Best PPR glass fiber pipe making extruder plastic machine production line price

- Delivery Time:

- 40 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Jiangsu, China (Mainland) |

|---|

Product Description

Product Description

Best PPR glass fiber pipe making extruder plastic machine production line price Description of PPR pipe making extruder: 1. Equipped ith polyolefin purposed single-screw extruder; it has the characters of quick extruding, high efficiency and so on.

2. The specially designed co-extrusion die head is reasonable in flow channel, smooth in both internal and external walls, and small in internal stress.

3. Pipe diameter is among 20-160mm and production speed reaches to 18m/min.

4.One unit serves several purposes. It can produce common PP-R, Nanometer anti-bacteria pipe, PE-RT and PE-X.

5. If added one co-extrusion engine and die on original base, it can produce PP-R fiberglass reinforced composite pip Process Flow of PPR pipe making extruder: Raw material +master batches → mixing→vacuum feeding → material dryness → single screw extruder → single screw extruder → single screw extruder → color string extruder → spiral co-extrusion mould → calibrator → spray vacuum calibration tank → spray cooling water tank → spray-code printer → belt haul-off → no-dust cutter → pipe rack→finished product inspecting &packing Technical parameters of PPR pipe making extruder:

Pictures of PPR pipe making extruder:

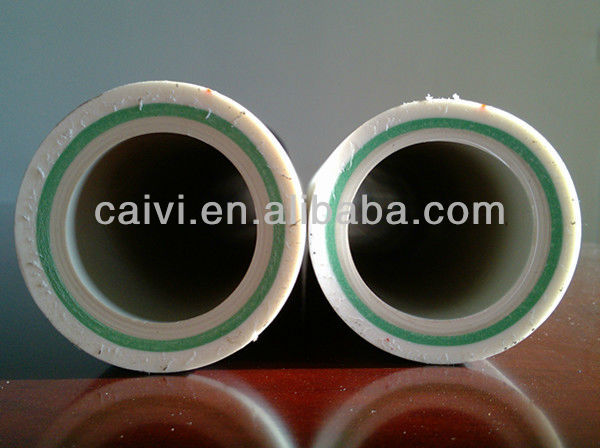

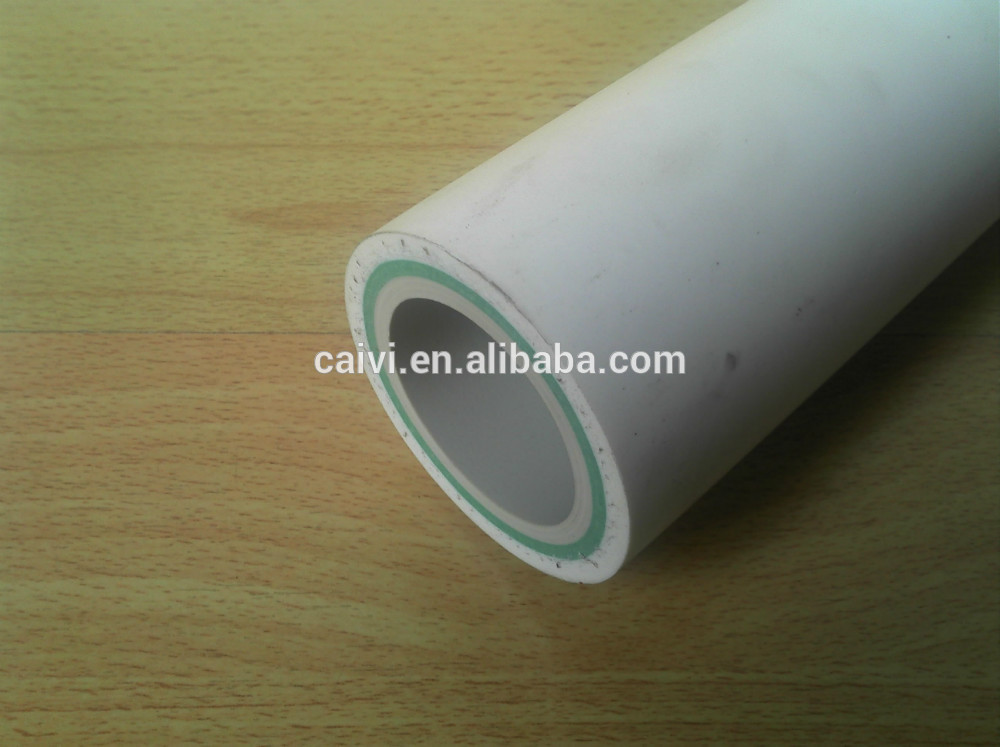

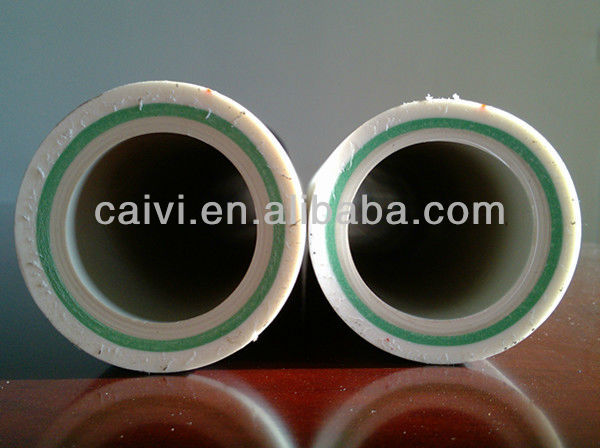

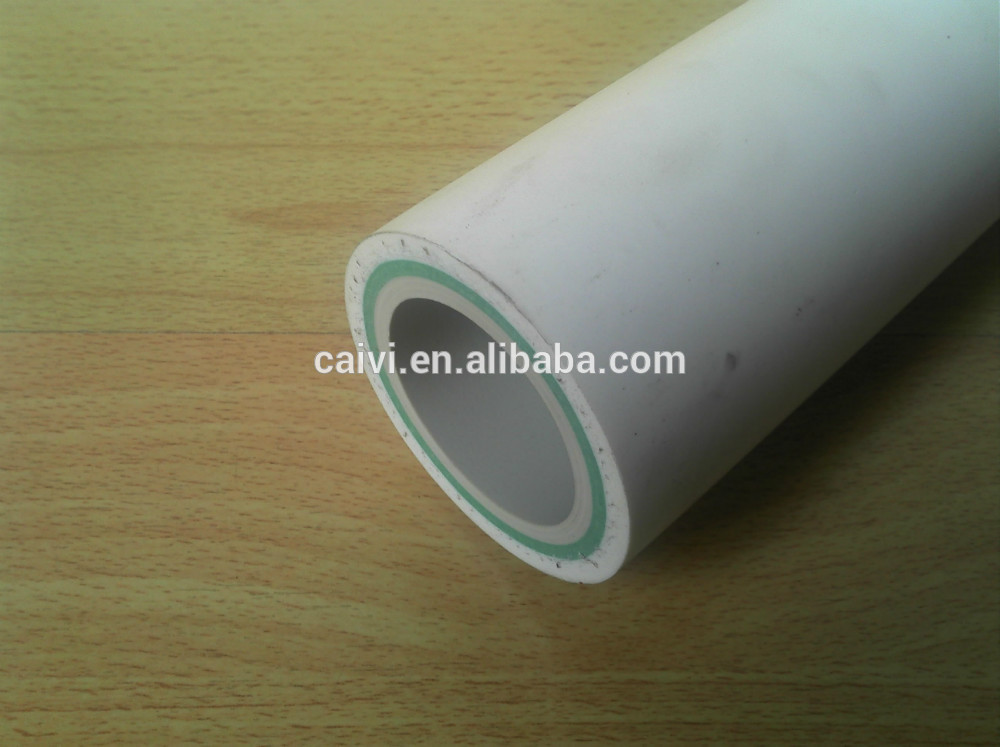

Finished products:

Finished products:

Exhibition Show:

Exhibition Show:  Shipping Show:

Shipping Show:  If you want more information about PPR pipe making extruder, please contact us, thanks! Our company is near Shanghai, about 130km. Welcome to our factory anytime! Skype: caivisales1 Alice Chow

If you want more information about PPR pipe making extruder, please contact us, thanks! Our company is near Shanghai, about 130km. Welcome to our factory anytime! Skype: caivisales1 Alice Chow

2. The specially designed co-extrusion die head is reasonable in flow channel, smooth in both internal and external walls, and small in internal stress.

3. Pipe diameter is among 20-160mm and production speed reaches to 18m/min.

4.One unit serves several purposes. It can produce common PP-R, Nanometer anti-bacteria pipe, PE-RT and PE-X.

5. If added one co-extrusion engine and die on original base, it can produce PP-R fiberglass reinforced composite pip Process Flow of PPR pipe making extruder: Raw material +master batches → mixing→vacuum feeding → material dryness → single screw extruder → single screw extruder → single screw extruder → color string extruder → spiral co-extrusion mould → calibrator → spray vacuum calibration tank → spray cooling water tank → spray-code printer → belt haul-off → no-dust cutter → pipe rack→finished product inspecting &packing Technical parameters of PPR pipe making extruder:

Model | Screw diameter | L/D | Extruder | Pipe range | Capacity (kg/h) | Power(km) | Total power | Line length |

FP-PPR-63A | 50mm | 33:1 | 4 | 20-63 | 100-200 | 22*3 | 120 | 30 |

FR-PPR-63B | 65mm,50mm | 33:1 | 3 | 20-63 | 100-180 | 37*1,22*1 | 110 | 30 |

PR-PPR-110A | 65mm | 33:1 | 4 | 20-110 | 180-300 | 37*3 | 190 | 38 |

FR-PPR-110B | 75mm,65mm | 33:1 | 3 | 20-110 | 150-200 | 55*1,37*1 | 180 | 38 |

Finished products:

Finished products:

Exhibition Show:

Exhibition Show:  Shipping Show:

Shipping Show:  If you want more information about PPR pipe making extruder, please contact us, thanks! Our company is near Shanghai, about 130km. Welcome to our factory anytime! Skype: caivisales1 Alice Chow

If you want more information about PPR pipe making extruder, please contact us, thanks! Our company is near Shanghai, about 130km. Welcome to our factory anytime! Skype: caivisales1 Alice Chow Related Keywords

Related Keywords