MK-400 Automatic Chocolate Depositing Line

- Delivery Time:

- 30 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Jiangsu, China (Mainland) |

|---|

Product Description

Product Description

Product Description MSJZ Automatic Chocolate depositing line

This chocolate depositing line can automatically warm-up the mould, depositing and vibrating, it is suitable for depositing a lot of geometric chocolate, two colors, center filling, chocolate with granular nuts, it is adaptable and convenient operation. BASIC SPECIFICATION:

Chocolate depositing machine

In this automatic chocolate moulding equipment can produce following types of chocolate:

In this automatic chocolate moulding equipment can produce following types of chocolate:

pure chocolate

center filling chocolate

two color chocolate

three color chocolate

Cereal bar chocolate

Hollow chocolate

Chips chocolate

nuts mixed chocolate (nuts feeder unit required)

Chocolate cooling tunnel

Chocolate cooling tunnel  Export container

Export container  Customer visit Maike chocolate machine factory:

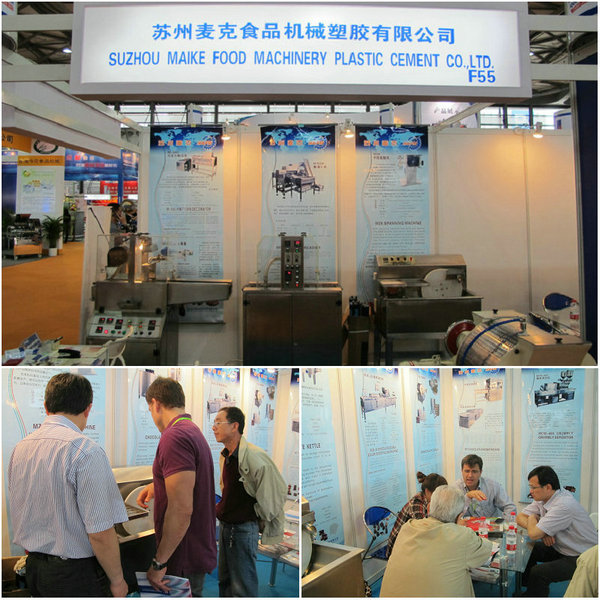

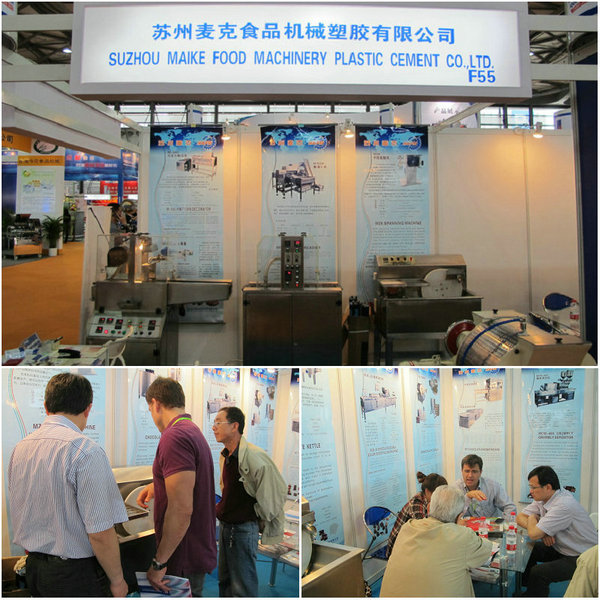

Customer visit Maike chocolate machine factory:  Maike chocolate machinery factory exhibition:

Maike chocolate machinery factory exhibition:

Our Services Emergency Repairs

Our Services Emergency Repairs

Preventative Maintenance

Full Reconditioning

OEM service Company Information Chocolate → Chocolate paste

Pure cocoa butter

Material: cocoa liquid,cocoa butter, cocoa powder ,sugar ,milk powder

Flowchart : material → melting machine & sugar pulverizer → conching machine → temper → refining tank → pump → forming machine.

Cocoa butter replacer

Material: cocoa liquid,cocoa butter replacer , cocoa powder ,sugar ,milk powder

Flowchart: material → melting& sugar pulverizer → conching / ball milling machine → temper → pump → forming machine

Chocolate paste → Finished chocolate

1. Chocolate bar line: chocolate temper → chocolate pouring machine → cooling tunnel

2. Golden coin chocolate line : chocolate temper → chocolate pouring → cooling tunnel → chocolate coin machine → chocolate embossing

3. Chocolate beans line : temper → chocolate bean forming machine → chocolate polishing machine.

4. MYLIKES chocolate : mixer → MYLIKES core forming machine → bake room → temper → chocolate polishing machine

5. Cereal chocolate line: temper → cereal( crispy rice) chocolate forming machine → cooling tunnel

6. Balls nuts chocolate line (Hazelnuts,Ferrero Rocher) : temper → enrober machine → sprinkled nuts machine → cooling tunnel → temper → enrober machine → cooling tunnel

7. Chocolate enrober line ( biscuit,cake) : temper → enrober machine → cooling tunnel

8. Decorator chocolate line: temper →enrober machine → chocolate decorator pattern machine → cooling tunnel

9. Rock chocolate line: temper → chocolate depositor → cooling tunnel → rock stone cutter machine → chocolate polishing

10. Hollow chocolate line : temper → chocolate pouring → hollow spinning forming → cooling tunnel

This chocolate depositing line can automatically warm-up the mould, depositing and vibrating, it is suitable for depositing a lot of geometric chocolate, two colors, center filling, chocolate with granular nuts, it is adaptable and convenient operation. BASIC SPECIFICATION:

PLC controlled stepper motor | 125-5000r/min |

Capacity | 12-20 moulds/min |

Working pressure | 0.6Mpa-0.8Mpa |

Vibration frequency | 2940R/MIN, 220V 0.30KW |

Temperature for warm-up mould | 35-45C |

Water tank heating-up temperature | 55-60C |

Rotation driving cylinder of depositing | φ63*50 2pcs |

Driving cylinder of depositing plunger | φ100*100 2pcs |

Driving cylinder of stripping | φ50*50 total 1pc |

Plastic mould dimension | 275*175*25mm |

Installed capacity | 6KW |

Main machine | 0.75KW-110BYG350B |

Mould warm-up power | 0.4KW*4=1.6KW |

Water tank heater | 3KW -380V |

Machine dimension | 4200*520*1450MM |

Machine weight | 420kg |

In this automatic chocolate moulding equipment can produce following types of chocolate:

In this automatic chocolate moulding equipment can produce following types of chocolate:pure chocolate

center filling chocolate

two color chocolate

three color chocolate

Cereal bar chocolate

Hollow chocolate

Chips chocolate

nuts mixed chocolate (nuts feeder unit required)

Chocolate cooling tunnel

Chocolate cooling tunnel  Export container

Export container  Customer visit Maike chocolate machine factory:

Customer visit Maike chocolate machine factory:  Maike chocolate machinery factory exhibition:

Maike chocolate machinery factory exhibition: Our Services Emergency Repairs

Our Services Emergency RepairsPreventative Maintenance

Full Reconditioning

OEM service Company Information Chocolate → Chocolate paste

Pure cocoa butter

Material: cocoa liquid,cocoa butter, cocoa powder ,sugar ,milk powder

Flowchart : material → melting machine & sugar pulverizer → conching machine → temper → refining tank → pump → forming machine.

Cocoa butter replacer

Material: cocoa liquid,cocoa butter replacer , cocoa powder ,sugar ,milk powder

Flowchart: material → melting& sugar pulverizer → conching / ball milling machine → temper → pump → forming machine

Chocolate paste → Finished chocolate

1. Chocolate bar line: chocolate temper → chocolate pouring machine → cooling tunnel

2. Golden coin chocolate line : chocolate temper → chocolate pouring → cooling tunnel → chocolate coin machine → chocolate embossing

3. Chocolate beans line : temper → chocolate bean forming machine → chocolate polishing machine.

4. MYLIKES chocolate : mixer → MYLIKES core forming machine → bake room → temper → chocolate polishing machine

5. Cereal chocolate line: temper → cereal( crispy rice) chocolate forming machine → cooling tunnel

6. Balls nuts chocolate line (Hazelnuts,Ferrero Rocher) : temper → enrober machine → sprinkled nuts machine → cooling tunnel → temper → enrober machine → cooling tunnel

7. Chocolate enrober line ( biscuit,cake) : temper → enrober machine → cooling tunnel

8. Decorator chocolate line: temper →enrober machine → chocolate decorator pattern machine → cooling tunnel

9. Rock chocolate line: temper → chocolate depositor → cooling tunnel → rock stone cutter machine → chocolate polishing

10. Hollow chocolate line : temper → chocolate pouring → hollow spinning forming → cooling tunnel

Related Keywords

Related Keywords