Complete Soda Water Filling Line Solution

-

$24000.00≥1 set

- Min. Order:

- 1 set

- Min. Order:

- 1 set

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

Product Description

Product Description

Complete Solution For Carbonated Water/Soda Line/Complete Soda Water Filling Line

Complete Solution For Carbonated Water/Soda Line

Model: CGFD32-32-8

Capacity: 10000BPH

Filling Type: Isobaric Filling

Bottle Size: 500ml-2000ml PET Bottle

Control: PLC+Touch Screen

Include: Air conveyor+Bottle Washer Filler Capper+Auto Cap Loader+ Filled Conveyor

Electric Configuration: SIEMENS / MITSUBISH /DANFOSS etc

All Material: SUS304/316 Food GradeMotor: SEW /ABB Brand

Rinser

Filler

Capper

Complete Line Solution

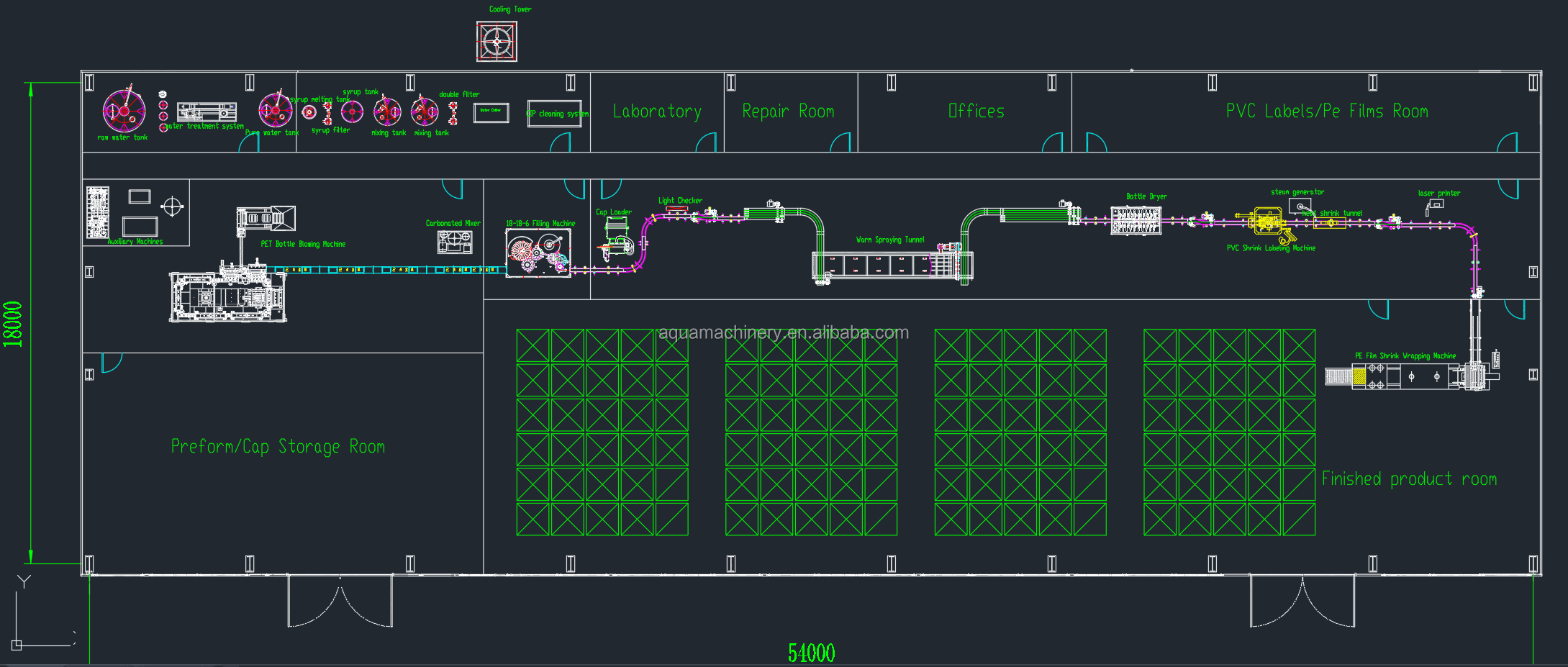

Complete Solution For Carbonated Water/Soda Line -- Drawing

PRODUCT SPECIFICATIONS

Model | CGF 8-8-3 | CGF 16-16-5 | CGF24-24-8 | CGF32-32-10 | CGF 40-40-12 | ||||||

Rinsing nozzles | 8 | 16 | 24 | 32 | 40 | ||||||

Filling nozzles | 8 | 16 | 24 | 32 | 40 | ||||||

Capping nozzles | 3 | 5 | 8 | 10 | 12 | ||||||

Output(@500ml) | 2000BPH | 3000BPH | 6000BPH | 10000BPH | 12000BPH | ||||||

Applicable bottle size | Diameter=50~108mm, H=170~340mm, 330~2250ml | ||||||||||

Pressure of air source | 0.7MPa | 0.7MPa | 0.7MPa | 0.7MPa | 0.7MPa | ||||||

Air Consumption | 0.25M3/min | 0.8 | 0.8 | 0.8 | 0.8 | ||||||

Pressure of water | 0.2-0.25MPa | ||||||||||

Pressure of filling | 0.2-0.3MPa | ||||||||||

Power consumption | 2.5kw | 3.5kw | 5kw | 6.5kw | 7.5kw | ||||||

Machine body | SS304/S316 | ||||||||||

Machine size L*W*H | 2100*1800*2400 | 2300*2200*2400 | 3000*2200*2800 | 4000*2600*2800 | 4700*2900*2800 | ||||||

Machine weight(kg) | 2500 | 3000 | 4000 | 5000 | 6000 | ||||||

Product Overview

Water Treatment System -- Purify groudwater or tap water to be cleaning and drinking.

1.Include Raw water pump ,Sand filter, Active carbon filter, Sodium filter, Precison filter

2. Dosing system

3.RO / Hollow ultrafiltration device

4.UV sterilizer / Ozone sterilizer

4.UV sterilizer / Ozone sterilizer

5. Storage Tank

Beverage Drink Mixing Machine -- Mixing CO2 with water and syrup,additives

1.Sugar melting tank+Sugar pump+Sugar filter

2.Blending tank+Sugar pump+Double filter

3.Cooling-water machine+Plate heat exchanger+Carbonated water generator

4.CIP cleaning system

3.Cooling-water machine+Plate heat exchanger+Carbonated water generator

4.CIP cleaning system

Carbonated Water/Soda Filling Machine

1. Washing bottle --- CO2 into bottle --- CO2 --- Vacuum --- Filling CSD --- Capping

2. Isobaric Filling Method

3. High filling speed and accurate liquid level control

4. PLC control, high degree of automation

3. High filling speed and accurate liquid level control

4. PLC control, high degree of automation

Spraying Warm/Cool Tunnel -- soft drink adopt balance pressure filling which filling temperature aound 5, so after fill, it needs spraying tunnel for warming drink temperature for labeling and packing.

1.It was used for warming filled soft drinks to be room temperature

2.Smooth and reliable operation with low energy consumption

3. Two or Three temeprature controlling area

4. Steam Bolier heating water for spraying

PVC Shrink Labeling Machine -- put and cut label on bottles then shrinking label on bottle

1.Good stability and long service life

2.Simple structure can ensure low failure rate and simple maintenance.

3.Applicable to various bottle types: round bottle, square bottle, oval bottle, etc

4.Low cost blade, low maintenance cost of consumables

3.Applicable to various bottle types: round bottle, square bottle, oval bottle, etc

4.Low cost blade, low maintenance cost of consumables

PE Film Shrink Wrapping Machine -- packing filled bottles as 4*6 or 3*4 etc.

1.Low cost of consumables can ensure low cost of finished products

2.Stable operation and fast labeling

3.Good packaging effect, tight shrinkage and beautiful appearance

4.Small size, short preheating time and power saving

3.Good packaging effect, tight shrinkage and beautiful appearance

4.Small size, short preheating time and power saving

Recommend Products

Successful Project

Project in Armenia

6000BPH 500ML WATER FILLING LINE

Project in Thailand

4000CPH 335ML CANNING LINE

Project in Haiti

4000BPH 500ML JUICE FILLING LINE

Related Keywords

Related Keywords

You May Also Like

You May Also Like