Plastic PVC pipe fabrication machine with price

- Delivery Time:

- 40 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Jiangsu, China (Mainland) |

|---|

Product Description

Product Description

Product Description Plastic PVC pipe fabrication machine with price

1) The conical double screws are with the newest structure and variable pitch improve the output by over 30%.

2) The hardened gear surface of the gearbox guarantees the heavy duty load and long service life. 3) Twin and multi-track system, and track can be adjusted for different sizes of pipes ranging from 16mm to 630mm 4) Automatic Cutting unit can be used according to your specific requirements. The working process of PVC pipe fabrication machine: Raw material+additive → mixing → feeding → conical double screw extruder → mould → vacuum cooling tank → haul-off unit → automatic cutting machine → stacker. Auxiliary equipments: mixer, printer, crusher, pulverizer, air compressor, water tower or chiller, belling machine, etc.

Packaging & Shipping Main parts of PVC pipe fabrication machine are be covered by film, then be placed on wood pallets, next be fixed in containers. Our Services 1) We recommend of machine and auxiliary equipments and relevant budgeting, human resources allocation and budgeting.

Packaging & Shipping Main parts of PVC pipe fabrication machine are be covered by film, then be placed on wood pallets, next be fixed in containers. Our Services 1) We recommend of machine and auxiliary equipments and relevant budgeting, human resources allocation and budgeting.

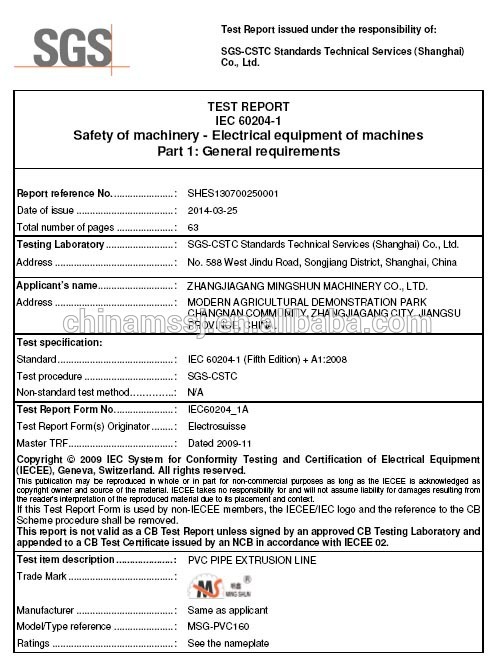

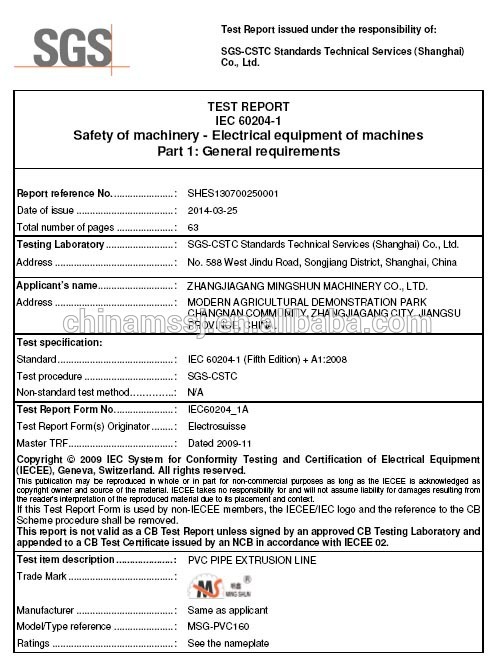

2) We would like to answer any inquiry within 48 hours and it will be solved as soon as possible. 3) The buyer can send the worker to our company for training. 4) The Seller supplies the complete technical support documents and the relative drawings of the electric components written in Chinese and English. 5) Our engineer can be to the Buyer’s company for installation and testing the lines. Company Information 1) Our factory is near Shanghai city. We are a gold supplier of Alibaba for 8 years. We have ISO9001:2008 and SGS.

2) We manufacture plastic straight/coiled pipe machine, pipe belling machine, plastic profile/panel/ceiling machine, plastic pelletizing line, shredder, mixer, crusher and so on.

3) In last few years we have exported to Russia, Belarus, Ukraine, South Africa, Nigeria, Zambia, Morocco, Saudi Arabia, Egypt, Jordan, Lebanon, Pakistan, India, Burma, Bangladesh, Uzbekistan, Argentina, Mexico, Brazil, Uruguay, etc. 4) For some main parts, we usually use Siemens/ABB/Omron/ Schneider brands in order to ensure better quality.

1) The conical double screws are with the newest structure and variable pitch improve the output by over 30%.

2) The hardened gear surface of the gearbox guarantees the heavy duty load and long service life. 3) Twin and multi-track system, and track can be adjusted for different sizes of pipes ranging from 16mm to 630mm 4) Automatic Cutting unit can be used according to your specific requirements. The working process of PVC pipe fabrication machine: Raw material+additive → mixing → feeding → conical double screw extruder → mould → vacuum cooling tank → haul-off unit → automatic cutting machine → stacker. Auxiliary equipments: mixer, printer, crusher, pulverizer, air compressor, water tower or chiller, belling machine, etc.

Packaging & Shipping Main parts of PVC pipe fabrication machine are be covered by film, then be placed on wood pallets, next be fixed in containers. Our Services 1) We recommend of machine and auxiliary equipments and relevant budgeting, human resources allocation and budgeting.

Packaging & Shipping Main parts of PVC pipe fabrication machine are be covered by film, then be placed on wood pallets, next be fixed in containers. Our Services 1) We recommend of machine and auxiliary equipments and relevant budgeting, human resources allocation and budgeting. 2) We would like to answer any inquiry within 48 hours and it will be solved as soon as possible. 3) The buyer can send the worker to our company for training. 4) The Seller supplies the complete technical support documents and the relative drawings of the electric components written in Chinese and English. 5) Our engineer can be to the Buyer’s company for installation and testing the lines. Company Information 1) Our factory is near Shanghai city. We are a gold supplier of Alibaba for 8 years. We have ISO9001:2008 and SGS.

2) We manufacture plastic straight/coiled pipe machine, pipe belling machine, plastic profile/panel/ceiling machine, plastic pelletizing line, shredder, mixer, crusher and so on.

3) In last few years we have exported to Russia, Belarus, Ukraine, South Africa, Nigeria, Zambia, Morocco, Saudi Arabia, Egypt, Jordan, Lebanon, Pakistan, India, Burma, Bangladesh, Uzbekistan, Argentina, Mexico, Brazil, Uruguay, etc. 4) For some main parts, we usually use Siemens/ABB/Omron/ Schneider brands in order to ensure better quality.

Related Keywords

Related Keywords

You May Also Like

You May Also Like