12000bph Bottled Water Production Plant

-

$25000.00≥1 set

- Min. Order:

- 1 set

- Min. Order:

- 1 set

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

Product Description

Product Description

Product Overview

AQUA MACHINE - Main Focus On Different Bottled Liquid Filling Packing Project A To Z

12000bph Bottled Water Production Plant Drinking Water Packaging Plant

It is the ideal equipment for mineral water, distilled water and purified water producing process. This machine composed with Rinse filler and capper, adopt cylinder cap press, with cap return function, cap sorter can keep one hour cap consummation , Rinsing pressure will be displayed,

The main electrical parts adopt products with brand of Siemens and OMRON. Pneumatic parts adopt products with brand of AIRTAC. Both the inner and outer shower nozzle for washing barrel adopts the special technology equipment from American Sprayer Company.

The machine works reliably and efficiently based on the compact structure and high automatic technology. It Is the fully automatic barreled water producing equipment combined with machine, electronic and pneumatic component

The main electrical parts adopt products with brand of Siemens and OMRON. Pneumatic parts adopt products with brand of AIRTAC. Both the inner and outer shower nozzle for washing barrel adopts the special technology equipment from American Sprayer Company.

The machine works reliably and efficiently based on the compact structure and high automatic technology. It Is the fully automatic barreled water producing equipment combined with machine, electronic and pneumatic component

Product Paramenters

Model | CGF 24-24-8 Bottled Water Production Plant Drinking Water Packaging Plant |

Capacity | 12000BPH |

Rinser Head | 24 |

Filling Head | 24 |

Capping Head | 8 |

Suitable Bottle | PET Bottle ( Round/Flat) |

Bottle Dates | Bottle Diameter is 55mm-110mm / Bottle Height is 150mm-310mm |

Cap Type | Screw Cap 28mm or 30mm |

Power | 3.5KW |

Control | PLC Control |

Size Of Machine | 2300*2200*2360mm |

Products Description

Rinser Part

<1>All 304/316stainless steel rinse heads, water spray style inject design, more save water consumption and more clean

<2>304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing

Filling Part

<1> 304/316 Stainless steel high precision filling nozzle

<2> Filling volume adjustable in fine rank, same liquid level after filling

<3> All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

<3> All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

Capping Part

<1> Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during

capping

capping

<2> All 304/316 stainless steel construction

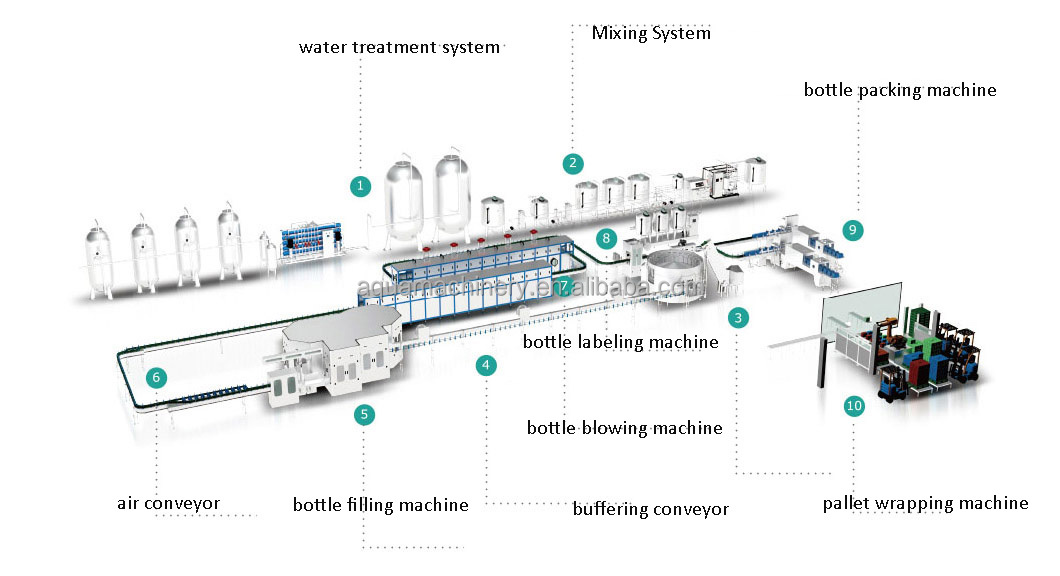

Auxiliary Equipment

Water Treatment System

Can remove 97% of the impurity and bad materials.

Can produce high quality and good taste water.

We installed water pressure and water level protecting device on the water inlet parts before the high pressure pump to protect machine, after you start the machine, when the water pressure and water level reached the setting value the machine would start auto, if below it will auto stop.

Equipped with conductivity on line monitor can tell you the water quality every time. · Safe design.

Can produce high quality and good taste water.

We installed water pressure and water level protecting device on the water inlet parts before the high pressure pump to protect machine, after you start the machine, when the water pressure and water level reached the setting value the machine would start auto, if below it will auto stop.

Equipped with conductivity on line monitor can tell you the water quality every time. · Safe design.

PET Bottle Blowing Machine

· Man-machine Interface control, easy to operate

· Automatic preform loading and unscrambling

· Preform hopper

· Close structure, low contamination

· Well preform heating system

· Stable rotating system

· Preforms are evenly heated, and easy to blow

· Low energy consumption, heating capacity is adjustable

· Automatic preform loading and unscrambling

· Preform hopper

· Close structure, low contamination

· Well preform heating system

· Stable rotating system

· Preforms are evenly heated, and easy to blow

· Low energy consumption, heating capacity is adjustable

Automatic PVC Shrink Labeling Machine

Suitable for Auto Sticker labeling machine

Automatic PVC Shrink Labeling Machine

Shrink Tunnel

Steam Generator

Automatic BOPP hot Glue Labeling Machine

Automatic Shrink Wrapping Machine

.Once your beverage product has been filled and the bottle has been labelled, the primary package is gently transferred using conveyors to its secondary packaging process.

.The final result is the package the customer sees at the point of sale, so it needs to grab their attention.

.These packs ensure protection from elements such as weather, pressure and temperature changes.

.The final result is the package the customer sees at the point of sale, so it needs to grab their attention.

.These packs ensure protection from elements such as weather, pressure and temperature changes.

Working Team

Our Guarantee For customers

Even new customers can place orders with confidence, Alibaba provides buyers with 100% guarantee 。

You May Also Like

You May Also Like