maquina moldeadora de chocolate (enrobing machine)

- Delivery Time:

- 30 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Jiangsu, China (Mainland) |

|---|

Product Description

Product Description

Specifications 1.chocolate machine,enrobing.

2.Chocolate conching

3.Chocolate depositor machine,enrobing,wrapping

Product Description MTY Chocolate Enrobing Machine This chocolate enrobing machine is used to enrobe chocolate material on surfaces of various kinds of foods, such as puffed foods, nuts, all kinds of fondant materials, spherical and abnormal candies, cakes and biscuits, etc. Effective working width from 200 to 1200mm, different models can be customized as requirements. BASIC SPECIFIATION:

MJM-1000 CHOCOLATE CONCHE MACHINE It is the basic machine to grind chocolate material, as well as oil-bearing material, fluidness and some chemical raw material.

This machine adopts the worm wheel and worm screw driving system, the places contacting with food and the machine outer case are made of excellent alloy steel and stainless steel material. This machine is hand wheel operation with multi functions of grinding, dehydration, deodorization, dilution and emulsification. It is ideal equipment for chocolate production. MZF-60 Automatic Tempering Chocolate Machine 1.This chocolate machine is tempered via cooling water. It’s the key equipment in tempering process for high quality chocolate. 2.Differ from electric heating tempering machine, this machine has a cooling system attachment, tempering can be continuous. 3.Voltage is not a problem, we can make it as buyer's requirement, different capacities also can be done according to customers. CHOCOLATE MACHINE BASIC SPECIFICATION:

MQZ AUTOMATIC CHOCOLATE DEPOSITOR This machine is advanced equipment with multi-functions such as pouring, molding. It integrates the mechanism and electrical control. Whole production flow includes mold roasting, molding, vibrating, scratching, mold-turning, cooling, striping and conveying. PLC automatic control is adopted in this device, it can make compound chocolate, pure fat chocolate and sandwich chocolate etc., and pouring methods have single and double actions. Chocolate → Chocolate paste

Pure cocoa butter

Material: cocoa liquid,cocoa butter, cocoa powder ,sugar ,milk powder

Flowchart : material → melting machine & sugar pulverizer → conching machine → temper → refining tank → pump → forming machine.

Cocoa butter replacer

Material: cocoa liquid,cocoa butter replacer , cocoa powder ,sugar ,milk powder

Flowchart: material → melting& sugar pulverizer → conching / ball milling machine → temper → pump → forming machine

Chocolate paste → Finished chocolate

1. Chocolate bar line: chocolate temper → chocolate pouring machine → cooling tunnel

2. Golden coin chocolate line : chocolate temper → chocolate pouring → cooling tunnel → chocolate coin machine → chocolate embossing

3. Chocolate beans line : temper → chocolate bean forming machine → chocolate polishing machine.

4. MYLIKES chocolate : mixer → MYLIKES core forming machine → bake room → temper → chocolate polishing machine

5. Cereal chocolate line: temper → cereal( crispy rice) chocolate forming machine → cooling tunnel

6. Balls nuts chocolate line (Hazelnuts,Ferrero Rocher) : temper → enrober machine → sprinkled nuts machine → cooling tunnel → temper → enrober machine → cooling tunnel

7. Chocolate enrober line ( biscuit,cake) : temper → enrober machine → cooling tunnel

8. Decorator chocolate line: temper →enrober machine → chocolate decorator pattern machine → cooling tunnel

9. Rock chocolate line: temper → chocolate depositor → cooling tunnel → rock stone cutter machine → chocolate polishing

10. Hollow chocolate line : temper → chocolate pouring → hollow spinning forming → cooling tunnel

Main chocolate machine pictures:

our workshop:

our workshop:

Company Information Welcome to our official site: www.szmkjx.com

Company Information Welcome to our official site: www.szmkjx.com

chocolate machine: conching,milling ball,tempering,melting,holding,filling,mixing,forming,depositor,enrobing,coating,cooling tunnel,packing machine.

Chocolate production line: moulding line,chocoalte paste line,chocolate bean line,chocolate egg line,stone chocolate line,truffle chocolate line, cereal chocolate line,mylike chocolate line,chocolate chips/drops line,chocolate bar line,chocolate nuts line.

Our Services All the above mentioned chocolate equipments are manufactured under the management of international quality criteria UKAS ISO-9001:2008. The main machines are with CE licenses

and operation manual. Any quality problem, which belongs to the manufacture responsibility, will be offered free after-sales service for a year. All the products are standard pass quality. FAQ The purchaser offers the flat drawing of the workroom. The supplier should provide the relative technology for the chocolate equipments; the power source arrangement, the technology and the layout designing service. Packaging & Shipping The chocolate production equipments, aux. packed with PE/PP film in inner. outside by standard export woodcase. In shanghai port loading machine.

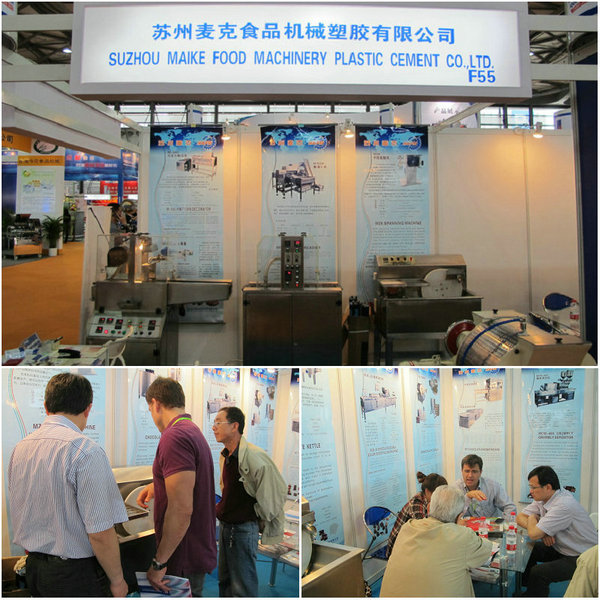

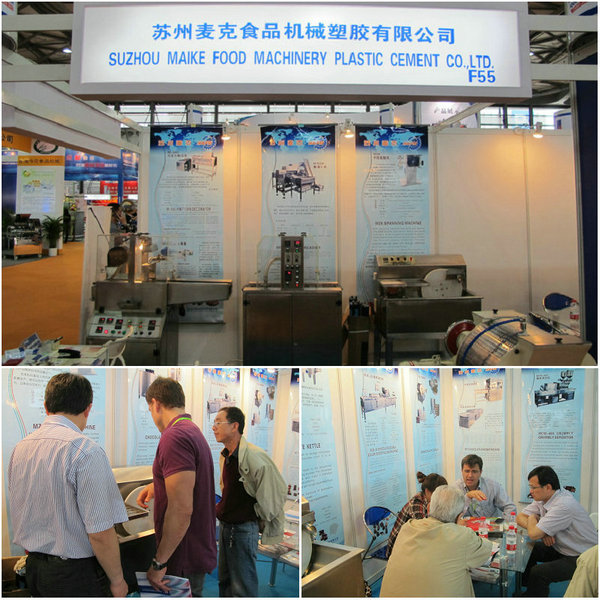

Customer visit: Exhibition:

Exhibition:

2.Chocolate conching

3.Chocolate depositor machine,enrobing,wrapping

Product Description MTY Chocolate Enrobing Machine This chocolate enrobing machine is used to enrobe chocolate material on surfaces of various kinds of foods, such as puffed foods, nuts, all kinds of fondant materials, spherical and abnormal candies, cakes and biscuits, etc. Effective working width from 200 to 1200mm, different models can be customized as requirements. BASIC SPECIFIATION:

Model | MTY-600 |

width of S.S. mesh belt | 600MM |

Chocolate waterfall | 550mm |

total power | 15.5KW |

weight | 600kg |

dimension(M) | 16.5*1.1*1.7 |

Wood case size | 2x1.4x1.67Meter |

This machine adopts the worm wheel and worm screw driving system, the places contacting with food and the machine outer case are made of excellent alloy steel and stainless steel material. This machine is hand wheel operation with multi functions of grinding, dehydration, deodorization, dilution and emulsification. It is ideal equipment for chocolate production. MZF-60 Automatic Tempering Chocolate Machine 1.This chocolate machine is tempered via cooling water. It’s the key equipment in tempering process for high quality chocolate. 2.Differ from electric heating tempering machine, this machine has a cooling system attachment, tempering can be continuous. 3.Voltage is not a problem, we can make it as buyer's requirement, different capacities also can be done according to customers. CHOCOLATE MACHINE BASIC SPECIFICATION:

Effective volume | 60L |

Main motor power | 1.1KW |

Vibrating motor | 25W |

Electric heating | 2KW for chocolate tank 24v-40w*4 for vibrating screen |

Chocolate transfer pump | 1.1KW |

Capacity | 180-200KG/H |

Dimension | 950*650*1700MM |

Weight | 250KG |

Pure cocoa butter

Material: cocoa liquid,cocoa butter, cocoa powder ,sugar ,milk powder

Flowchart : material → melting machine & sugar pulverizer → conching machine → temper → refining tank → pump → forming machine.

Cocoa butter replacer

Material: cocoa liquid,cocoa butter replacer , cocoa powder ,sugar ,milk powder

Flowchart: material → melting& sugar pulverizer → conching / ball milling machine → temper → pump → forming machine

Chocolate paste → Finished chocolate

1. Chocolate bar line: chocolate temper → chocolate pouring machine → cooling tunnel

2. Golden coin chocolate line : chocolate temper → chocolate pouring → cooling tunnel → chocolate coin machine → chocolate embossing

3. Chocolate beans line : temper → chocolate bean forming machine → chocolate polishing machine.

4. MYLIKES chocolate : mixer → MYLIKES core forming machine → bake room → temper → chocolate polishing machine

5. Cereal chocolate line: temper → cereal( crispy rice) chocolate forming machine → cooling tunnel

6. Balls nuts chocolate line (Hazelnuts,Ferrero Rocher) : temper → enrober machine → sprinkled nuts machine → cooling tunnel → temper → enrober machine → cooling tunnel

7. Chocolate enrober line ( biscuit,cake) : temper → enrober machine → cooling tunnel

8. Decorator chocolate line: temper →enrober machine → chocolate decorator pattern machine → cooling tunnel

9. Rock chocolate line: temper → chocolate depositor → cooling tunnel → rock stone cutter machine → chocolate polishing

10. Hollow chocolate line : temper → chocolate pouring → hollow spinning forming → cooling tunnel

Main chocolate machine pictures:

our workshop:

our workshop:

Company Information Welcome to our official site: www.szmkjx.com

Company Information Welcome to our official site: www.szmkjx.comchocolate machine: conching,milling ball,tempering,melting,holding,filling,mixing,forming,depositor,enrobing,coating,cooling tunnel,packing machine.

Chocolate production line: moulding line,chocoalte paste line,chocolate bean line,chocolate egg line,stone chocolate line,truffle chocolate line, cereal chocolate line,mylike chocolate line,chocolate chips/drops line,chocolate bar line,chocolate nuts line.

Our Services All the above mentioned chocolate equipments are manufactured under the management of international quality criteria UKAS ISO-9001:2008. The main machines are with CE licenses

and operation manual. Any quality problem, which belongs to the manufacture responsibility, will be offered free after-sales service for a year. All the products are standard pass quality. FAQ The purchaser offers the flat drawing of the workroom. The supplier should provide the relative technology for the chocolate equipments; the power source arrangement, the technology and the layout designing service. Packaging & Shipping The chocolate production equipments, aux. packed with PE/PP film in inner. outside by standard export woodcase. In shanghai port loading machine.

Customer visit:

Exhibition:

Exhibition:

Related Keywords

Related Keywords