Cream Sandwiched Chocolate Machine

- Delivery Time:

- 30 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Jiangsu, China (Mainland) |

|---|

Product Description

Product Description

Specifications 1.Cream sandwiched chocolate machine.

2.Chocolate Depositing and vibrating.

3.Chocolate with granular nuts.

Product Description MSJZ Chocolate Sandwiched depositing machine

This machine is advanced equipment with mulltiple functions for the pouring and molding of includes roasting the mold, molding ,vibration,scratching,mold-turning,cooling,striping the mold, and convey, The PLC automatic control is adopted in the device. its can make compound chocolate,pure fat chocolate and sandwich choclate etc. the manner of pouring consiste single action and double action. therefore, this device is the idea equipment for all distrbutors.

Chocolate cooling tunnel  Feel free to contact us!

Feel free to contact us!  Export container

Export container  Customer visit Maike chocolate machine factory:

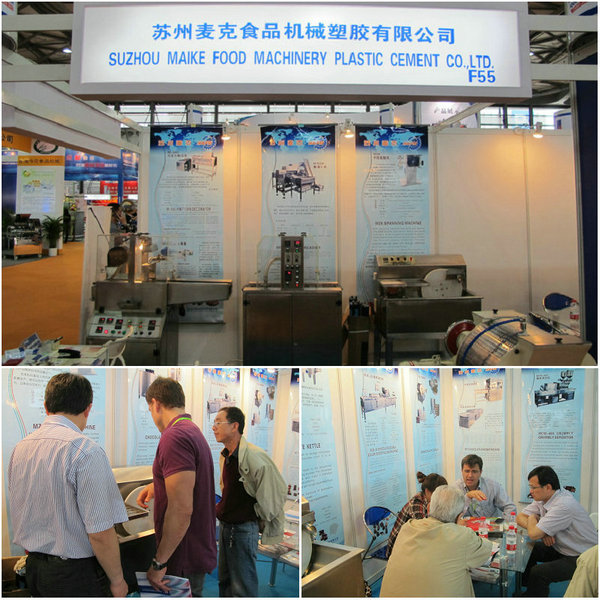

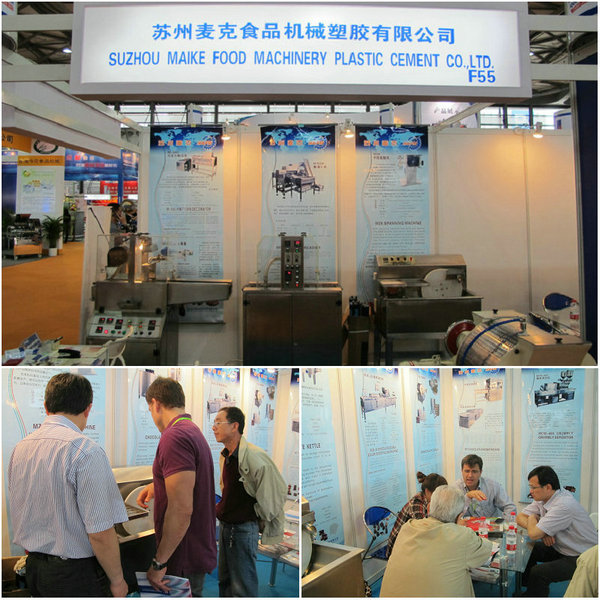

Customer visit Maike chocolate machine factory:  Maike chocolate machinery factory exhibition:

Maike chocolate machinery factory exhibition:

Our Services Emergency Repairs

Our Services Emergency Repairs

Preventative Maintenance

Full Reconditioning

OEM service Company Information Chocolate → Chocolate paste

Pure cocoa butter

Material: cocoa liquid,cocoa butter, cocoa powder ,sugar ,milk powder

Flowchart : material → melting machine & sugar pulverizer → conching machine → temper → refining tank → pump → forming machine.

Cocoa butter replacer

Material: cocoa liquid,cocoa butter replacer , cocoa powder ,sugar ,milk powder

Flowchart: material → melting& sugar pulverizer → conching / ball milling machine → temper → pump → forming machine

Chocolate paste → Finished chocolate

1. Chocolate bar line: chocolate temper → chocolate pouring machine → cooling tunnel

2. Golden coin chocolate line : chocolate temper → chocolate pouring → cooling tunnel → chocolate coin machine → chocolate embossing

3. Chocolate beans line : temper → chocolate bean forming machine → chocolate polishing machine.

4. MYLIKES chocolate : mixer → MYLIKES core forming machine → bake room → temper → chocolate polishing machine

5. Cereal chocolate line: temper → cereal( crispy rice) chocolate forming machine → cooling tunnel

6. Balls nuts chocolate line (Hazelnuts,Ferrero Rocher) : temper → enrober machine → sprinkled nuts machine → cooling tunnel → temper → enrober machine → cooling tunnel

7. Chocolate enrober line ( biscuit,cake) : temper → enrober machine → cooling tunnel

8. Decorator chocolate line: temper →enrober machine → chocolate decorator pattern machine → cooling tunnel

9. Rock chocolate line: temper → chocolate depositor → cooling tunnel → rock stone cutter machine → chocolate polishing

10. Hollow chocolate line : temper → chocolate pouring → hollow spinning forming → cooling tunnel

2.Chocolate Depositing and vibrating.

3.Chocolate with granular nuts.

Product Description MSJZ Chocolate Sandwiched depositing machine

This machine is advanced equipment with mulltiple functions for the pouring and molding of includes roasting the mold, molding ,vibration,scratching,mold-turning,cooling,striping the mold, and convey, The PLC automatic control is adopted in the device. its can make compound chocolate,pure fat chocolate and sandwich choclate etc. the manner of pouring consiste single action and double action. therefore, this device is the idea equipment for all distrbutors.

parameter | 340 three-step synthesis |

production pacity | 1.5-3 T/shifts |

rated molding | 18-25 Times/min |

shaped of chocolate | the customers can make their choices according to their actural needs |

power supply voltage | 380v |

power | 43kw |

Compressed amount of use | 0.5/min |

compressed preesure | 0.4Mpa |

temperature of the applicable envirroment | 20-25 |

freezing capaicty | 21000kcal/h |

tempreture of the cooling tunnel | 5-10 °C |

Weight of chocolate pure chocolate | 0-600g |

weight of chooclate sandwiching chocolate | 50% |

weight of the machine | 10000kg |

Machine measure LX W X H ,meter | 26.3 X 1.2 X 2.2 |

size of the mold L X W X H,meter | 320X 220X 32. 510X 200X 32 |

Amount of molds | 206 (PCS) |

Feel free to contact us!

Feel free to contact us!  Export container

Export container  Customer visit Maike chocolate machine factory:

Customer visit Maike chocolate machine factory:  Maike chocolate machinery factory exhibition:

Maike chocolate machinery factory exhibition: Our Services Emergency Repairs

Our Services Emergency RepairsPreventative Maintenance

Full Reconditioning

OEM service Company Information Chocolate → Chocolate paste

Pure cocoa butter

Material: cocoa liquid,cocoa butter, cocoa powder ,sugar ,milk powder

Flowchart : material → melting machine & sugar pulverizer → conching machine → temper → refining tank → pump → forming machine.

Cocoa butter replacer

Material: cocoa liquid,cocoa butter replacer , cocoa powder ,sugar ,milk powder

Flowchart: material → melting& sugar pulverizer → conching / ball milling machine → temper → pump → forming machine

Chocolate paste → Finished chocolate

1. Chocolate bar line: chocolate temper → chocolate pouring machine → cooling tunnel

2. Golden coin chocolate line : chocolate temper → chocolate pouring → cooling tunnel → chocolate coin machine → chocolate embossing

3. Chocolate beans line : temper → chocolate bean forming machine → chocolate polishing machine.

4. MYLIKES chocolate : mixer → MYLIKES core forming machine → bake room → temper → chocolate polishing machine

5. Cereal chocolate line: temper → cereal( crispy rice) chocolate forming machine → cooling tunnel

6. Balls nuts chocolate line (Hazelnuts,Ferrero Rocher) : temper → enrober machine → sprinkled nuts machine → cooling tunnel → temper → enrober machine → cooling tunnel

7. Chocolate enrober line ( biscuit,cake) : temper → enrober machine → cooling tunnel

8. Decorator chocolate line: temper →enrober machine → chocolate decorator pattern machine → cooling tunnel

9. Rock chocolate line: temper → chocolate depositor → cooling tunnel → rock stone cutter machine → chocolate polishing

10. Hollow chocolate line : temper → chocolate pouring → hollow spinning forming → cooling tunnel

Related Keywords

Related Keywords