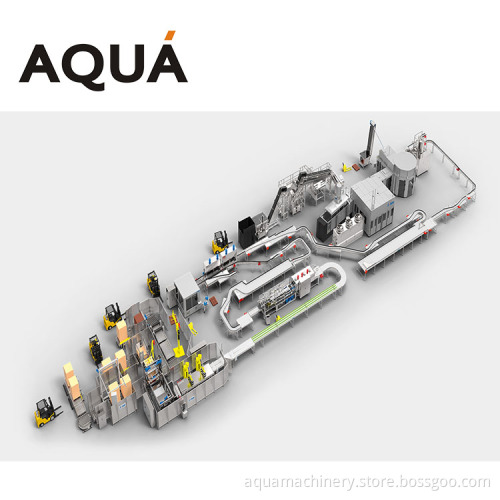

PET CSD Line Filling And Packaging Machine

-

$10000.00≥1 set

- Min. Order:

- 1 set

- Min. Order:

- 1 set

- Port:

- shanghai port

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 30 Set/Sets per Month pet csd filling line |

|---|---|

| Payment Type: | L/C,Western Union,T/T,MoneyGram |

| Port: | shanghai port |

PET CSD Line Filling And Packaging Machine Carbonated Drink Plant

1)This bottling machine is a unique design combining the three machines of bottle washing, filling and capping in one to decrease main power, to save space and to diminish the air pollution among the three machines.

(2)It is applicable for carbonated drink filled in plastic bottles and capped with plastic caps, with optional capacity from 2000BPH to 28000BPH.

(3)It is easy to change the shape of bottles, which can be done by changing the thumb wheel without adjusting the height of the machine.

(4)Adopting suspensory transmission gear can easily upkeep and be repaired.

(5)The machine case and the parts contacting with the materials are made of stainless steel which ensures the good external look and easy washing.

(6)It uses frequency changer to conrtol the main machine motor. And it has an output number indicating function which is easy to control the adjustment of the output.

- Rinser / filler / capper monobloc

- Bottle material: PET, glass, metal

- Bottle volume: 150ml - 2.5L

- Production capacity: 1000 - 18,000bottles/h

- Can design according to customers' demands

- We can supply filling line solution and filling machines for soft drinks (carbonated drinks)

Water Treatment System

According to customer's water source analysis report and the final water standard required ,we will suggest customer to choose the suitable water treatment plants.

Carbonated Drinks Pre Processing System

Carbonated beverage mixing system structure reasonable, =mix precision is high, CO2 mixes fully, has two times of cooling, two carbonation merits. Mainly is suitable for kinds of carbonated drink's mix processing, also may use in the paste drink, the fermentation drink and so on other soft drinks' mix processing.

Rinser Filler Capper Machine

Main Features

*Using the wind sent access and move wheel in the bottle directly connected technology; canceled screw and conveyor chains, this enable the change the bottle-shaped become easier.

* Bottles transmission adopt clip bottleneck technology, bottle-shaped transform not need to adjust the equipment level, only change related the curved plate, wheel and nylon parts is enough..

* The specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of bottle mouth to avoid secondary pollution.

*High-speed large Isobaric filling valve, filling fast, filling accurate and no liquid lose.

*Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

*Host adopt advanced PLC automatic control technology, the key electrical components from famous company such as Japan's Mitsubishi, France Schneider, OMRON.

Labeling And Packing Machine

As customer request and market demand ,we provide the better solution for the final product package ,

We have various kinds of options .Labeling machine have the PVC sleeve label ,BOPP hot glue label,Adhesive stick label ,Wet glue label ,and packing machine have the film shrink machine and carton box package.

Bottle Blowing Machine

This machine is a fully automatic, high intelligent, stable and reliable blowing machine, with simple structure, and low energy consumption. It is very popular and well used in food, beverages, cosmetics, pharmaceutical industry.

Related Keywords