150deg UL fep Insulation high temperature wire

- Delivery Time:

- 3 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

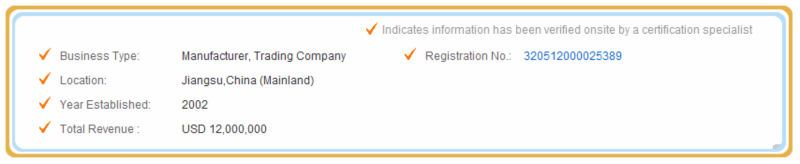

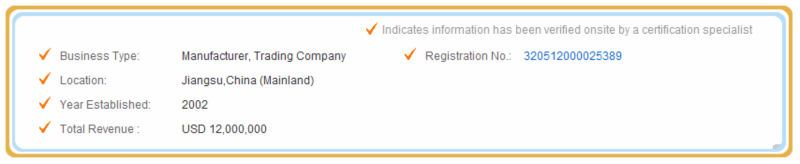

| Place of Origin: | Jiangsu, China (Mainland) |

|---|

Product Description

Product Description

Specifications High Temperature Wire

1.UL approved, RoHS Complian

2 High temperature resistance,anti-acid,anti-oil and antisepsis.

High Temperature Wire Product name : 150deg UL fep Insulation high temperature wire We have cooperated with Apple Company for 8 years! We produce teflon wires 500 Million Meter in 2013 year!!!

High Temperature Wire Product name : 150deg UL fep Insulation high temperature wire We have cooperated with Apple Company for 8 years! We produce teflon wires 500 Million Meter in 2013 year!!!

Customize is Welcome!!! From 42awg to 12awg

Customize is Welcome!!! From 42awg to 12awg

Products :FEP insulated wire temperature 150°C anti-acid,anti-oil,antisepsis , thin ETFE insulated wire Performance better PFA insulated wire temperature 200°C Insulation: with optional color schemes such as transparent, white, black, red, blue, grey, yellow, green, brown, orange and yellow-green etc.

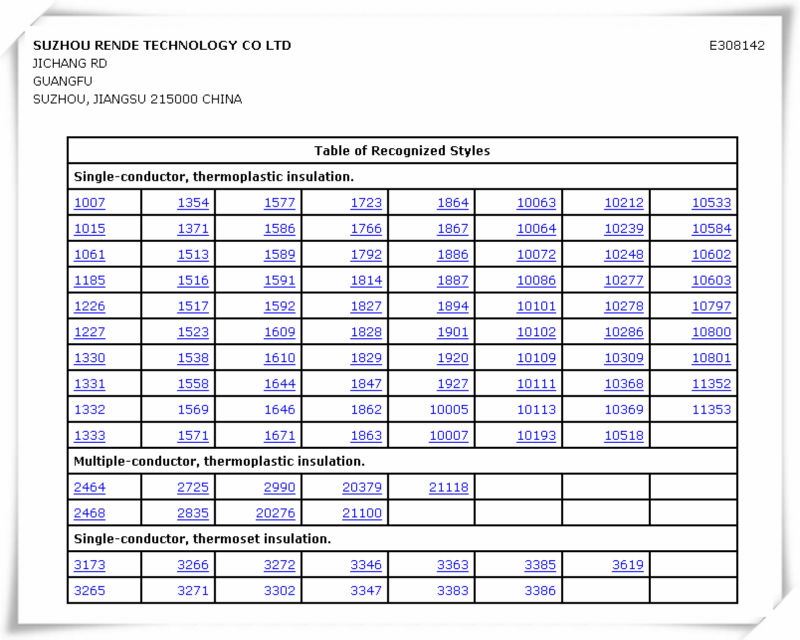

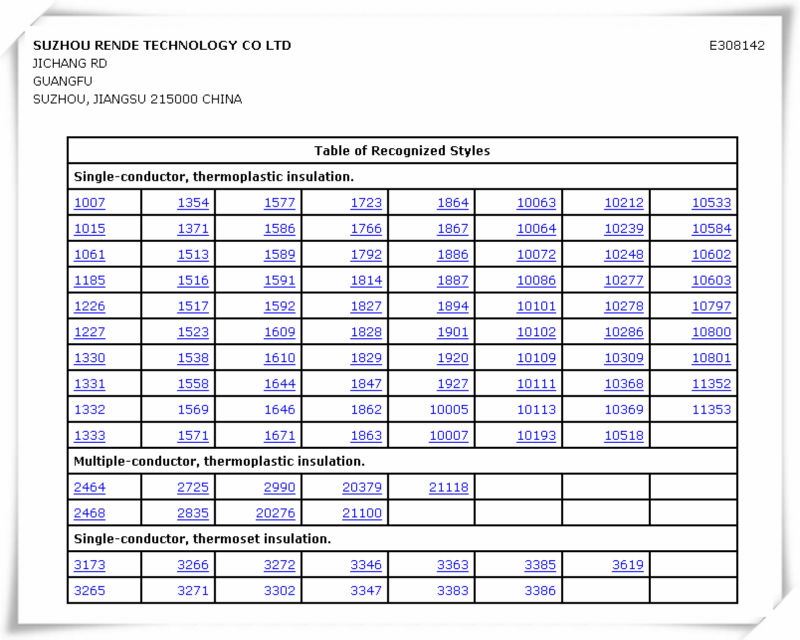

Resistant to acids, alkalis, oils, flame retardant, fire resistance, and low smoke, no halogen. UL approved styles

UL approved styles  Company Description

Company Description

Teflon cable

Teflon cable  Cable Series

Cable Series  Advantage 1.Our company is a Teflon wire leader in domestic, and the supplier of world top 500. 2.Our production technology has four steps with drawing, tinning, stranding and extruding.Blister Copper is processed to Teflon wire with the lowest cost.We are the largest Teflon wire manufacturer with 16 Teflon extruders in domestic. The daily capacity can reach 3200KM. Application

Advantage 1.Our company is a Teflon wire leader in domestic, and the supplier of world top 500. 2.Our production technology has four steps with drawing, tinning, stranding and extruding.Blister Copper is processed to Teflon wire with the lowest cost.We are the largest Teflon wire manufacturer with 16 Teflon extruders in domestic. The daily capacity can reach 3200KM. Application

Widely applied in aviation; metallurgy and petroleum industry as well as applied in other products such as: electronic instrument & device, electrical appliance, lighting equipments, mechanical electrical, leads for transformer & electrical motor. Tester

Tester  Packing

Packing  We can supply wire harness assembly Sample charge: 1.The existing sample is free, only need 1day. 2.According to your design, need 2-3days. need the sample charge. 3.When ensure the PO, We will return back your sample charge. If you want to know more about our factory, please download the BV report in our home page.

We can supply wire harness assembly Sample charge: 1.The existing sample is free, only need 1day. 2.According to your design, need 2-3days. need the sample charge. 3.When ensure the PO, We will return back your sample charge. If you want to know more about our factory, please download the BV report in our home page.

1.UL approved, RoHS Complian

2 High temperature resistance,anti-acid,anti-oil and antisepsis.

High Temperature Wire Product name : 150deg UL fep Insulation high temperature wire We have cooperated with Apple Company for 8 years! We produce teflon wires 500 Million Meter in 2013 year!!!

High Temperature Wire Product name : 150deg UL fep Insulation high temperature wire We have cooperated with Apple Company for 8 years! We produce teflon wires 500 Million Meter in 2013 year!!!

Customize is Welcome!!! From 42awg to 12awg

Customize is Welcome!!! From 42awg to 12awg | AWG | Specification | No. | Stranded Distance(mm) | Stranded OD(mm) | Stranded OD Tolerence(mm) | Singles Diameter Tolerence(mm) | Diameter OD (mm) | |

| AWG42 | TPCA7/0.025 | A | <1.0 | 0.075 | ±0.02 | ±0.002 | 0.18 | |

| AWG40 | TPCA7/0.03 | A | ≤1.3 | 0.090 | ±0.02 | ±0.003 | 0.205 0.31 0.32 | |

| AWG38 | TA7/0.04 | A | 1~2 | 0.120 | ±0.02 | ±0.003 | ||

| AWG36 | TA7/0.05 | A | ≤2.5 | 0.150 | ±0.02 | 0.046~0.053 | 0.28 0.29 | |

| TPCA19/0.03 | A | ≤2.5 | 0.150 | ±0.003 | ||||

| AWG34 | TA7/0.064 | A | 2~3 | 0.192 | ±0.02 | ±0.003 | 0.42 | |

| TA12/0.05 | A | 2~3 | 0.200 | 0.046~0.053 | ||||

| TA19/0.04 | A | 3~4 | 0.200 | ±0.003 | ||||

| B | 2~3 | |||||||

| AWG32 | TA7/0.08 | A | 4~6 | 0.240 | ±0.02 | ±0.003 | 0.36 0.38 | |

| C | 3.5~4 | |||||||

| TA12/0.06 | A | 3~4 | 0.240 | ±0.003 | 0.36 | |||

| TA19/0.05 | A | 3~4 | 0.250 | 0.046~0.053 | 0.36 | |||

| B | <2.5 | |||||||

| AWG30 | TA7/0.1 | A | 5~7 | 0.300 | ±0.02 | 0.096~0.103 | 0.50 0.55 0.60 0.75 | |

| B | 2.5--3.5 | |||||||

| WX | 3~4 | |||||||

| TA12/0.08 | A | 3~5 | 0.320 | ±0.003 | ||||

| TA19/0.06 | A | 3~4 | 0.300 | ±0.003 | ||||

| B | 2~3 | |||||||

| AWG28 | TA7/0.127 | A | 5~7 | 0.381 | ±0.02 | 0.123~0.130 | 0.60 0.62 1.00 | |

| WX | 4~5 | |||||||

| TA19/0.08 | A | 4~6 | 0.400 | ±0.003 | ||||

| TA19/0.08 | B | 3~4 | 0.400 | |||||

| TA49/0.05 | A | 4~6 | 0.400 | 0.046~0.053 | ||||

| AWG27 | TA7/0.14 | A | 4~6 | 0.420 | ±0.02 | 0.136~0.143 | ||

| TA21/0.08 | A | 2~4 | 0.423 | ±0.003 | ||||

| AWG26 | TA7/0.16 | LW | ≤6.5 | 0.70 1.00 | ||||

| TA19/0.10 | A | 4~6 | 0.500 | 0.096~0.103 | ||||

| TA49/0.06 | A | 5~7 | 0.485 | ±0.003 | ||||

| AWG24 | TA7/0.20 | A | 7~9.5 | 0.609 | ±0.03 | 0.193~0.205 | 0.85 0.87 1.05 1.1 | |

| TA7/0.20 | B | 11±2 | ||||||

| TA19/0.127 | A | 8~9 | 0.635 | 0.123~0.130 | ||||

| TA41/0.08 | A | 5~8 | 0.592 | ±0.003 | ||||

| TA11/0.16 | A | 10~14 | 0.613 | ±0.005 | ||||

| AWG23 | TA21/0.127 | A | 9~11 | 0.672 | ±0.03 | 0.123~0.130 | 0.88 | |

| AWG22 | TA7/0.254 | A | ≤14.5 | 0.762 | ±0.03 | ±0.008 | 1.02 | |

| TA19/0.16 | A | 10~13 | 0.800 | ±0.005 | ||||

| AWG21 | TA19/0.18 | A | 13~17 | 0.900 | ±0.03 | ±0.005 | ||

| AWG20 | TA7/0.32 | A | 17~21 | 0.960 | ±0.03 | 0.310~0.328 | ||

| TA41/0.127 | A | 14~18 | 0.939 | 0.123~0.130 | ||||

| AWG18 | TA16/0.254 | A | 9~13 | 1.173 | ±0.03 | 0.250~0.262 | 1.57 | |

| TA19/0.254 | A | 12~14 | 1.270 | ±0.008 | ||||

| TA49/0.16 | A | 18~22 | 1.294 | 0.158~0.165 | ||||

| TA65/0.127 | A | 18~22 | 1.183 | 0.123~0.130 | ||||

| AWG16 | TA19/0.30 | A | 19~21 | 1.500 | ±0.05 | ±0.008 | 1.8 | |

Resistant to acids, alkalis, oils, flame retardant, fire resistance, and low smoke, no halogen.

UL approved styles

UL approved styles  Company Description

Company Description

Teflon cable

Teflon cable  Cable Series

Cable Series  Advantage 1.Our company is a Teflon wire leader in domestic, and the supplier of world top 500. 2.Our production technology has four steps with drawing, tinning, stranding and extruding.Blister Copper is processed to Teflon wire with the lowest cost.We are the largest Teflon wire manufacturer with 16 Teflon extruders in domestic. The daily capacity can reach 3200KM. Application

Advantage 1.Our company is a Teflon wire leader in domestic, and the supplier of world top 500. 2.Our production technology has four steps with drawing, tinning, stranding and extruding.Blister Copper is processed to Teflon wire with the lowest cost.We are the largest Teflon wire manufacturer with 16 Teflon extruders in domestic. The daily capacity can reach 3200KM. Application Widely applied in aviation; metallurgy and petroleum industry as well as applied in other products such as: electronic instrument & device, electrical appliance, lighting equipments, mechanical electrical, leads for transformer & electrical motor.

Tester

Tester  Packing

Packing  We can supply wire harness assembly Sample charge: 1.The existing sample is free, only need 1day. 2.According to your design, need 2-3days. need the sample charge. 3.When ensure the PO, We will return back your sample charge. If you want to know more about our factory, please download the BV report in our home page.

We can supply wire harness assembly Sample charge: 1.The existing sample is free, only need 1day. 2.According to your design, need 2-3days. need the sample charge. 3.When ensure the PO, We will return back your sample charge. If you want to know more about our factory, please download the BV report in our home page. Related Keywords

Related Keywords