Automatic PE Film Shrink Wrapping Machine

-

$10000.00≥1 set

- Min. Order:

- 1 set

- Min. Order:

- 1 set

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Payment Type: | L/C,Western Union,T/T |

|---|

Product Description

Product Description

About US

US Zhangjiagang AQUA Machinery co.,Ltd is a Professional Beverage Filling Machine supplier More Than 10 years.

We Had 3 Skilled Sales With More than 8 Years' experience, So We will give MOST Professional suggestions as Our Experience and NOT Recommend The Most Expensive Cost.

We Are Looking For long-term development with customers, not a low-cost sales route, Quality is The First Consideration

We focus on Providing Safe,Efficient Equipment and Higher Quality, Fast And Personalizes Service.

Our Aim is Helping Customers To get Profit and We'll Establish Long Term Relationship

PE Heat Shrink Wrap Machine / Automatic PE Film Shrink Wrapping Machine

Full automatic shrink packaging machine can not only be solely used, but used simultaneously with other equipment to form packaging production line. It can automatically array, aggregate and align PET beverage bottle or other similar articles, then package it with shrinking film, finally produce finished products after shrinking by heating, cooling and forming. The packaged product is firmly bound with excellent appearance, which can be opened conveniently. Therefore, it is widely used in industries such as foodstuff, medicine, chemical and other light industrial products.

1) The temperature can be controlled automatically and changed as required.

2) Isothermal sealing cutter

3) Original guide bar cylinder with steady operation

4) Programmable logic controller (PLC) control

5) Non bottom support packaging, suitable for package with different bottle diameters and different combinations

6) Simple operation and easy repair.

No. Items Parameters

1 Maximum package size 400×300×400 (height) mm

2 Largest Bottle diameter 450×300×400 (height)

3 Length of heat-sealing knife 700mm

4 Shrinkage temperature 130-260℃

5 Contraction time 0-6s

6 Heat sealing and cutting temperature 150-200℃

7 Maximum production speed 600 BPS/h

8 Number of bottles per package (round or square)

9 4 columns 4 x 6 4 x5 applicable bottle size 4 x 4 Ф 40 - Ф 70 mm

10 3 columns 3 x 3 applicable bottle size 3 x 4 Ф 70 - Ф 98 mm

11 2 columns 2 x 3 bottle diameter 2 x 4 Ф 98 - Ф 140 mm

12 1 column 1 x 2 x 1 applicable bottle diameter 1 x Ф140 - Ф300 mm

1 Maximum package size 400×300×400 (height) mm

2 Largest Bottle diameter 450×300×400 (height)

3 Length of heat-sealing knife 700mm

4 Shrinkage temperature 130-260℃

5 Contraction time 0-6s

6 Heat sealing and cutting temperature 150-200℃

7 Maximum production speed 600 BPS/h

8 Number of bottles per package (round or square)

9 4 columns 4 x 6 4 x5 applicable bottle size 4 x 4 Ф 40 - Ф 70 mm

10 3 columns 3 x 3 applicable bottle size 3 x 4 Ф 70 - Ф 98 mm

11 2 columns 2 x 3 bottle diameter 2 x 4 Ф 98 - Ф 140 mm

12 1 column 1 x 2 x 1 applicable bottle diameter 1 x Ф140 - Ф300 mm

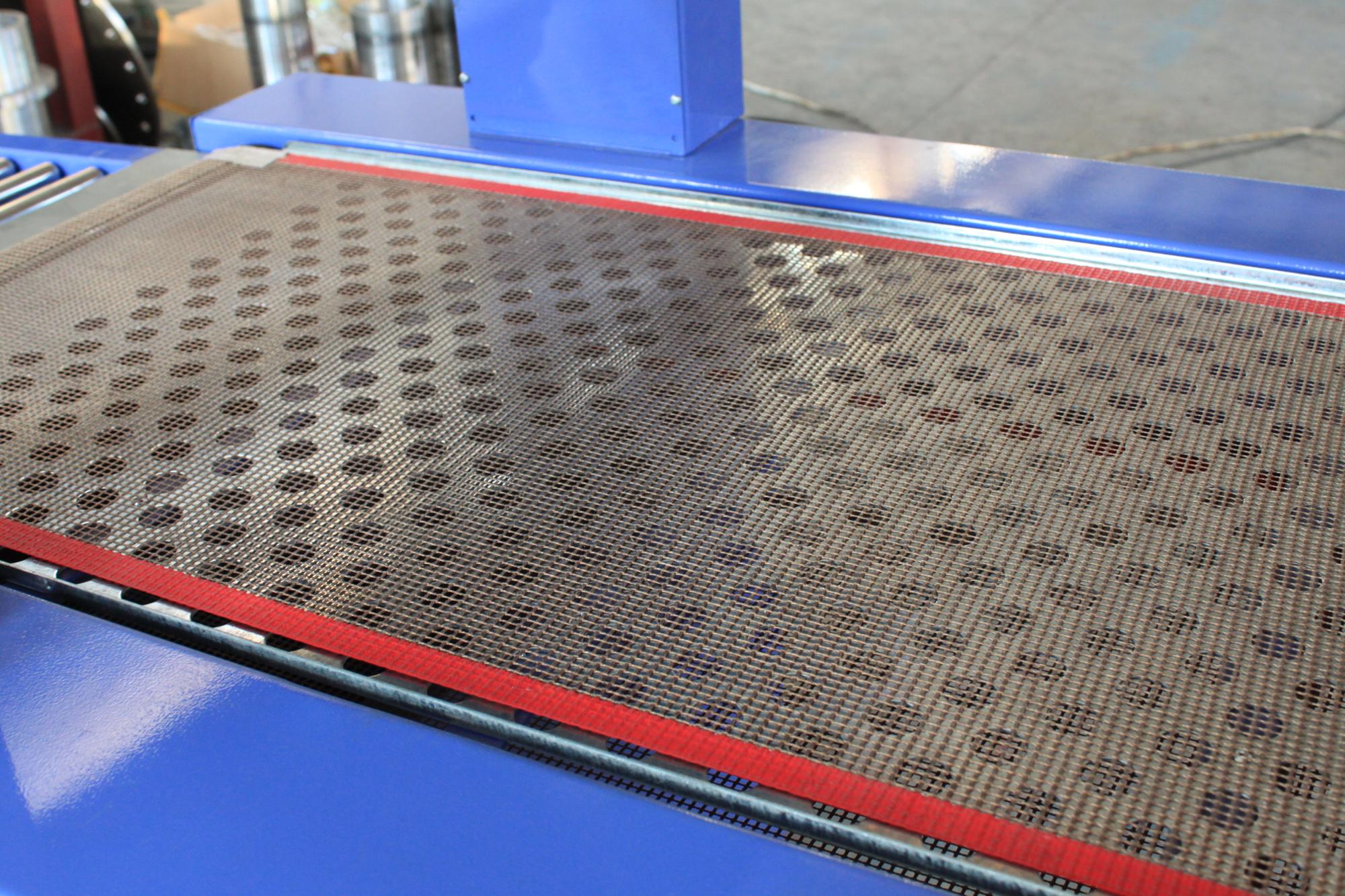

Conveyor

transfer bottles into packing machine

Belt

belt which can afford high temperature and transfer packed bottles out

Roller Conveyor

Transfer bottles out automatic

AQUA MACHINE ------------- Main Focus On Different Bottled Liquid Filling Packing Project A To Z

Related Keywords

Related Keywords

You May Also Like

You May Also Like