chocolate teeming molding line

- Delivery Time:

- 30 Days

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Jiangsu, China (Mainland) |

|---|

2.Chocolate moulding and vibrating.

3.Chocolate with granular nuts.

Youtube video link : //youtu.be/EsUTylr3Zoc chocolate moulding machine Product Description MSJZ Chocolate teeming Moulding machine

This chocolate moulding machine can automatically warm-up the mould, depositing and vibrating, it is suitable for depositing a lot of geometric chocolate, two colors, center filling, chocolate with granular nuts, it is adaptable and convenient operation. BASIC SPECIFICATION:

PLC controlled stepper motor | 125-5000r/min |

Capacity | 12-20 moulds/min |

Working pressure | 0.6Mpa-0.8Mpa |

Vibration frequency | 2940R/MIN, 220V 0.30KW |

Temperature for warm-up mould | 35-45C |

Water tank heating-up temperature | 55-60C |

Rotation driving cylinder of depositing | φ63*50 2pcs |

Driving cylinder of depositing plunger | φ100*100 2pcs |

Driving cylinder of stripping | φ50*50 total 1pc |

Plastic mould dimension | 275*175*25mm |

Installed capacity | 6KW |

Main machine | 0.75KW-110BYG350B |

Mould warm-up power | 0.4KW*4=1.6KW |

Water tank heater | 3KW -380V |

Machine dimension | 4200*520*1450MM |

Machine weight | 420kg |

Chocolate creal bar moulding machine

Chocolate creal bar moulding machine  Chocolate chips moulding machine

Chocolate chips moulding machine  Chocolate cooling tunnel

Chocolate cooling tunnel  MQF-I Manual Chocolate Moulding Tempering Machine 1.This chocolate moulding machine consists of pouring, auto temperature control and vibration system; it is quite flexible and has compact structure. 2.It is very suitable for small chocolate shops, family workshop. BASIC SPECIFICATION:

MQF-I Manual Chocolate Moulding Tempering Machine 1.This chocolate moulding machine consists of pouring, auto temperature control and vibration system; it is quite flexible and has compact structure. 2.It is very suitable for small chocolate shops, family workshop. BASIC SPECIFICATION: Effective volume | 30L |

Electric heating | 0.5KW |

Vibrating table | 0.02KW |

Main motor power | 0.75KW |

Rotation speed | 28R/MIN |

Weight | 120KG |

Dimension | 1135X755X1030MM |

Export container

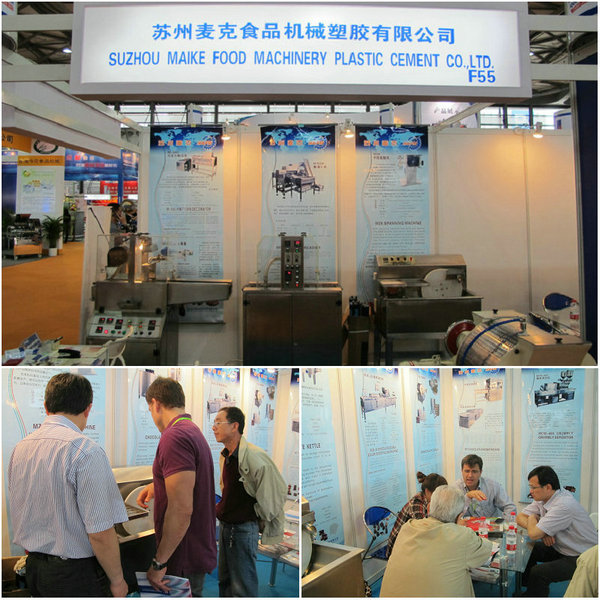

Export container  Customer visit Maike chocolate machine factory:

Customer visit Maike chocolate machine factory:  Maike chocolate machinery factory exhibition:

Maike chocolate machinery factory exhibition: Our Services Emergency Repairs

Our Services Emergency RepairsPreventative Maintenance

Full Reconditioning

OEM service Company Information Chocolate → Chocolate paste

Pure cocoa butter

Material: cocoa liquid,cocoa butter, cocoa powder ,sugar ,milk powder

Flowchart : material → melting machine & sugar pulverizer → conching machine → temper → refining tank → pump → forming machine.

Cocoa butter replacer

Material: cocoa liquid,cocoa butter replacer , cocoa powder ,sugar ,milk powder

Flowchart: material → melting& sugar pulverizer → conching / ball milling machine → temper → pump → forming machine

Chocolate paste → Finished chocolate

1. Chocolate bar line: chocolate temper → chocolate pouring machine → cooling tunnel

2. Golden coin chocolate line : chocolate temper → chocolate pouring → cooling tunnel → chocolate coin machine → chocolate embossing

3. Chocolate beans line : temper → chocolate bean forming machine → chocolate polishing machine.

4. MYLIKES chocolate : mixer → MYLIKES core forming machine → bake room → temper → chocolate polishing machine

5. Cereal chocolate line: temper → cereal( crispy rice) chocolate forming machine → cooling tunnel

6. Balls nuts chocolate line (Hazelnuts,Ferrero Rocher) : temper → enrober machine → sprinkled nuts machine → cooling tunnel → temper → enrober machine → cooling tunnel

7. Chocolate enrober line ( biscuit,cake) : temper → enrober machine → cooling tunnel

8. Decorator chocolate line: temper →enrober machine → chocolate decorator pattern machine → cooling tunnel

9. Rock chocolate line: temper → chocolate depositor → cooling tunnel → rock stone cutter machine → chocolate polishing

10. Hollow chocolate line : temper → chocolate pouring → hollow spinning forming → cooling tunnel

Related Keywords