VCI Masterbatch For Blowing VCI Film

- Delivery Time:

- 5 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Jiangsu, China (Mainland) |

|---|

Product Description

Product Description

VCI Masterbatch For Blowing VCI Film About us:

Suzhou Keysun Anti-rust Technology Co.,ltd is Anti-rust experts in China which has 15 years experience. Our company has a highly-efficient, professional, dedicated and cooperating group. In 2006, we furtherly strengthened our independent research and development research and development abilities, increased input in scientific research and established "keysun laboratory". Now our main product series includes: VCI masterbatch, VCI film & bag, VCI shrink film, stretch fil, VCI paper, VCI powder, VCI tablet & emitter. How VCI Master-batch Works: VCI Masterbatch, a base material used for producing VCI plastic film. It is a Nitrite Free anti corrosion masterbatch designed for both ferrous and most of the non ferrous metals. It can be blended with PP, LDPE, HDPE resin and then added to the film resin on the blowing and extruded to provide a new class of film product. Product Description:

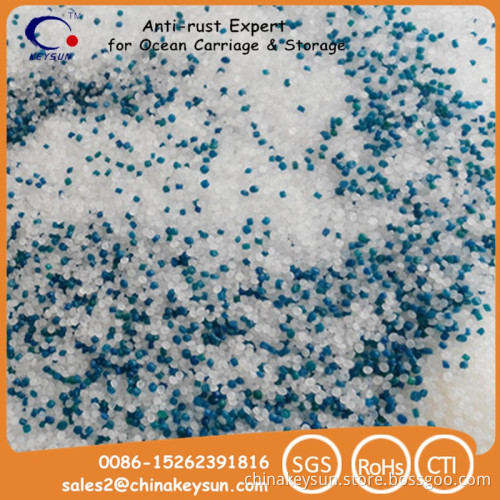

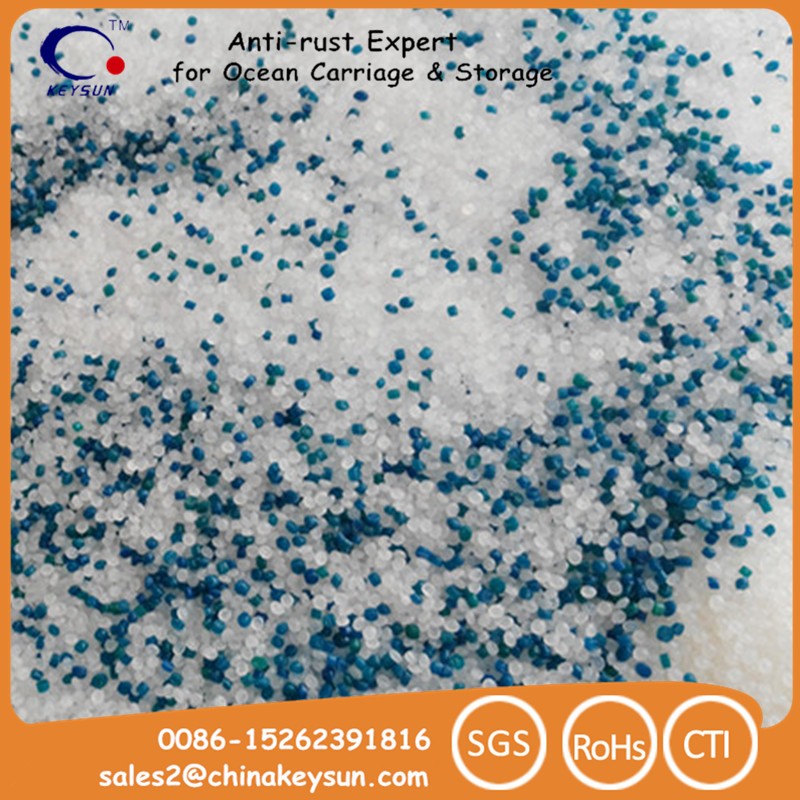

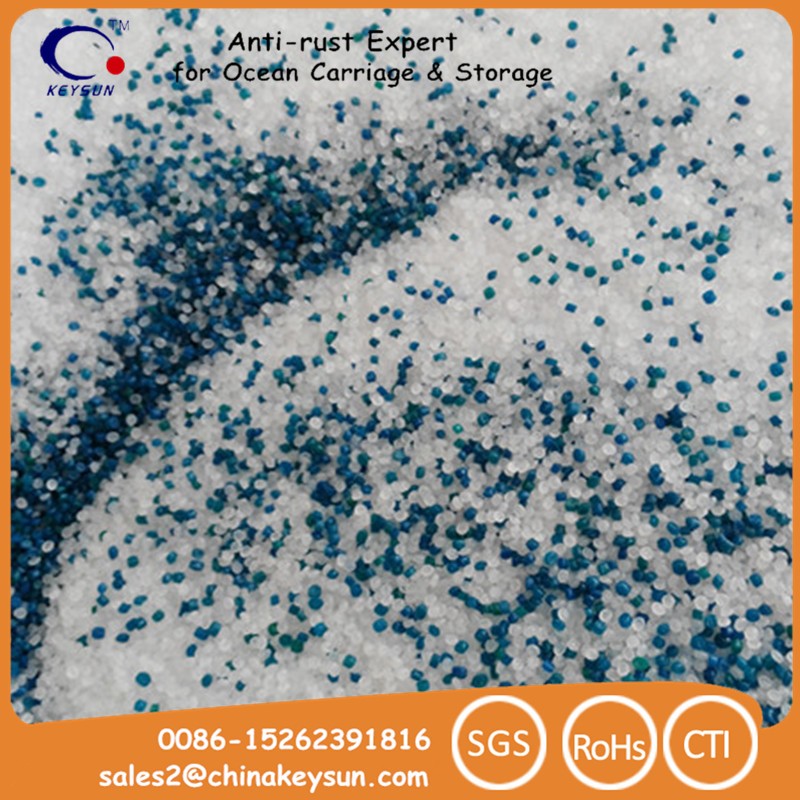

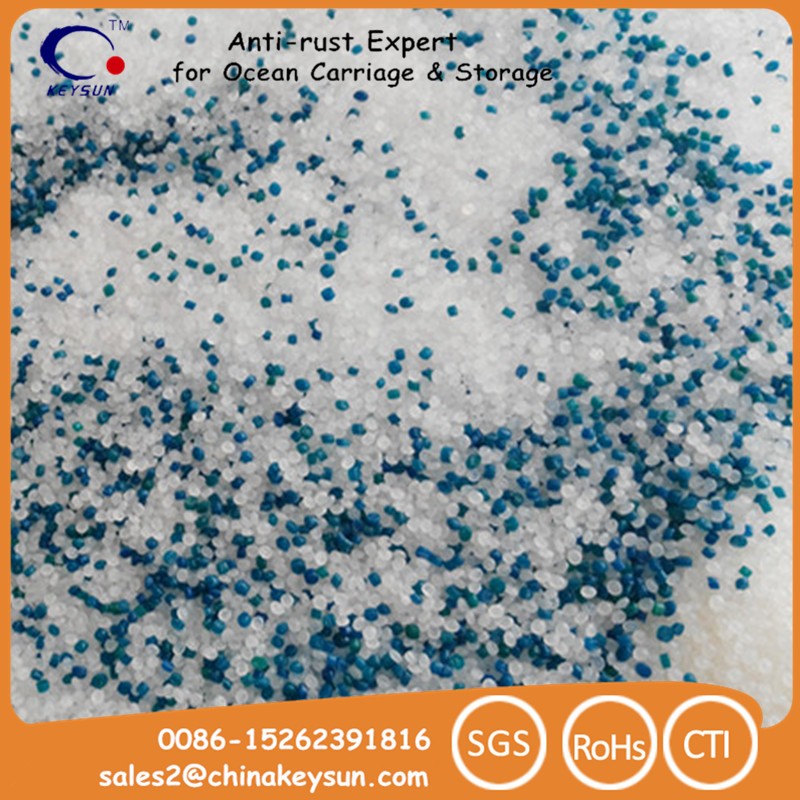

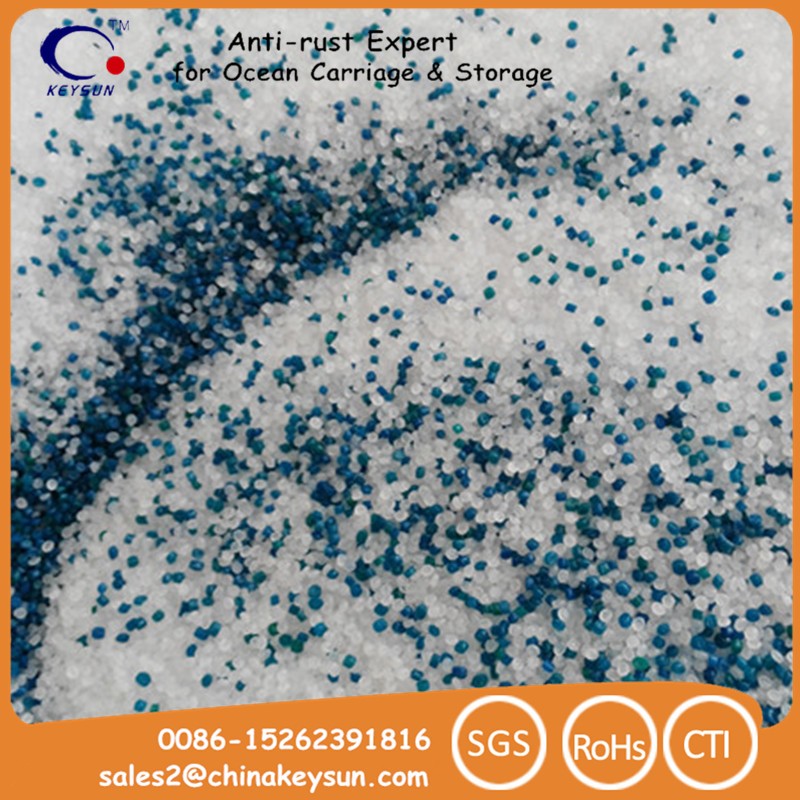

Product Display:

Features and Advantages: 1.The VCI plastic film with excellent performance can be produced with a small amount of such resin added to the formulation, the ratio is 2%. 2.The master batch is easy to operate and is extensively applicable to equipment and materials in selection. 3.Our master batch is eco-friendly and passes SGS certification and meets ROHS directives. Applicable Metals: It is applicable to both ferrous metal such as alloy steel, cast iron, and non-ferrous metal such copper, brass, bronze, plated metal, zinc and its alloy, chrome and its alloy, cadmium and its alloy, nickel and its alloy, tin and its alloy, aluminum and its alloy, and other metal materials and their products. Application Method: 1. Weigh and take the master batch and new PE granules according to the established formulation proportion, then mix them evenly and feed them for film blowing production. 2. The fusion range and mould head area temperature of blow moulding machine should be set according requirement, otherwise quality of VCI film will be affected. 3. It’s better to pay attention moisture and rain and fog weather when blowing film. Seal it again immediately after using. Custody and Storage: It should be sealed and kept in a cool, dry place, away from sunshine and no contact with sources of ignition and corrosive materials. The anti-rust period is 2 years or above. Trading Details

Features and Advantages: 1.The VCI plastic film with excellent performance can be produced with a small amount of such resin added to the formulation, the ratio is 2%. 2.The master batch is easy to operate and is extensively applicable to equipment and materials in selection. 3.Our master batch is eco-friendly and passes SGS certification and meets ROHS directives. Applicable Metals: It is applicable to both ferrous metal such as alloy steel, cast iron, and non-ferrous metal such copper, brass, bronze, plated metal, zinc and its alloy, chrome and its alloy, cadmium and its alloy, nickel and its alloy, tin and its alloy, aluminum and its alloy, and other metal materials and their products. Application Method: 1. Weigh and take the master batch and new PE granules according to the established formulation proportion, then mix them evenly and feed them for film blowing production. 2. The fusion range and mould head area temperature of blow moulding machine should be set according requirement, otherwise quality of VCI film will be affected. 3. It’s better to pay attention moisture and rain and fog weather when blowing film. Seal it again immediately after using. Custody and Storage: It should be sealed and kept in a cool, dry place, away from sunshine and no contact with sources of ignition and corrosive materials. The anti-rust period is 2 years or above. Trading Details

Certification Show: Factory Pictures: welcome to our factory and we will be glad to build nice business relationship with u. Any question pls feel free to contact with us!

Suzhou Keysun Anti-rust Technology Co.,ltd is Anti-rust experts in China which has 15 years experience. Our company has a highly-efficient, professional, dedicated and cooperating group. In 2006, we furtherly strengthened our independent research and development research and development abilities, increased input in scientific research and established "keysun laboratory". Now our main product series includes: VCI masterbatch, VCI film & bag, VCI shrink film, stretch fil, VCI paper, VCI powder, VCI tablet & emitter. How VCI Master-batch Works: VCI Masterbatch, a base material used for producing VCI plastic film. It is a Nitrite Free anti corrosion masterbatch designed for both ferrous and most of the non ferrous metals. It can be blended with PP, LDPE, HDPE resin and then added to the film resin on the blowing and extruded to provide a new class of film product. Product Description:

Item | VCI Masterbatch Rust-proof Filler Masterbatch |

| Model No. | keysun2100 |

| Eco-friendly | yes we have passed MSDS,SGS,CTI,ROHS |

| Color | regular ivory or off-white other color, u can add color masterbatch when production |

| Ratio | 2% |

| Heat resistance | 200 degree centigrade |

| Metal protected | ferrous metal and non-ferrous metal |

| Usuage | anti-rust additive for film blowing |

| Anti-rust period | 2 years |

| Charater | functional master-batch |

Features and Advantages: 1.The VCI plastic film with excellent performance can be produced with a small amount of such resin added to the formulation, the ratio is 2%. 2.The master batch is easy to operate and is extensively applicable to equipment and materials in selection. 3.Our master batch is eco-friendly and passes SGS certification and meets ROHS directives. Applicable Metals: It is applicable to both ferrous metal such as alloy steel, cast iron, and non-ferrous metal such copper, brass, bronze, plated metal, zinc and its alloy, chrome and its alloy, cadmium and its alloy, nickel and its alloy, tin and its alloy, aluminum and its alloy, and other metal materials and their products. Application Method: 1. Weigh and take the master batch and new PE granules according to the established formulation proportion, then mix them evenly and feed them for film blowing production. 2. The fusion range and mould head area temperature of blow moulding machine should be set according requirement, otherwise quality of VCI film will be affected. 3. It’s better to pay attention moisture and rain and fog weather when blowing film. Seal it again immediately after using. Custody and Storage: It should be sealed and kept in a cool, dry place, away from sunshine and no contact with sources of ignition and corrosive materials. The anti-rust period is 2 years or above. Trading Details

Features and Advantages: 1.The VCI plastic film with excellent performance can be produced with a small amount of such resin added to the formulation, the ratio is 2%. 2.The master batch is easy to operate and is extensively applicable to equipment and materials in selection. 3.Our master batch is eco-friendly and passes SGS certification and meets ROHS directives. Applicable Metals: It is applicable to both ferrous metal such as alloy steel, cast iron, and non-ferrous metal such copper, brass, bronze, plated metal, zinc and its alloy, chrome and its alloy, cadmium and its alloy, nickel and its alloy, tin and its alloy, aluminum and its alloy, and other metal materials and their products. Application Method: 1. Weigh and take the master batch and new PE granules according to the established formulation proportion, then mix them evenly and feed them for film blowing production. 2. The fusion range and mould head area temperature of blow moulding machine should be set according requirement, otherwise quality of VCI film will be affected. 3. It’s better to pay attention moisture and rain and fog weather when blowing film. Seal it again immediately after using. Custody and Storage: It should be sealed and kept in a cool, dry place, away from sunshine and no contact with sources of ignition and corrosive materials. The anti-rust period is 2 years or above. Trading Details | Sample: | sample available for quality checking, don't hesitate to tell us if u need. |

| Certification: | we have been in this field for 15 years, our products with good quality and have passed ISO 9001 : 2003, SGS, CTI, ROHS |

| Lead time: | 5-7 days it also depends on your order quantity season u place order. |

| Trade terms: | EXW, FOB, CNF,CIF |

| Packing: | standard export package or upon request. |

| Shipping: | for small order: express delivery such as TNT,FEDEX,UPS,DHL,EMS for bulk production: sea freight, air freight both ok, according to your requirement. |

| Payment: | for small order: 100% paid before shipping. for bulk production: 30% deposit, balance paid at sight of B/L copy. |

Related Keywords

Related Keywords