Full Automatic PET Bottle Blowing Machine - 6000-12000pcs Stretch Type Plastic Blow Molding Machine

-

$4900.00≥1 set

- Min. Order:

- 1 set

- Min. Order:

- 1 set

Your message must be between 20 to 2000 characters

Contact Now

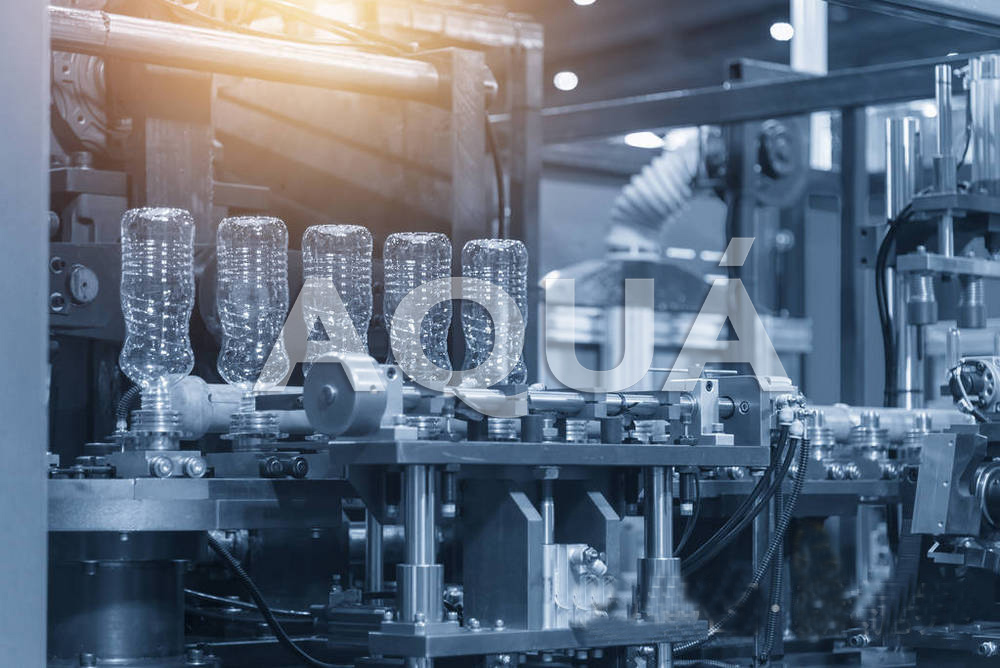

Full Automatic 6000-12000pcs PET Bottle Blowing Machine / Stretch Type Plastic Blow Molding Machine

1. It is used to make PET bottles

2. we have different capacity blowing machine from 600-14000pcs.h, tell me your requirement, so we can give the solution.

3. For 0.1-20L bottle size .

4. water bottle, carbonated bottle can use the same machine, juice machine will be different. so customers should be clear.

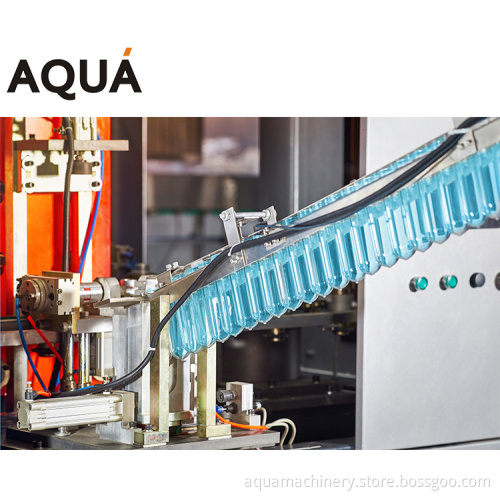

Recently we shipped a 7000bph bottle blowing machine, here share some pictures for reference

Main electic Component of our Full Automatic 6000-12000pcs PET Bottle Blowing Machine / Stretch Type Plastic Blow Molding Machine

|

Electrical components |

PLC |

Taiwan Delta |

Cylinders |

clamping cylinder |

SMC |

|

touch screen |

Taiwan Delta |

stretching cylinder |

SMC |

||

|

relay |

Schneider |

bottle-takeout flipping cylinder |

FEST0 |

||

|

circuit breaker |

Schneider |

first-stage slide cylinder |

SMC |

||

|

air switch |

Schneider |

second-stage slide cylinder |

SMC |

||

|

start button |

Schneider |

heating cylinder |

SMC |

||

|

two-position switch |

Schneider |

Preform-separating cylinder |

SMC |

||

|

scram button |

Schneider |

Manipulator cylinder |

SMC |

||

|

power supply |

Schneider |

Bottle die cylinder |

SMC |

||

|

proximity switch |

Schneider |

Valves |

high pressure blowing valve |

PARKER |

|

|

photoelectric switch |

Schneider |

high pressure exhaust valve |

PARKER |

||

|

Air Filtration |

low pressure oil-water separator |

FEST0

3 in 1 |

high pressure one-way valve |

FEST0 |

|

|

low pressurepress-regulating valve |

low pressure muffler |

SMC |

|||

|

low pressure lubricator |

high pressure muffler |

ALWITCO |

|||

Technicial Parameters of Full Automatic 6000-12000pcs PET Bottle Blowing Machine / Stretch Type Plastic Blow Molding Machine

|

Item |

Technical Parameters |

|

|

Product Specifications |

Max Volume |

1800ml |

|

Max.container diameter |

Φ105 |

|

|

Max Container Mouth diameter |

Φ18mm - 38mm |

|

|

Max.container diameter |

330mm |

|

|

Max. Preform height embryonic tube |

180mm |

|

|

Clamping stroke |

120mm |

|

|

Base mould stroke |

50mm |

|

|

Bottle Spacing |

114.3mm |

|

|

Standard thickness of mold |

220mm |

|

|

Capacity |

4000(500ml) |

|

|

Mould |

4 |

|

|

Heating Part |

Heating Unit |

5 |

|

Heating lamp laye |

9 |

|

|

Number of tubules |

80 |

|

|

Machine Power |

Voltage |

220/380V |

|

Frequency |

50/60Hz |

|

|

Power |

35kw/h |

|

|

Installed power |

75kw |

|

|

Air Source |

High pressure compressed air pressure |

25~30bar |

|

High pressure compressed air consumption |

3.0m3/min |

|

|

Water chiller |

Pressure |

3bar |

|

Chilled water yield |

5m3/h |

|

|

Weight |

Main machine \ Heating machine \ electric control box |

3.5T |

|

Machine Size |

Machine (L×W×H) |

4500mm×2200mm×2300mm |

|

Preform-loader(L×W×H) |

2000mmx1400mm×2500mm |

Related Keywords