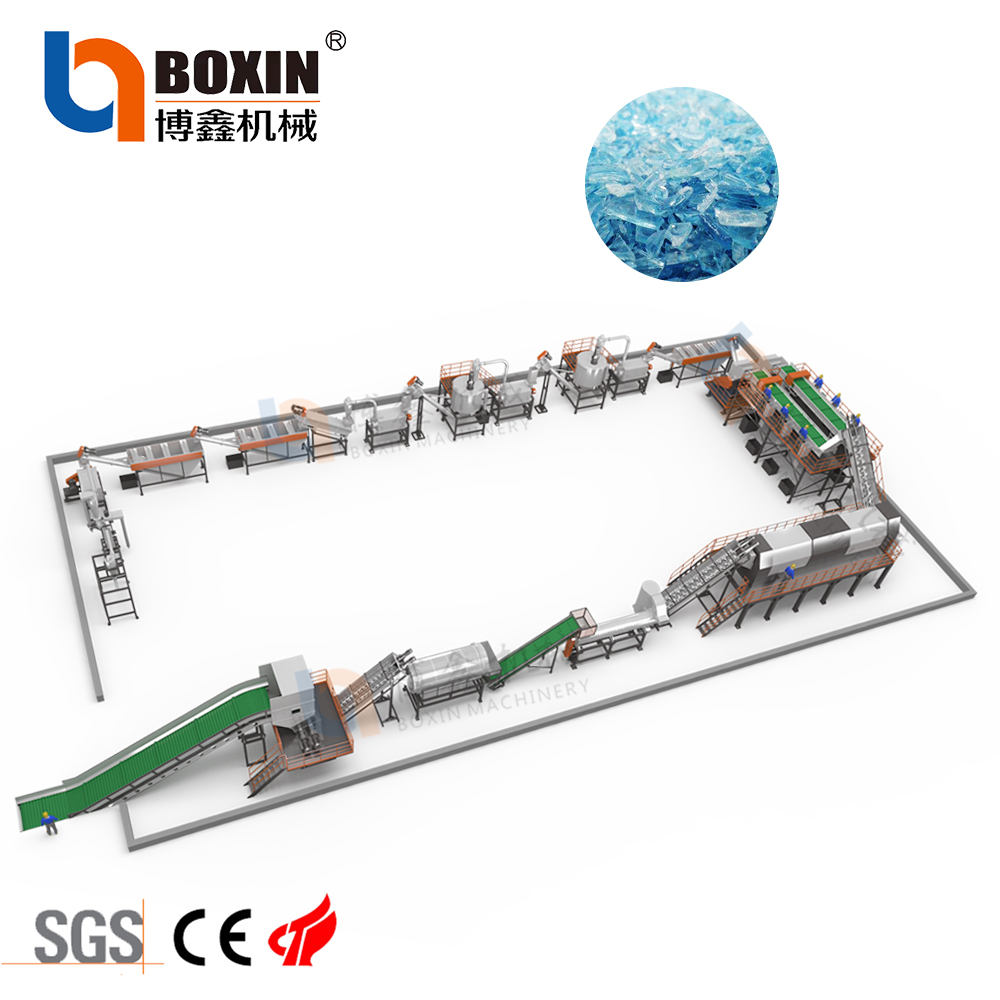

PET Bottle Recycling Machine for Filament Fiber Production (2000KG/H)

$30000.00 - $46000.00/set

- Min. Order:

- 1 set

- Min. Order:

- 1 set

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

Product Description

Product Description

Hot selling machine series

Description

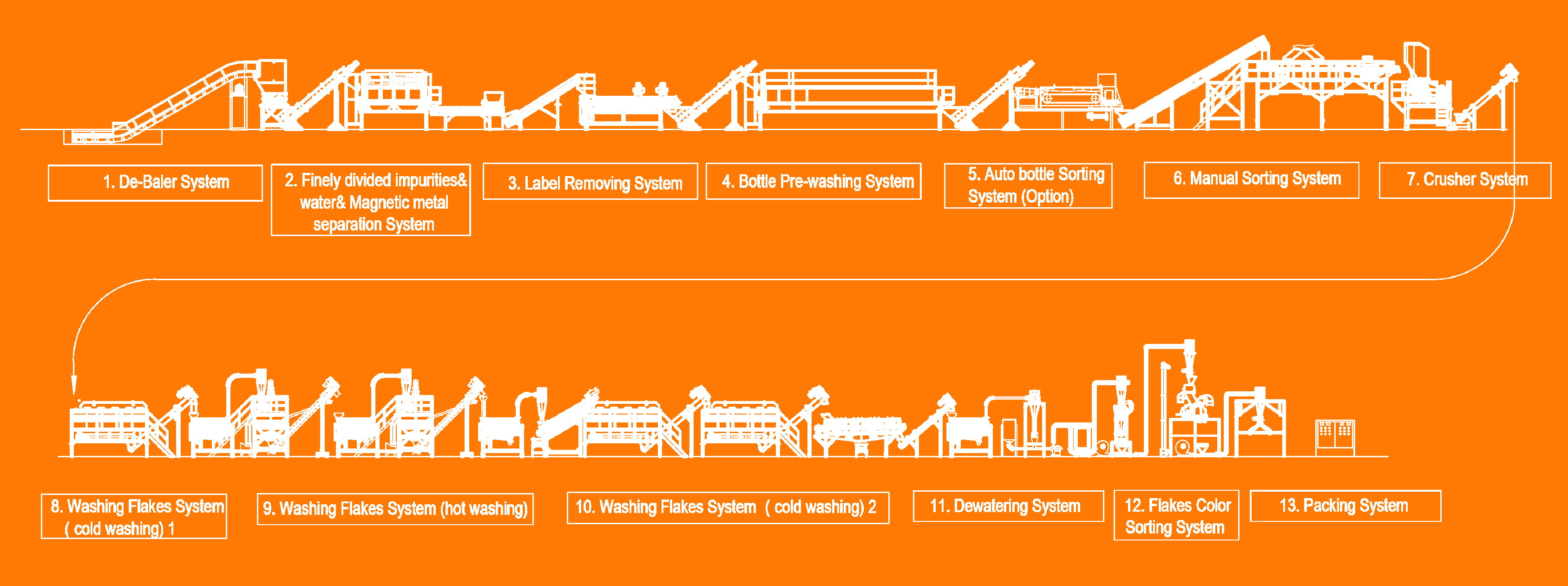

1. This mineral water bottle recycling mainly used for dealing with waste PET bottle, barrel etc.

2. To separate PET bottles to flakes from label, cap, oil, garbage.

3. This PET bottle washing machine is composed of separator, crusher, cold & hot washing system, dewatering, drying, packing

system, etc.

4. Easy to operate,Full automatic.

Conveying PET bottle→lable remover→ manual sorting table → wet crusher→screw loader →Hot washer→screw loader→high speed friction

washer→screw loader→floating washer→screw loader→spray washer → dewater machine → pipe line dryer → label seperator → blower →

hopper

2. To separate PET bottles to flakes from label, cap, oil, garbage.

3. This PET bottle washing machine is composed of separator, crusher, cold & hot washing system, dewatering, drying, packing

system, etc.

4. Easy to operate,Full automatic.

Conveying PET bottle→lable remover→ manual sorting table → wet crusher→screw loader →Hot washer→screw loader→high speed friction

washer→screw loader→floating washer→screw loader→spray washer → dewater machine → pipe line dryer → label seperator → blower →

hopper

Product Paramenters

Device parameters | ||||||||

Model | BXA-500 | BXA-1000 | BXA-2000 | BXA-3000 | ||||

Output(KG/H) | 500KG/H | 1000KG/H | 2000KG/H | 3000KG/H | ||||

Installation power | 156KW | 307KW | 420KW | 652KW | ||||

Water consumption | 2Ton/H | 3.5Ton/H | 5Ton/H | 18Ton fist time then 2-3Ton/H | ||||

Product details

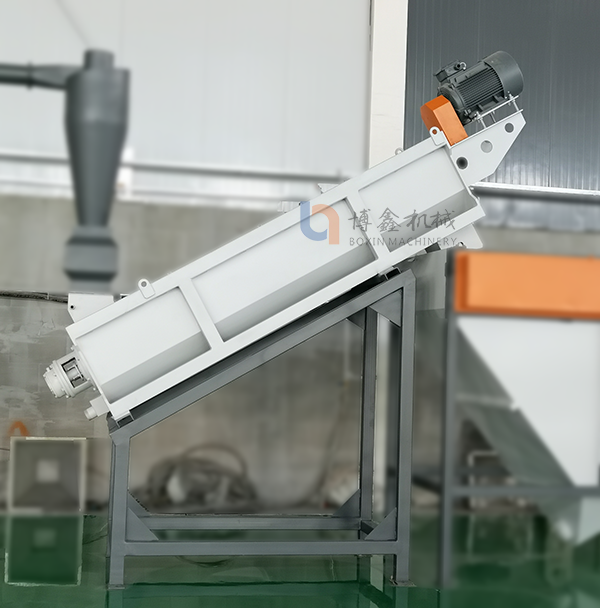

Conveying unpacking system

The metal chain plate conveyor with adjustable speed greatly improves the efficiency

The unpacking machine adopts the special structural design of angle 2-axis unpacking and 2-axis breaking, which is fully dissolved

Bottle bricks ensure the subsequent conveying process and minimize energy consumption.

The unpacking machine adopts the special structural design of angle 2-axis unpacking and 2-axis breaking, which is fully dissolved

Bottle bricks ensure the subsequent conveying process and minimize energy consumption.

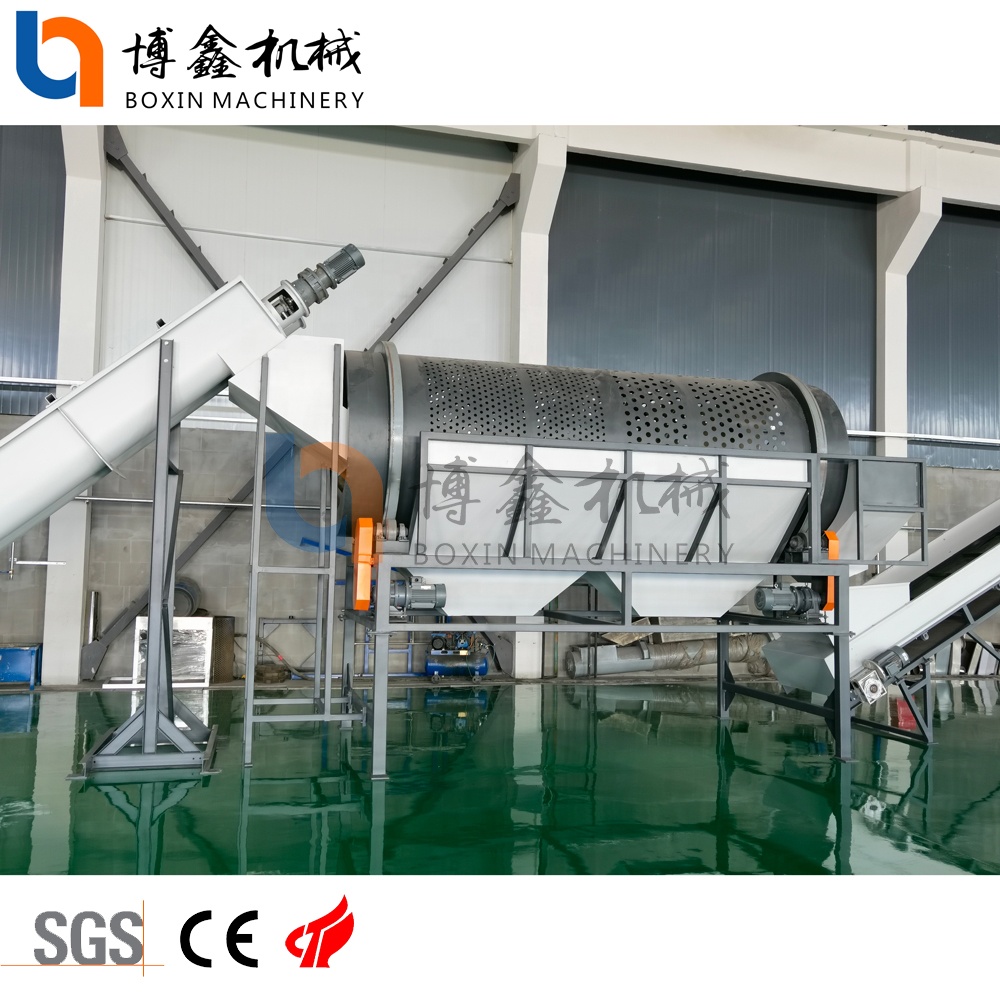

Trommel machine

Adopt high performance tommel machine to separate the external sand,metal,stone,glass from raw material,in order to reduce the production prestreet,reduce equiment wear and capacity consumption and effectively improve product quality.

Remover label system

It is mainly used to peel off the label paper on the surface of pet;

Ensure the integrity of bottles and bottlenecks and reduce the loss of high-quality bottle mouth materials.

Ensure the integrity of bottles and bottlenecks and reduce the loss of high-quality bottle mouth materials.

Sorting system

Final classification and screening of bottle body before crushing;

The separation system is a necessary way to ensure the quality of the product by screening out the foreign matters left in each

unit in the front section.

The separation system is a necessary way to ensure the quality of the product by screening out the foreign matters left in each

unit in the front section.

Crushing system

Different models of crushers are selected according to different output;

The main shaft and box of the crusher are made of

wear-resistant materials, which is safer and more durable.

wear-resistant materials, which is safer and more durable.

High speed friction cleaning system

Add high-speed friction cleaning machine to remove impurities more effectively and achieve ideal cleaning effect.

Floating washer machine

Through the physical principle, using the specific gravity difference between different plastics, using water as the medium, PP or HDPE is separated, so that the PET bottle slices can achieve the effect of purification

Hot washing system

Thermal cleaning can effectively remove the residual glue, oil stain and some small impurities on the surface of the bottle, which

is very important to the service life and product quality of the filter components of the downstream products.

is very important to the service life and product quality of the filter components of the downstream products.

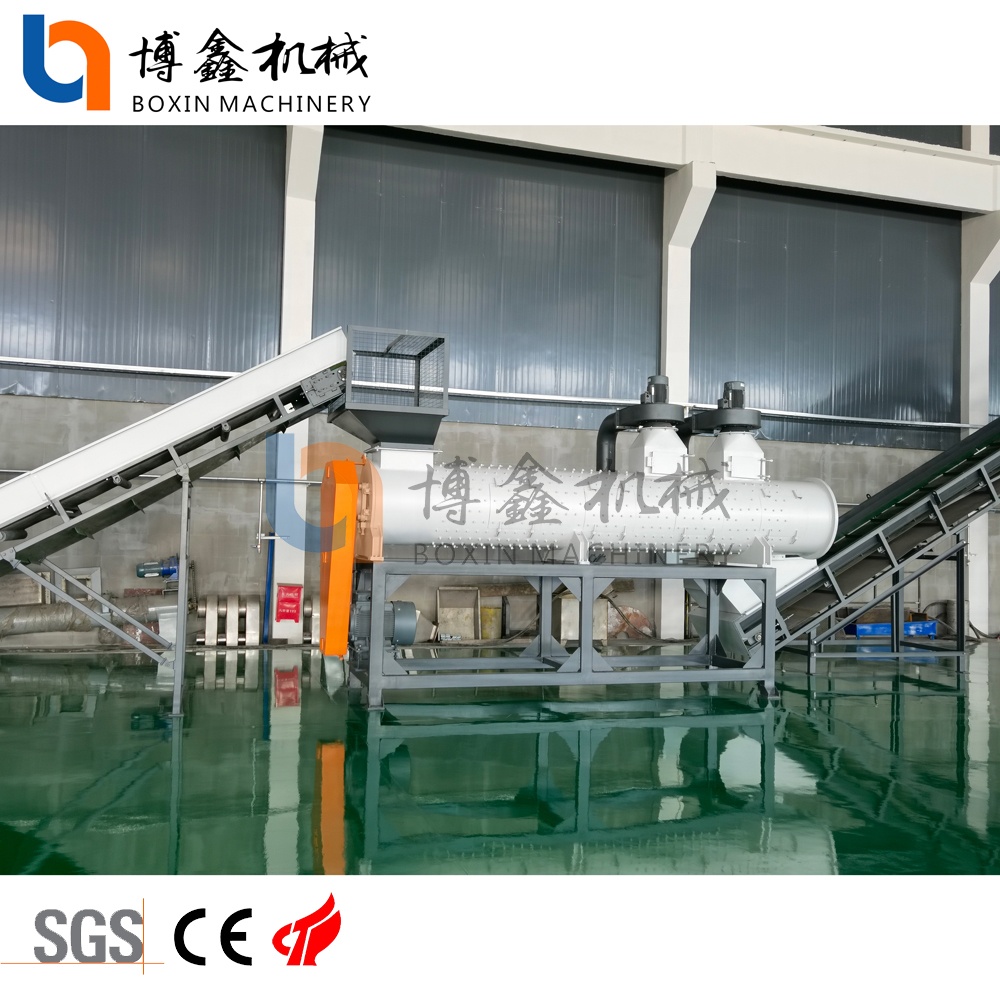

De-watering system

The moisture content of the final material plays a vital role in the next process; The corresponding centrifugal dehydration and

hot air drying system can be equipped according to the moisture content set according to the production requirements.

hot air drying system can be equipped according to the moisture content set according to the production requirements.

Label blower&storage hopper

Label blower Can effectively separate the dust in the bottle sheet, fine plastic label.

BOXIN Machinery plastic recycling technology mainly applied in the field of waste plastic regrinding, washing and regranuling.

Thanks to the R&D ability and well-understanding industries experience, BOXIN Machinery can provide the customized plastics recycling solutions to customers.

Typical productions Machinery can provide are: plastic washing line for PET bottles, PP PE film bags, HDPE Bottles , Plastic

pelletizing recycling line for clean PP PE material , plastic shredder and crushers etc.

Thanks to the R&D ability and well-understanding industries experience, BOXIN Machinery can provide the customized plastics recycling solutions to customers.

Typical productions Machinery can provide are: plastic washing line for PET bottles, PP PE film bags, HDPE Bottles , Plastic

pelletizing recycling line for clean PP PE material , plastic shredder and crushers etc.

HOW TO FIND BOXIN MACHINE?

● Search Alibaba, Made in China, Google, Youtube and Facebook.

● Visit exhibition in differentcountries

● Send BOXIN Machine an request and tell your basic inquiry

● BOXIN Machine sales manager will reply you in short timeand add instant chatting tool

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME.

● If we can fullfill your request and you interested in

our products, you may pay a visit to BOXIN Machine site

our products, you may pay a visit to BOXIN Machine site

● The meaning of visiting supplier, because seeing is believing, BOXINMachine with own manufacture and developed& research team, we can send you engineers and make sure your after sales service.

HOW TO GUARANTEE YOUR FUNDS TO BE SAFE AND DELIVERY TO BE ON TIME?

● Through Alibaba letter guarantee service, it will ensure the ontime delivery and the quality of the equipment you want to buy.

● By letter of credit, you can lock the delivery time easily.

●After the factory visit, You can ensure the facticity of our bank account.

SEE BOXIN MACHINE HOW TO ENSURE THE QUALITY!

● In orderto ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulatedprofessional processing methods over the past years.

● Each component before assembly needs strictly control by inspectingpersonnel.

● Each assembly is in charged by a master who has working experience for more than 20 years

●After all the equipmentare completed, we will connect all the machines and run the full production line to ensure the stable running in customers'factory

THE AFTER-SALE SERVICE OF BOXIN MACHINE!

● After finish the production, we will debug the production line, take photos,videos and send them to customers e-mail or instant tools.

● After the commissioning, we will package the equipment by standard

export package for shipment.

export package for shipment.

● According to the customer's request, we can arrange our engineers to customers' factory to do the

installation and training.

installation and training.

● Engineers, sales managers and after-sales service manager will form a after-sales team, online andoff line, to follow the customers' project.

if you want to know more details about BOXIN machine ,welcome to send us an inqury now!

Related Keywords

Related Keywords

You May Also Like

You May Also Like