Semi-Automatic 5L 10L Jerry Can Plastic Bottle Blowing Machine

-

$6500.00≥1 set

- Min. Order:

- 1 set

- Min. Order:

- 1 set

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Payment Type: | L/C,T/T |

|---|

Product Description

Product Description

Product Overview

Bottle Blowing machine / PET Bottle Blowing Machine / PET Bottle Making Machine.

1.AM series linear bottle blowing machine features: 1.stable and accurate running at high speed,adopt more stable and advanced microcomputer PLC control system.

2. production process is fully automated, with the advantages of low investment, high efficiency, easy operation, simple

maintenance and safety.

3. suitable for flexible production of quantity and various bottle

shape,wide range of applications,meet customer needs.

4. manual and automatic methods of operation, human-machine interface

control, simple operation.

5. servo transmission system, high positioning accuracy, fast speed stability and good reliability.

6.less than 0.2% scrap rate for finished bottle .

2. production process is fully automated, with the advantages of low investment, high efficiency, easy operation, simple

maintenance and safety.

3. suitable for flexible production of quantity and various bottle

shape,wide range of applications,meet customer needs.

4. manual and automatic methods of operation, human-machine interface

control, simple operation.

5. servo transmission system, high positioning accuracy, fast speed stability and good reliability.

6.less than 0.2% scrap rate for finished bottle .

Details Images

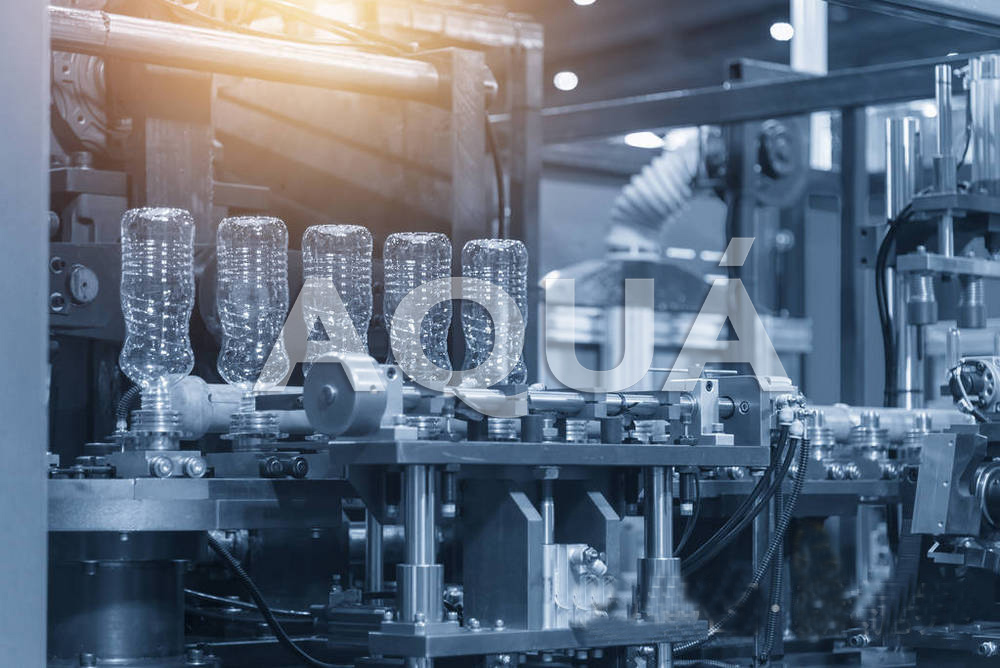

Fully automatic bottle blowing machine

1. It is a stable two-step blow-down stretch automatic blowing machine.

2. It can be used from 2 cavity to 9 cavity with a speed of 1000 bottles per hour (500 ml plastic bottles),max volume 2L Plastic bottle

3. It is suitable for blowing any kind of carbonated beverage bottle,sparkling beverage bottle,pure water bottle, mineral water bottle,fruit juice beverage bottle,cosmetic bottles,large diameter bottles, high temperature resistance bottles and other packaging bottles.

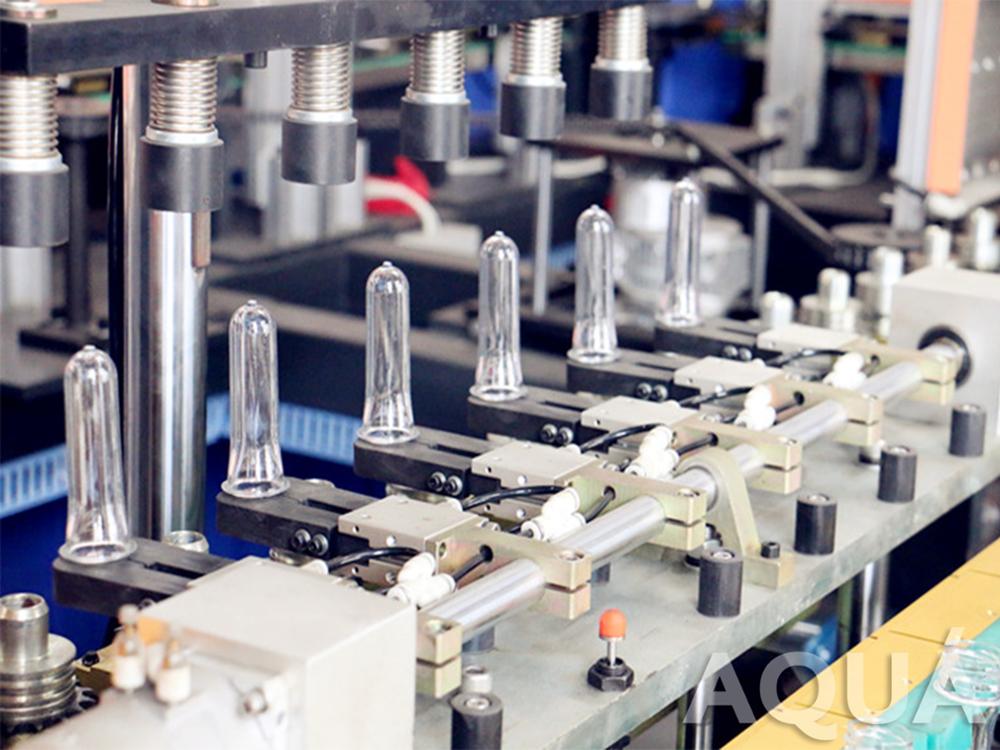

New Auto Preform Unscrambler System.

Adopts one-way preform-feeding structure and preform-separating by servo motor structure which solve the preform block and

abrasion problem.

There are two photoelectric sensors to control preform-loading motor and preform-separating cylinder that will warn the operator

to add the preforms into the hopper when lacks preform instead of stopping the machine.

abrasion problem.

There are two photoelectric sensors to control preform-loading motor and preform-separating cylinder that will warn the operator

to add the preforms into the hopper when lacks preform instead of stopping the machine.

New Heating System

Perfect heating system design decrease power consumption.

Special oven design helps power saving and easy maintain.

Each lamp position and temperature can be adjusted.

Cycle air-cooling system keeps the oven temperature constantly.

Special oven design helps power saving and easy maintain.

Each lamp position and temperature can be adjusted.

Cycle air-cooling system keeps the oven temperature constantly.

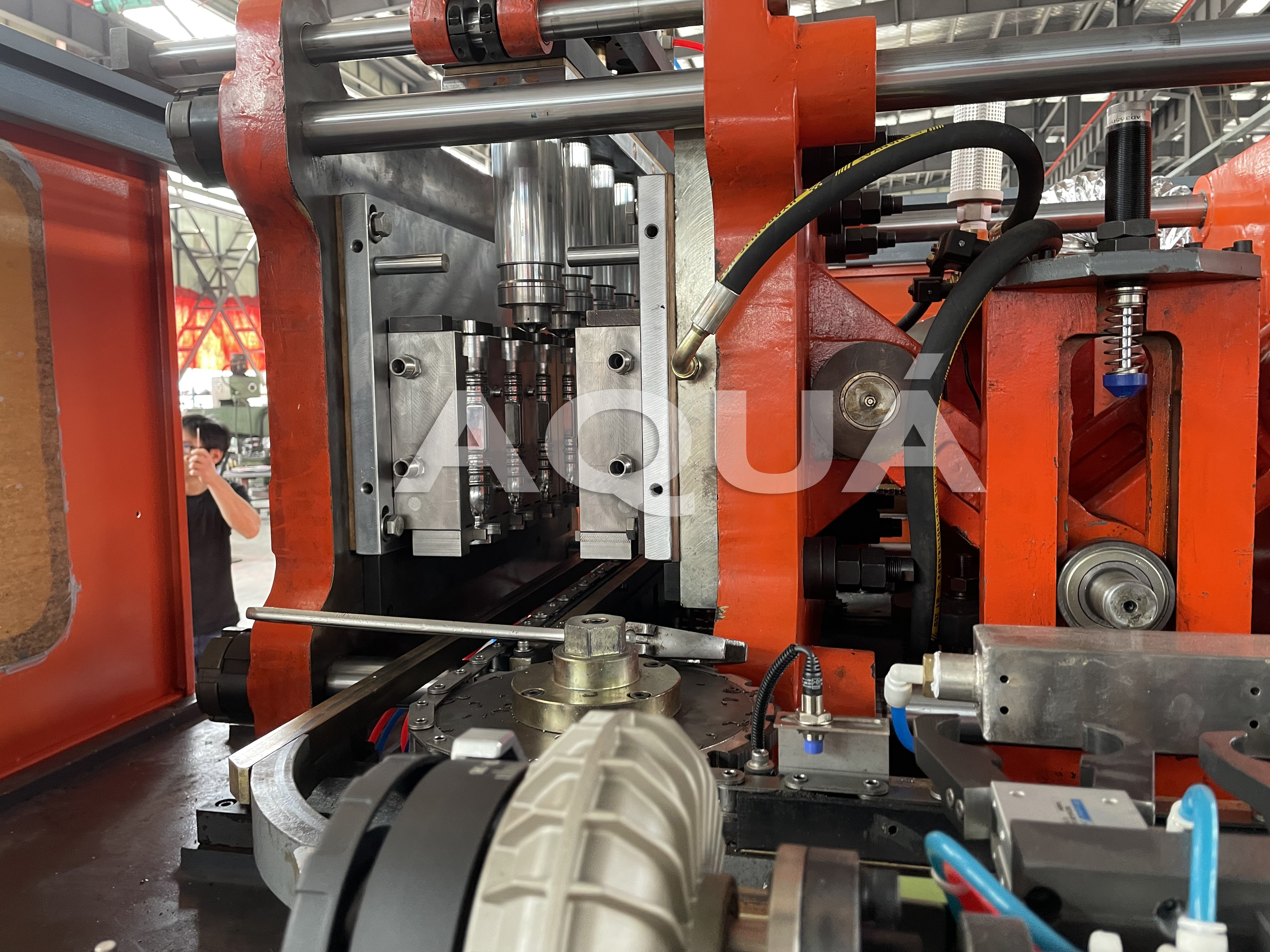

servo mold clamping system

Adopts servo motor to drive the two cranks to control the clamping system which can shorten the mold-clamping time and improve

productivity, and also solve the swelling mold and big joint line problem with the effect of pressurize plate.

Servo motor using for stretching to ensure the bottle blowing speed faster and more stable bottle quality.

productivity, and also solve the swelling mold and big joint line problem with the effect of pressurize plate.

Servo motor using for stretching to ensure the bottle blowing speed faster and more stable bottle quality.

Servo driving and cam linking blowing section:

The unique cam linking system integrates movement of mold-opening, mold-locking and bottom mold-elevating in one movement,

equipped with high speed servo driving system which greatly shorten the cycle of blowing and increase the capacity.

equipped with high speed servo driving system which greatly shorten the cycle of blowing and increase the capacity.

Intensive heating

Intensive heating is generally used in high-speed bottle blowing machines and the blowing of large-capacity bottles. The uniform and dense temperature zone can heat the preforms and increase the production speed of the equipment.

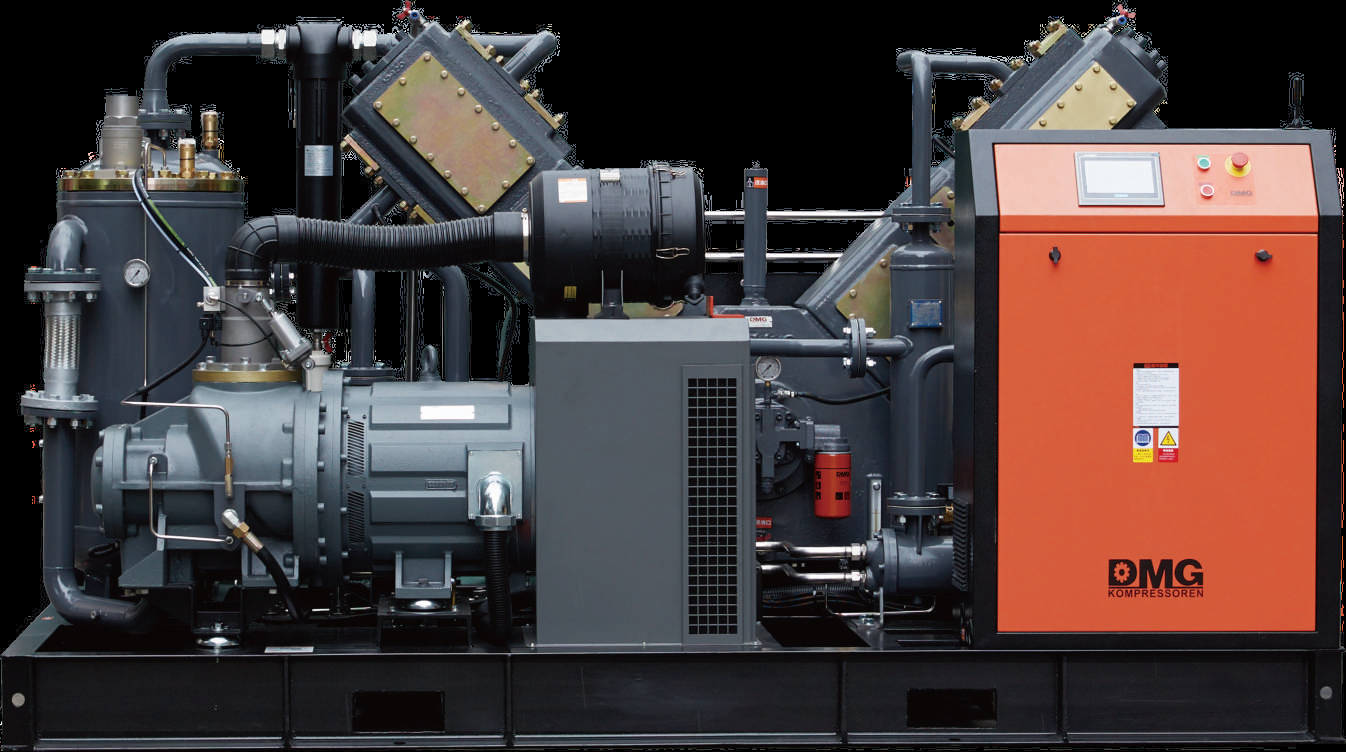

Air compressor

Air compress is very important part in the blowing system, it can supply air stable or not depends on the product quality, so we choose top supplier as our cooperator.

SHANGAIR and DMG Brand.

Semi automatic bottle blowing machine

1 Speed : 300-600pcs/h

2. Bottle volume 5L

PRODUCT SPECIFICATIONS

Parameters | Unit | AM 5L-1 |

Clamping Force | kg | 26000 |

Clamping Stroke | mm | 280 |

Stretching Stroke | mm | 450 |

Bottom stroke | mm | \ |

Cavity Spacing | mm | 90-120 |

Number of Cavity | Cavities | 1-2 |

Carriage Unit | pcs | 96 |

Theoretical output | bph | 300-400 |

Total Power | kw | 42 |

Healing Power | kw | 40*1KW=40 |

Number of Lamp Layers | Layers | 10 |

Operating Pressure | kg/cm2 | 7-9 |

Low Pressure Air Consumption | ltr/min | 600 |

Blowing Pressure | kg/cm2 | 20-30 |

High Pressure Air Consumption | ltr/min | 1600 |

Operating Pressure | kg/cm2 | 2-4 |

Temperature Range | ℃ | 10-12 |

Consumption | kcal/hr | 2000 |

Flow Rate | ltr/min | 200 |

Main Machine Dimensions | mm(L*W*H) | 1950*650*1750 |

Main Machine Weight | kg | 700 |

Preform Loader Dimensions | mm(L*W*H) | 2170 * 670*1600 |

Preform Loader Weight | kg | 400 |

Successful Project

Project in Ghana

Project in Armenia

Project in Canda

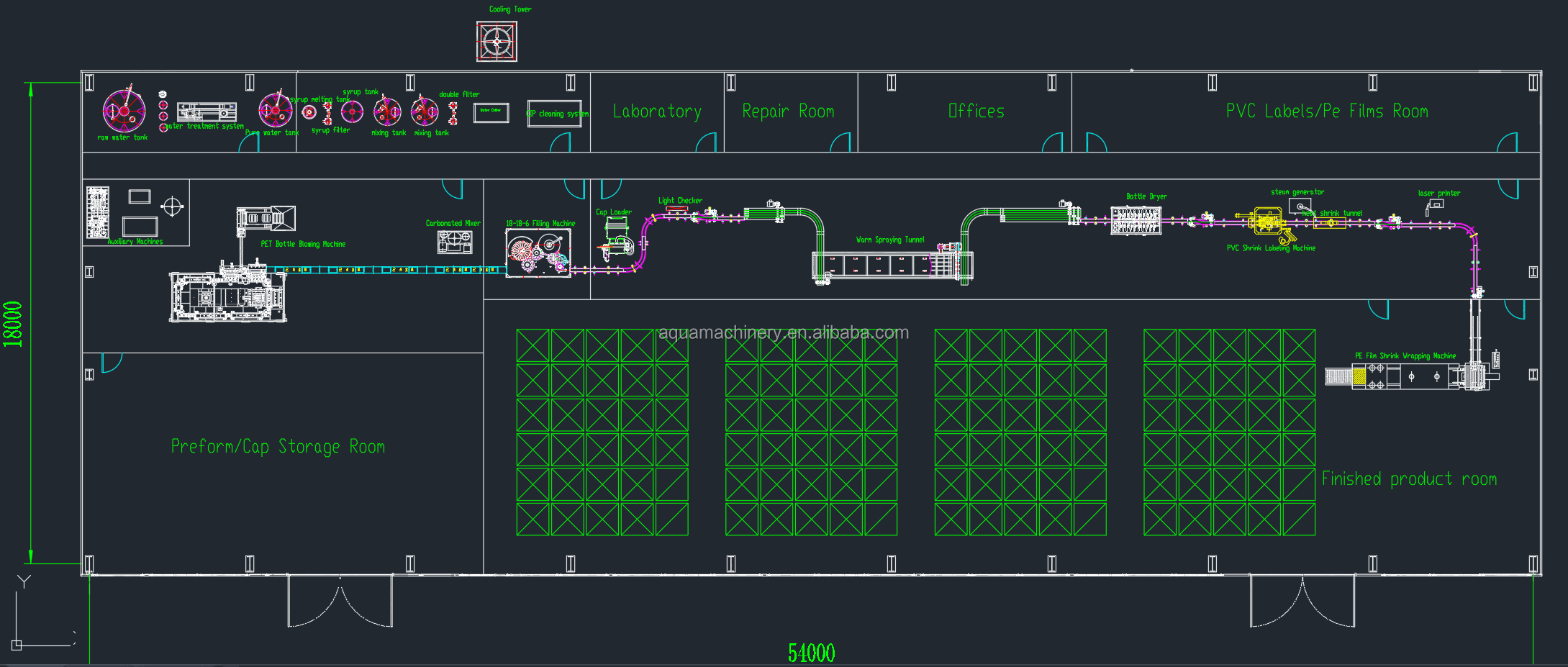

Complete Line Solution

Water Purification system

Used to filter water to be drinking Capacity : Depends on Customer's requirement ,8000LPH( as picture)

membrane brand : Dow Membrane

Material : SUS304

membrane brand : Dow Membrane

Material : SUS304

Depalletizer

Used for depalletizing various containers, such as cans, glass bottles, plastic bottles, etc.

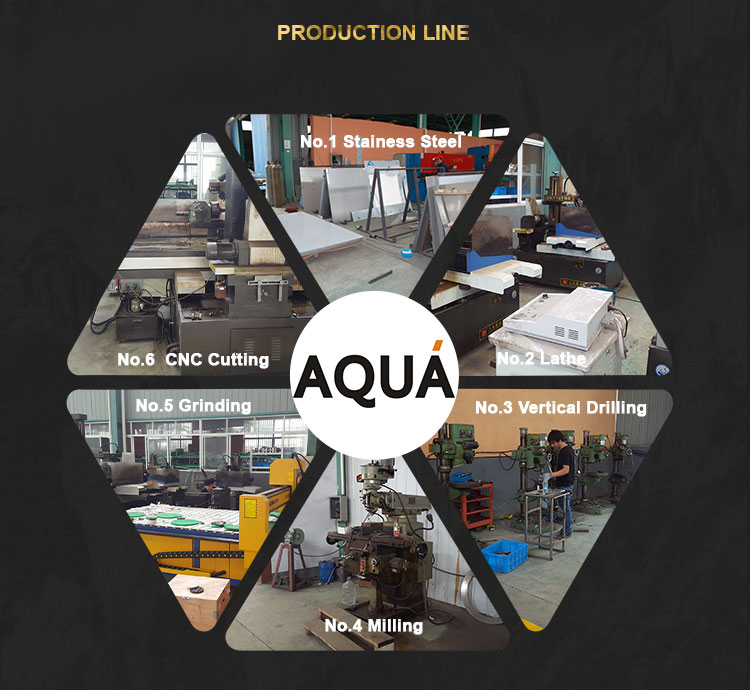

Our Factory

1 / Standardized workshop of total 20,000 square meters.

2 / The equipment will be tested and run for 24 hours before leaving the factory, to ensure the smooth working of water pipeline,

and pneumatic, electrical and mechanical stability.

3 / Sufficient stock of spare parts ensures the timely delivery and supply of spare parts.

Our Team

1 / Professional installation team who can speak fluent English can help customers make benefits in a shortest time.

2 / The engineers are experienced. We can produce different products with different capacity and work out reasonable flow chart a per customers' requirements to save space.

Certifications

We have been producing our goods with mature technique and first-class quality. Our products are not only marketed inland, but also exported to all over the world, Such as: Africa, Mid East, South Asia, South America. We believe

truthfulness,conscientiousness, enterprising spirit, continuous improvement and creativeness in running business, which helps our finest products enter the market.

1 / Standardized workshop of total 20,000 square meters.

2 / The equipment will be tested and run for 24 hours before leaving the factory, to ensure the smooth working of water pipeline,

and pneumatic, electrical and mechanical stability.

3 / Sufficient stock of spare parts ensures the timely delivery and supply of spare parts.

Our Team

1 / Professional installation team who can speak fluent English can help customers make benefits in a shortest time.

2 / The engineers are experienced. We can produce different products with different capacity and work out reasonable flow chart a per customers' requirements to save space.

Certifications

We have been producing our goods with mature technique and first-class quality. Our products are not only marketed inland, but also exported to all over the world, Such as: Africa, Mid East, South Asia, South America. We believe

truthfulness,conscientiousness, enterprising spirit, continuous improvement and creativeness in running business, which helps our finest products enter the market.

Our manufacturing factory

At present, we manufacture and provide the following lines to our customers:Beverage Filling Complete Line、water treatment plants、water filling machine、beverage filling machine、beverage preparation system、packages equipment coding machine、labeling machine、PE Film Shrink Wrapping Machine、Injection machine、Blow Molding Machine.We welcome distributors and factory owners from around the world to cooperate with us and look forward to receiving your inquiries in the near future.

Layout For Customer

Feedback From Customers

Product packaging

We have 2 kinds of Packaging way

1. Exported Wooden cases packaging

2. Wooden pallet ( Normally for big size machine )

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

● Each component before assembly needs strictly control by inspecting personnel.

● Each assembly is in charged by a master who has working experience for more than 5 years.

●After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory.

THE AFTER-SALE SERVICE

● After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools.

● After the commissioning, we will package the equipment by standard export package for shipment.

● According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

● Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the

customers' project.

HOW TO GUARANTEE YOUR FUNDS TO BE SAFE AND DELIVERY TO BE ON TIME?

● Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to buy.

● After the factory visit, You can ensure the facility of our bank account.

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME.

● If we can fulfill your request and you interested in our products, you may pay a visit to Our Machinery site.

● The meaning of visiting supplier, because seeing is believing, AQUA Machine with own manufacture and developed & research team,we can send you engineers and make sure your after sales service.

● Each component before assembly needs strictly control by inspecting personnel.

● Each assembly is in charged by a master who has working experience for more than 5 years.

●After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory.

THE AFTER-SALE SERVICE

● After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools.

● After the commissioning, we will package the equipment by standard export package for shipment.

● According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

● Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the

customers' project.

HOW TO GUARANTEE YOUR FUNDS TO BE SAFE AND DELIVERY TO BE ON TIME?

● Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to buy.

● After the factory visit, You can ensure the facility of our bank account.

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME.

● If we can fulfill your request and you interested in our products, you may pay a visit to Our Machinery site.

● The meaning of visiting supplier, because seeing is believing, AQUA Machine with own manufacture and developed & research team,we can send you engineers and make sure your after sales service.

Related Keywords

Related Keywords

You May Also Like

You May Also Like