New PET Bottle Water Line Bottling System for 330ml, 500ml, 750ml, and 1L

-

$11000.00≥1 set

- Min. Order:

- 1 set

- Min. Order:

- 1 set

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

Product Description

Product Description

Our Advantages

About Aqua Machinery

We located in zhangjiagang city jiangsu province, it is near to shanghai airport

Our advantage:

1.stable machinery quality : IT 7 tolerance

2.professional engineer team

3.good after service : Reply Customers in time and Give the solution in 24 hours.

1.stable machinery quality : IT 7 tolerance

2.professional engineer team

3.good after service : Reply Customers in time and Give the solution in 24 hours.

New Type Bottling System For 330ml 500ml 750ml 1L PET bottle Water Line

Video is a complete Project from A to z Complete Water Bottling Line

Start from Bottle Blowing machine, Water Filling machine, Labeling machine and packing machine.

Products Description

New Type Bottling System For 330ml 500ml 750ml 1L PET bottle Water Line

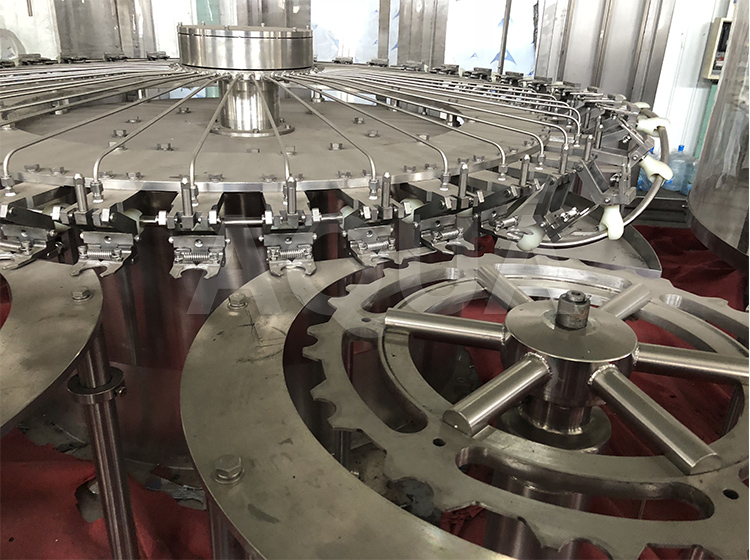

Function: rinse filler capper and cap sterilize, automatic cap loader

Application: water, juice, carbonated drink, beer, edible oil, vinegar etc

Material: SUS 304 Material (From Pohong Group)

Equipment processing accuracy : IT 7 tolerance

Rinse

filler

capper

Model | Production(B/H) | bottle type | Weight (KG) | POWER (KW) |

CGF 8-8-3 | 2000 | PET round or square bottle Volume 200 - 2000ml Bottle diameter 50-115mm Bottle height 160-320mm | 1900 | 2.2 |

CGF 14-12-5 | 4000 | 2400 | 3.15 | |

CGF 16-16-5 | 6000-8000 | 3000 | 4.2 | |

CGF 24-24-8 | 10000-12000 | 4000 | 5.5 | |

CGF 32-32-10 | 15000 | 4800 | 6.7 | |

CGF 40-40-10 | 180000-22000 | 5500 | 9 |

PRODUCT CONFIGURATION

CHANGCHAI high power engine

Imported EATON control valve

Japan Shimadzu hydraulic motor

Successful Project

Project in Guinea Bissau

Production : 1200bph

Bottle volume : 5 gallon

complete line from automatic blowing machine to palletizer

Project in Armenia

7000bph 500ml water bottling line

From automatic blowing machine to PE film wrapping machine

Project in Mongolia

600bph 5L water filling line

From bottle blowing machine to packing machine

SIMILAR PRODUCTS

juice filling machine

2000-35000 B/H

edible oil / cooking oil bottling machine

1000-3000 B/H

beer or wine filling machine

Aluminum can or glass bottle

Auxiliary Equipment

Hot glue labeling machine

1.Normally Hot glue labeling machine is used for high speed machine

2.we also supply sleeve labeling machine, stick labeling machine

PE film wrapping machine

Put the bottles in one group.

for example: 3x4, 4 x6 , 2x3 etc.

Customer Photos

Zhangjiagang Aqua Machinery CO.,Ltd

1 / Standardized workshop of total 20,000 square meters.

2 / The equipment will be tested and run for 24 hours before leaving the factory, to ensure the smooth working of water pipeline,

and pneumatic, electrical and mechnical stability.

3 / Sufficient stock of spare parts ensures the timely delivery and supply of spare parts.

2 / The equipment will be tested and run for 24 hours before leaving the factory, to ensure the smooth working of water pipeline,

and pneumatic, electrical and mechnical stability.

3 / Sufficient stock of spare parts ensures the timely delivery and supply of spare parts.

Our Team

1 / Professional installation team who can speak fluent English can help customers make benefits in a shortest time.

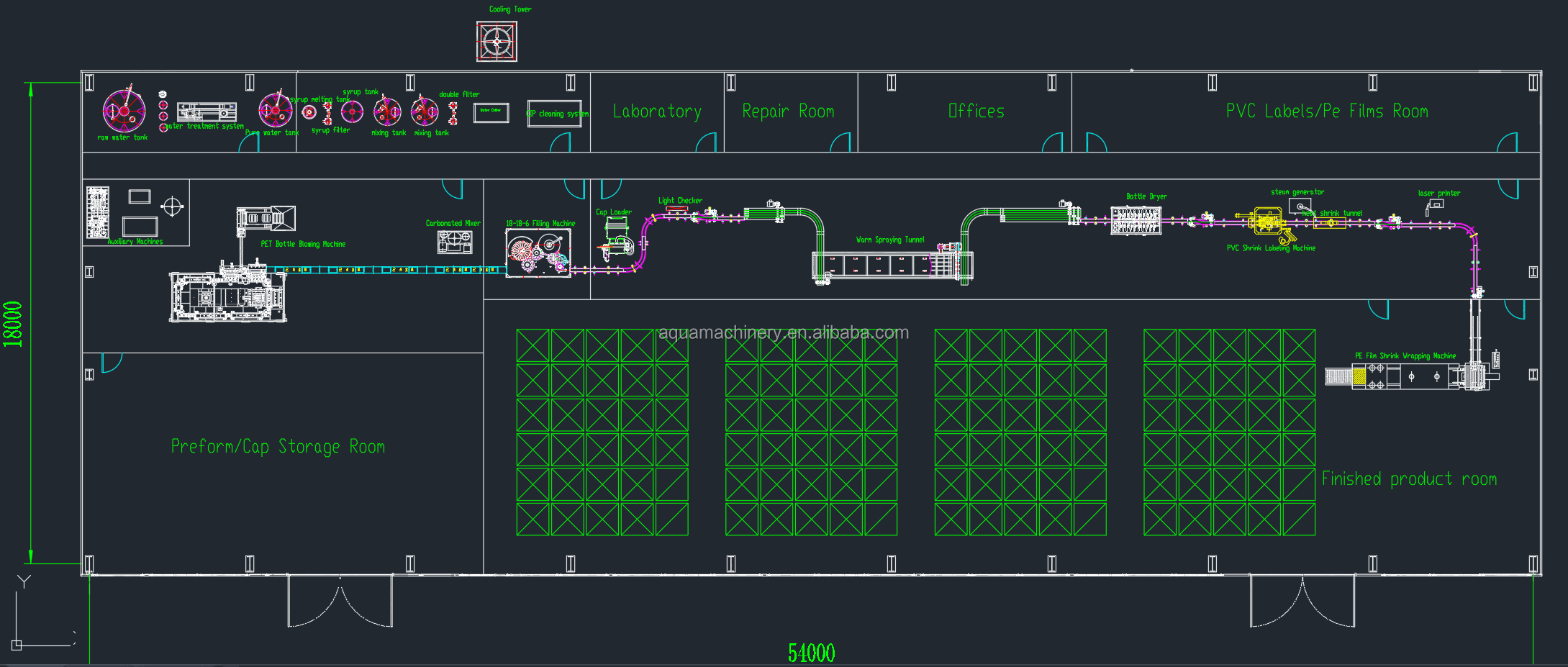

2 / The engineers are experienced. We can produce different products with different capacity and work out reasonable flow chart as

per customers' requirements to save space.

2 / The engineers are experienced. We can produce different products with different capacity and work out reasonable flow chart as

per customers' requirements to save space.

Certifications

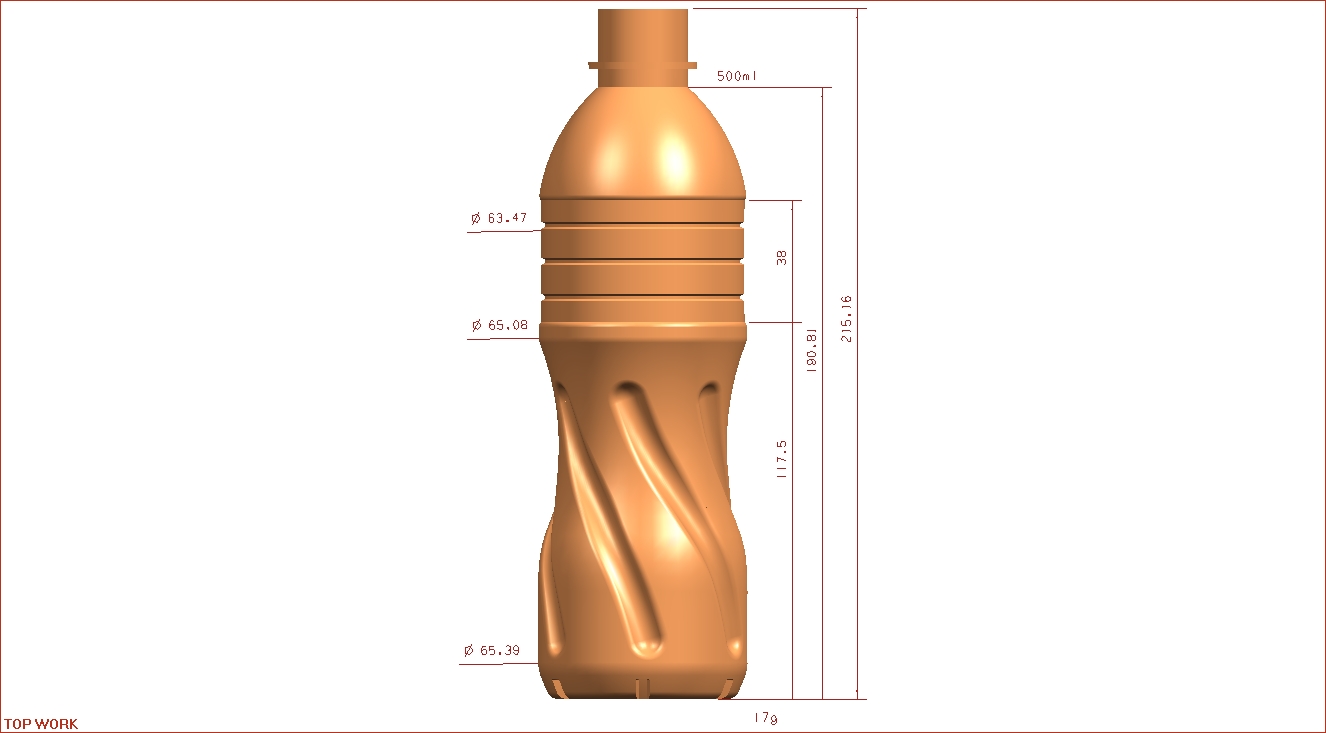

Bottle Design.

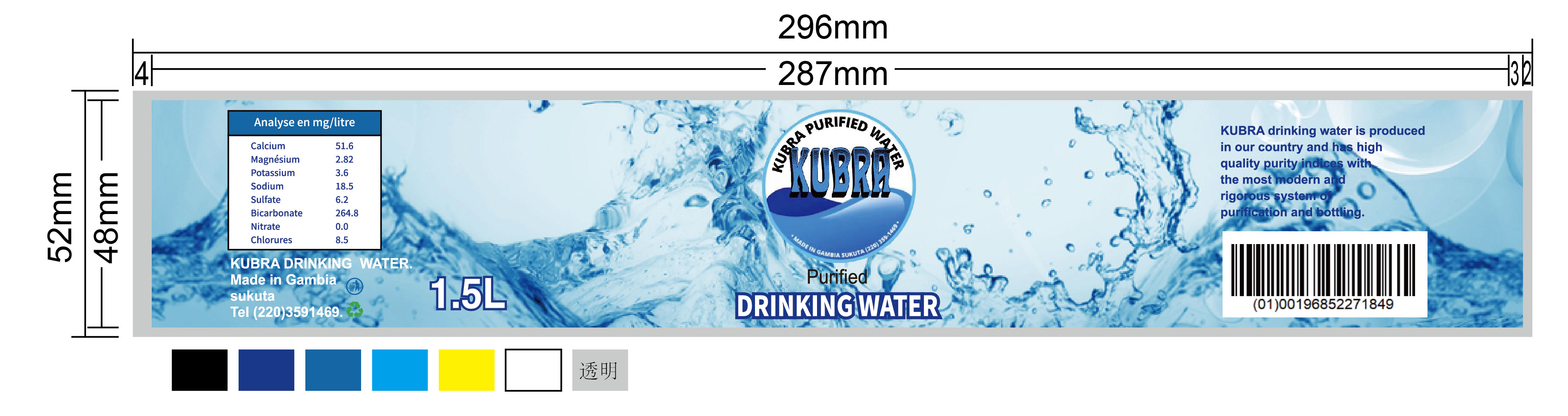

Label design

Layout design

we can make design based on customer's factory drawing.

FAQ

HOW TO GUARANTEE YOUR FUNDS TO BE SAFE AND DELIVERY TO BE ON TIME?

● Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to buy.

● After the factory visit, You can ensure the facticity of our bank account.

SEE AQUA MACHINERY HOW TO ENSURE THE QUALITY!

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have

accumulated professional processing methods over the past years.

● Each component before assembly needs strictly control by inspecting personnel.

● Each assembly is in charged by a master who has working experience for more than 5 years

●After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to

ensure the stable running in customers' factory

THE AFTER-SALE SERVICE OF AQUA MACHINERY!

● After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or

instant tools

● After the commissioning, we will package the equipment by standard export package for shipment.

● According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

● Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the

customers' project.

● Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to buy.

● After the factory visit, You can ensure the facticity of our bank account.

SEE AQUA MACHINERY HOW TO ENSURE THE QUALITY!

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have

accumulated professional processing methods over the past years.

● Each component before assembly needs strictly control by inspecting personnel.

● Each assembly is in charged by a master who has working experience for more than 5 years

●After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to

ensure the stable running in customers' factory

THE AFTER-SALE SERVICE OF AQUA MACHINERY!

● After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or

instant tools

● After the commissioning, we will package the equipment by standard export package for shipment.

● According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

● Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the

customers' project.

Related Keywords

Related Keywords

You May Also Like

You May Also Like