UL FEP extruded teflon wire

- Delivery Time:

- 3 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Jiangsu, China (Mainland) |

|---|

Product Description

Product Description

Specifications Extruded Teflon Wire

1.UL approved, RoHS Complian

2 High temperature resistance,anti-acid,anti-oil,antisepsis and mois

Extruded Teflon Wire

Extruded Teflon Wire

Product name : UL FEP extruded teflon wire

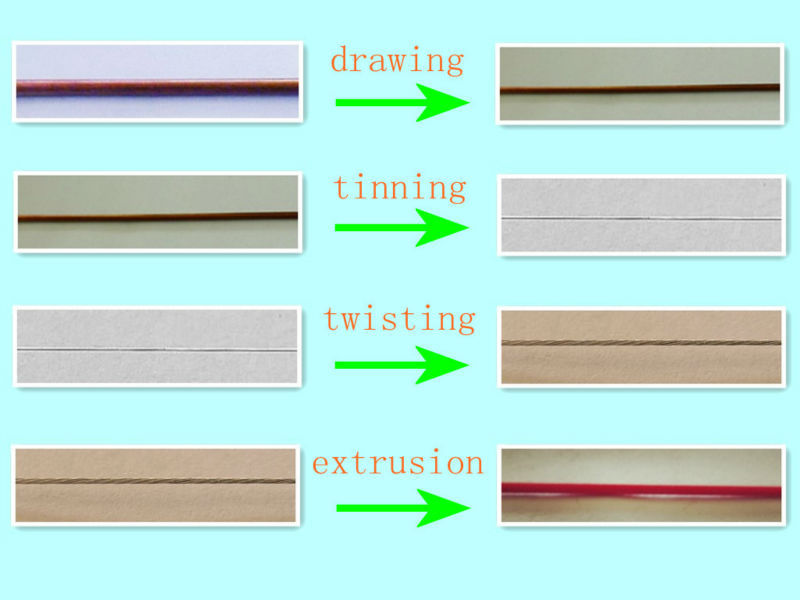

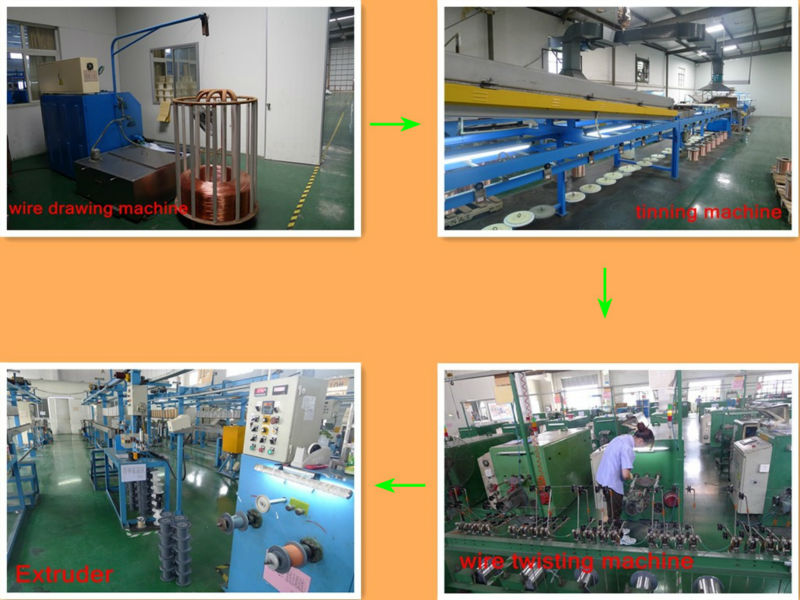

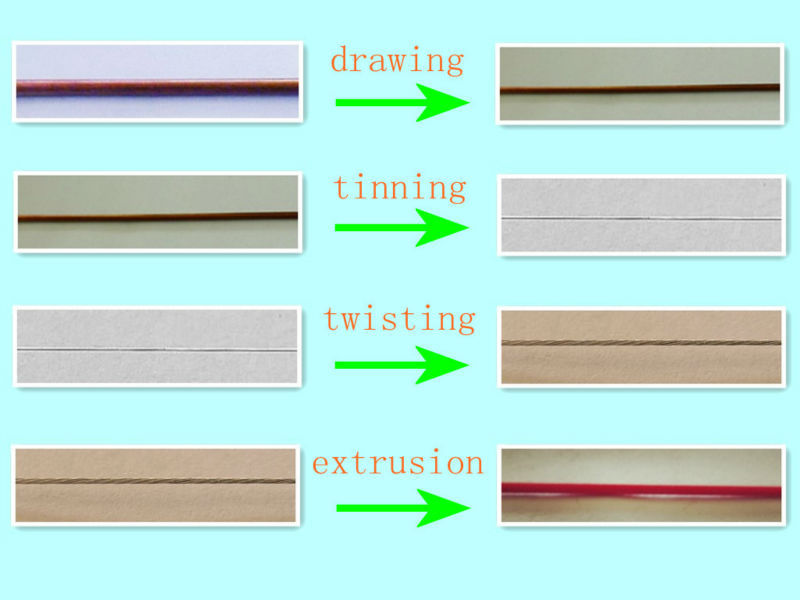

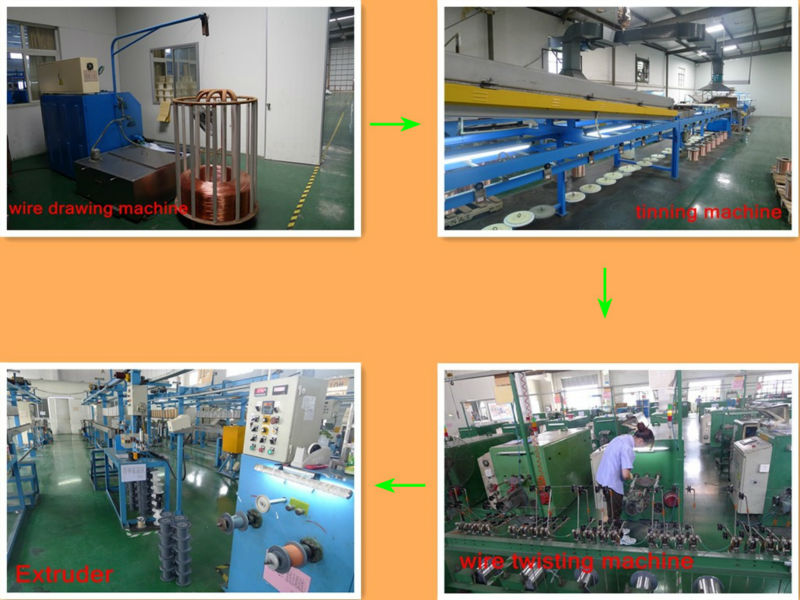

Advantage 1.Our company is a Teflon wire leader in domestic, and the supplier of world top 500, We have supplied wires for Apple company about 7 years. Our sales volume has definite proportion in global market. 2.Our wires are from 16AWG to 42AWG, wire diameter is between 1.8MM to 0.18MM. the Min tolerance is ±0.01, When OD<0.5mm, the tolerance is ±0.02 When 0.5mm<OD<1mm, the tolerance is ±0.03 When OD>1MM, the tolerance is ±0.05 3.Our production technology has four steps with drawing, tinning, stranding and extruding.Blister Copper is processed to Teflon wire with the lowest cost.We are the largest Teflon wire manufacturer with 16 Teflon extruders in domestic. The daily capacity can reach 3200KM. 4.We own advanced production equipments. Every Teflon wire extruder has touch screen control, outer diameter tester, Embossing machine and spark machine that ensure the quality of products. Application  Technical process

Technical process

Test equipment

Test equipment  Tester

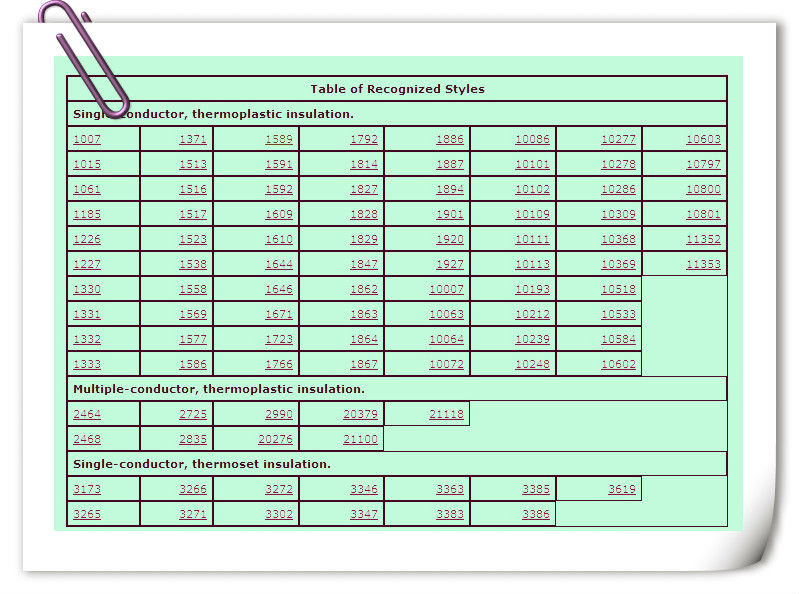

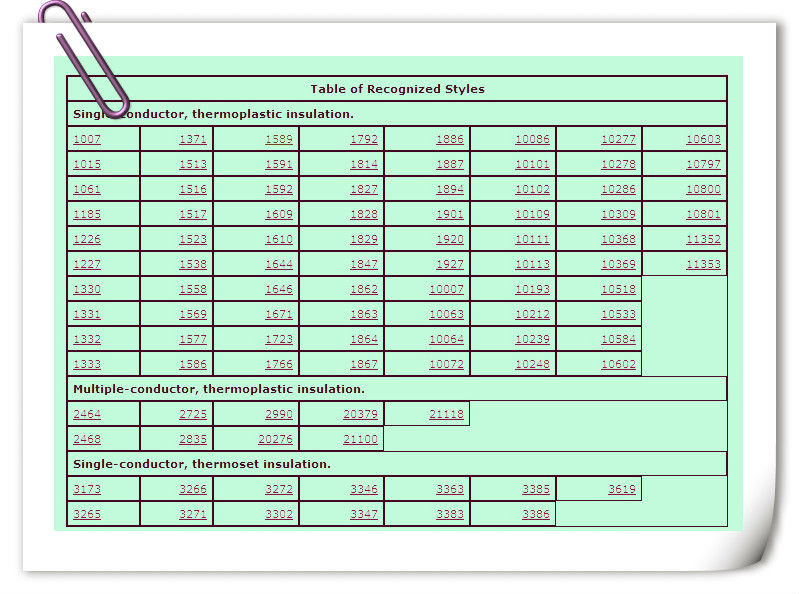

Tester  UL approved styles

UL approved styles  Packing

Packing  We can supply wire harness assembly Sample charge: 1.The existing sample is free, only need 1day 2.According to your design, need 2-3days.need the sample charge. 3.When ensure the PO, We will return back your sample charge. If you have interest, please contact us.

We can supply wire harness assembly Sample charge: 1.The existing sample is free, only need 1day 2.According to your design, need 2-3days.need the sample charge. 3.When ensure the PO, We will return back your sample charge. If you have interest, please contact us.

1.UL approved, RoHS Complian

2 High temperature resistance,anti-acid,anti-oil,antisepsis and mois

Extruded Teflon Wire

Extruded Teflon WireProduct name : UL FEP extruded teflon wire

| AWG | Specification | No. | Stranded Distance(mm) | Stranded OD(mm) | Stranded OD Tolerence(mm) | Singles Diameter Tolerence(mm) | Resistance (Max)Ω | |

| AWG42 | TPCA7/0.025 | A | <1.0 | 0.075 | ±0.02 | ±0.002 | 7500 | |

| AWG40 | TPCA7/0.03 | A | ≤1.3 | 0.090 | ±0.02 | ±0.003 | 5000 | |

| AWG38 | TA7/0.04 | A | 1~2 | 0.120 | ±0.02 | ±0.003 | 3300 | |

| AWG36 | TA7/0.05 | A | ≤2.5 | 0.150 | ±0.02 | 0.046~0.053 | 1500 | |

| TPCA19/0.03 | A | ≤2.5 | 0.150 | ±0.003 | ||||

| AWG34 | TA7/0.064 | A | 2~3 | 0.192 | ±0.02 | ±0.003 | 1040 | |

| TA12/0.05 | A | 2~3 | 0.200 | 0.046~0.053 | ||||

| TA19/0.04 | A | 3~4 | 0.200 | ±0.003 | ||||

| B | 2~3 | |||||||

| AWG32 | TA7/0.08 | A | 4~6 | 0.240 | ±0.02 | ±0.003 | 563 | |

| C | 3.5~4 | |||||||

| TA12/0.06 | A | 3~4 | 0.240 | ±0.003 | 563 | |||

| TA19/0.05 | A | 3~4 | 0.250 | 0.046~0.053 | 563 | |||

| B | <2.5 | |||||||

| AWG30 | TA7/0.1 | A | 5~7 | 0.300 | ±0.02 | 0.096~0.103 | 354 | |

| B | 2.5--3.5 | |||||||

| WX | 3~4 | |||||||

| TA12/0.08 | A | 3~5 | 0.320 | ±0.003 | ||||

| TA19/0.06 | A | 3~4 | 0.300 | ±0.003 | ||||

| B | 2~3 | |||||||

| AWG28 | TA7/0.127 | A | 5~7 | 0.381 | ±0.02 | 0.123~0.130 | 223 | |

| WX | 4~5 | |||||||

| TA19/0.08 | A | 4~6 | 0.400 | ±0.003 | ||||

| TA19/0.08 | B | 3~4 | 0.400 | |||||

| TA49/0.05 | A | 4~6 | 0.400 | 0.046~0.053 | ||||

| AWG27 | TA7/0.14 | A | 4~6 | 0.420 | ±0.02 | 0.136~0.143 | ||

| TA21/0.08 | A | 2~4 | 0.423 | ±0.003 | ||||

| AWG26 | TA7/0.16 | LW | ≤6.5 | 149 | ||||

| TA19/0.10 | A | 4~6 | 0.500 | 0.096~0.103 | ||||

| TA49/0.06 | A | 5~7 | 0.485 | ±0.003 | ||||

| AWG24 | TA7/0.20 | A | 7~9.5 | 0.609 | ±0.03 | 0.193~0.205 | 89.3 | |

| TA7/0.20 | B | 11±2 | ||||||

| TA19/0.127 | A | 8~9 | 0.635 | 0.123~0.130 | ||||

| TA41/0.08 | A | 5~8 | 0.592 | ±0.003 | ||||

| TA11/0.16 | A | 10~14 | 0.613 | ±0.005 | ||||

| AWG23 | TA21/0.127 | A | 9~11 | 0.672 | ±0.03 | 0.123~0.130 | 75 | |

| AWG22 | TA7/0.254 | A | ≤14.5 | 0.762 | ±0.03 | ±0.008 | 55 | |

| TA19/0.16 | A | 10~13 | 0.800 | ±0.005 | ||||

| AWG21 | TA19/0.18 | A | 13~17 | 0.900 | ±0.03 | ±0.005 | 45 | |

| AWG20 | TA7/0.32 | A | 17~21 | 0.960 | ±0.03 | 0.310~0.328 | 36.39 | |

| TA41/0.127 | A | 14~18 | 0.939 | 0.123~0.130 | 38.85 | |||

| AWG18 | TA16/0.254 | A | 9~13 | 1.173 | ±0.03 | 0.250~0.262 | 24.51 | |

| TA19/0.254 | A | 12~14 | 1.270 | ±0.008 | ||||

| TA49/0.16 | A | 18~22 | 1.294 | 0.158~0.165 | ||||

| TA65/0.127 | A | 18~22 | 1.183 | 0.123~0.130 | ||||

| AWG16 | TA19/0.30 | A | 19~21 | 1.500 | ±0.05 | ±0.008 | 13.7 | |

Technical process

Technical process

Test equipment

Test equipment  Tester

Tester  UL approved styles

UL approved styles  Packing

Packing  We can supply wire harness assembly Sample charge: 1.The existing sample is free, only need 1day 2.According to your design, need 2-3days.need the sample charge. 3.When ensure the PO, We will return back your sample charge. If you have interest, please contact us.

We can supply wire harness assembly Sample charge: 1.The existing sample is free, only need 1day 2.According to your design, need 2-3days.need the sample charge. 3.When ensure the PO, We will return back your sample charge. If you have interest, please contact us. Related Keywords

Related Keywords