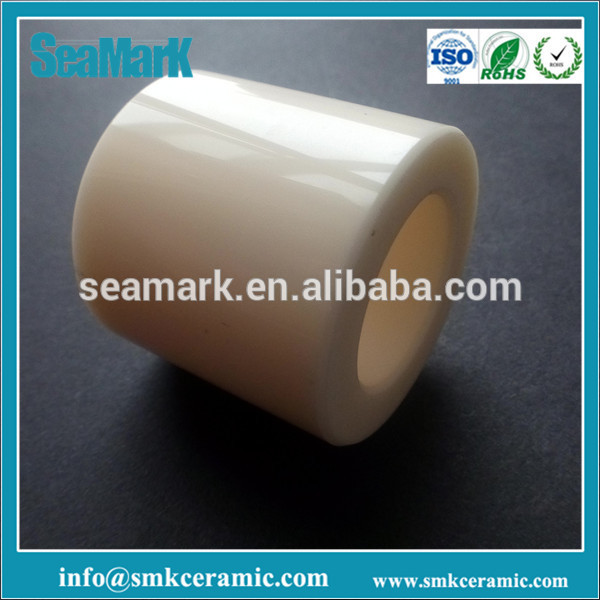

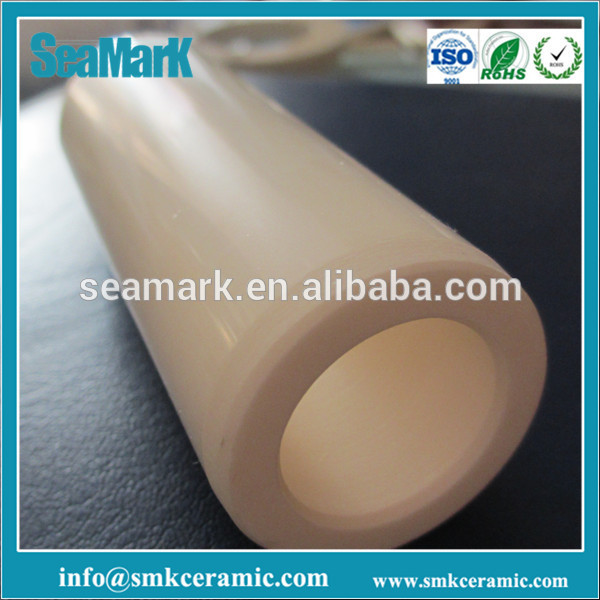

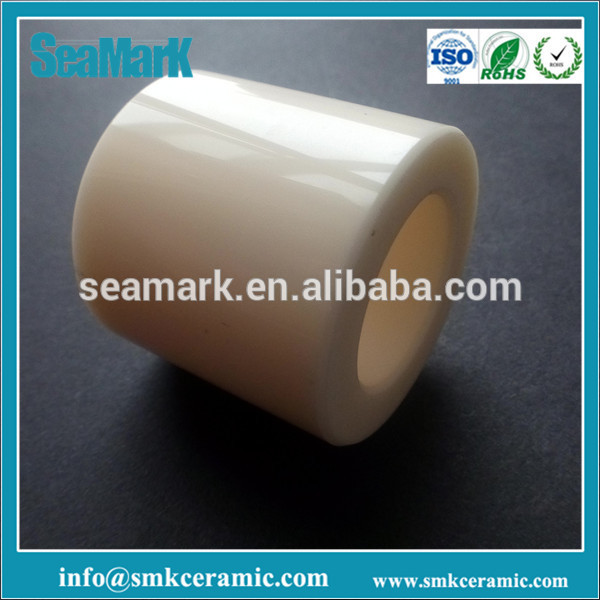

99.5% Alumina ceramic bush

- Delivery Time:

- 20 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Jiangsu, China (Mainland) |

|---|

Product Description

Product Description

99.5% Alumina ceramic bush Material: 99.5% Alumina ceramic/99.5% al2o3 ceramic high Density: above 3.9 g/cm3. Wear resistance and high temperature Advantage of alumina ceramic Bushing. 1.Alumina ceramic bushing offers good thermal conductivity 2.High temperature capabilities 3.Wear-resistant, very hard 4.High strength and stiffness 5.Resistant to strong acid & alkali 6.Excellent dielectric properties from DC to GHz frequencies Alumina ceramic is the most widely used advanced ceramic material. Alumina ceramic bushing is mainly used in biological ceramic, wear resistant materials such as ceramic ball and rod, mechanical parts, such as sealing ring, ceramic valve, high temperature device, such as high temperature liquid delivery pipe, electronic devices such as high voltage switch tube shell insulation material and so on. Data sheet for alumina ceramic.

More about Seamark. Seamark specialize in researching, developing and providing customized fine ceramic solution, our main material including 96% alumina ceramics (Al2O3),99% alumina ceramics,Zirconia ceramics(ZrO2),Silicon carbide(SiC),Silicon Nitride (Si3N4). Whether you are a tooling manufacture or end user, our specialists are available to provide full engineering and technical support throughout the concept, design, and production stages to ensure maximum performance of our material is obtained.

More about Seamark. Seamark specialize in researching, developing and providing customized fine ceramic solution, our main material including 96% alumina ceramics (Al2O3),99% alumina ceramics,Zirconia ceramics(ZrO2),Silicon carbide(SiC),Silicon Nitride (Si3N4). Whether you are a tooling manufacture or end user, our specialists are available to provide full engineering and technical support throughout the concept, design, and production stages to ensure maximum performance of our material is obtained.

Service Offer: 1.Drawing We can translate your original drawing: make manufacturing procedure, offer best suggestions on the design. 2.Quality We have full set quality control system to guarantee best product quality. Depends on the products, we make different item testing plan, different manufacturing procedure etc. 3.Inspection We have Professional inspectors. All of them are qualified. Our contacts: www.smkceramic.com Ms.Linda Huang Tel: +86 512 66255075 Fax: +86 512 66255030 Mob: +86 18550512237 We can supply the products according to customer's drawings, samples and performance requirement. If you need any further information, please do not hesitate to contact us .or you can visit our website.

Material | —— | AI-920 | AI-950 | AI-990 | AI-997 | AI-999 |

Texture | —— | Al2O3 | Al2O3 | Al2O3 | Al2O3 | Al2O3 |

>92% | >95% | >99% | >99.7% | >99.9% | ||

Density | g/cm³ | 3.45 | 3.60 | 3.9 | 3.92 | 3.92 |

Bending strength | Mpa | 300 | 330 | 340 | 390 | 390 |

Compressive strength | Mpa | 3400 | 3600 | 3800 | 3900 | 3900 |

Elasticity modulus | Gpa | 350 | 350 | 370 | 390 | 390 |

Impact resistance | Mpam½ | 4.2 | 4.0 | 4.4 | 5.2 | 5.5 |

Weibull Modulus | m | 11 | 10 | 10 | 12 | 12 |

Vickers Hardness | HV 0.5 | 1700 | 1800 | 1800 | 2000 | 2000 |

Thermal expansion | 10^-6K^-1 | 5.0-8.3 | 5.0-8.3 | 5.1-8.3 | 5.5-8.4 | 5.5-8.5 |

Thermal Conductivity | W/mk | 18 | 24 | 25 | 28 | 30 |

Thermal shock resistance | °C | 220 | 250 | 250 | 280 | 280 |

Highest Application Temperature | °C | 1500 | 1600 | 1600 | 1700 | 1700 |

More about Seamark. Seamark specialize in researching, developing and providing customized fine ceramic solution, our main material including 96% alumina ceramics (Al2O3),99% alumina ceramics,Zirconia ceramics(ZrO2),Silicon carbide(SiC),Silicon Nitride (Si3N4). Whether you are a tooling manufacture or end user, our specialists are available to provide full engineering and technical support throughout the concept, design, and production stages to ensure maximum performance of our material is obtained.

More about Seamark. Seamark specialize in researching, developing and providing customized fine ceramic solution, our main material including 96% alumina ceramics (Al2O3),99% alumina ceramics,Zirconia ceramics(ZrO2),Silicon carbide(SiC),Silicon Nitride (Si3N4). Whether you are a tooling manufacture or end user, our specialists are available to provide full engineering and technical support throughout the concept, design, and production stages to ensure maximum performance of our material is obtained.

| 1.Material : | Alumina ceramic/silicon carbide ceramic/ zirconia ceramic/ silicon nitride ceramic |

| 2.Color: | white/yellow/pink/ black |

| 3.Size: | Customized |

| 4.Logo: | Customized logo |

| 5.Promotional Gifts MOQ: | Small MOQ,500PCS |

| 6.Samples Time: | 7-25days-depends on your drawing. |

| 7.OEM Accepted | Yes |

| 8.Certification available: | Yes-SGS |

| 9.Packing Details: | Cartons or wooden outside, bubble package inside. |

| 10.Production Capacity: | 1000,000pcs Per month. |

| 11.Payment Term: | L/C,T/T,WESTERN UNION |

Related Keywords

Related Keywords