Hot Wash PET Bottle to Fiber Recycling Machine Line

$30000.00 - $46000.00/set

- Min. Order:

- 1 set

- Min. Order:

- 1 set

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

Product Description

Product Description

Products Description

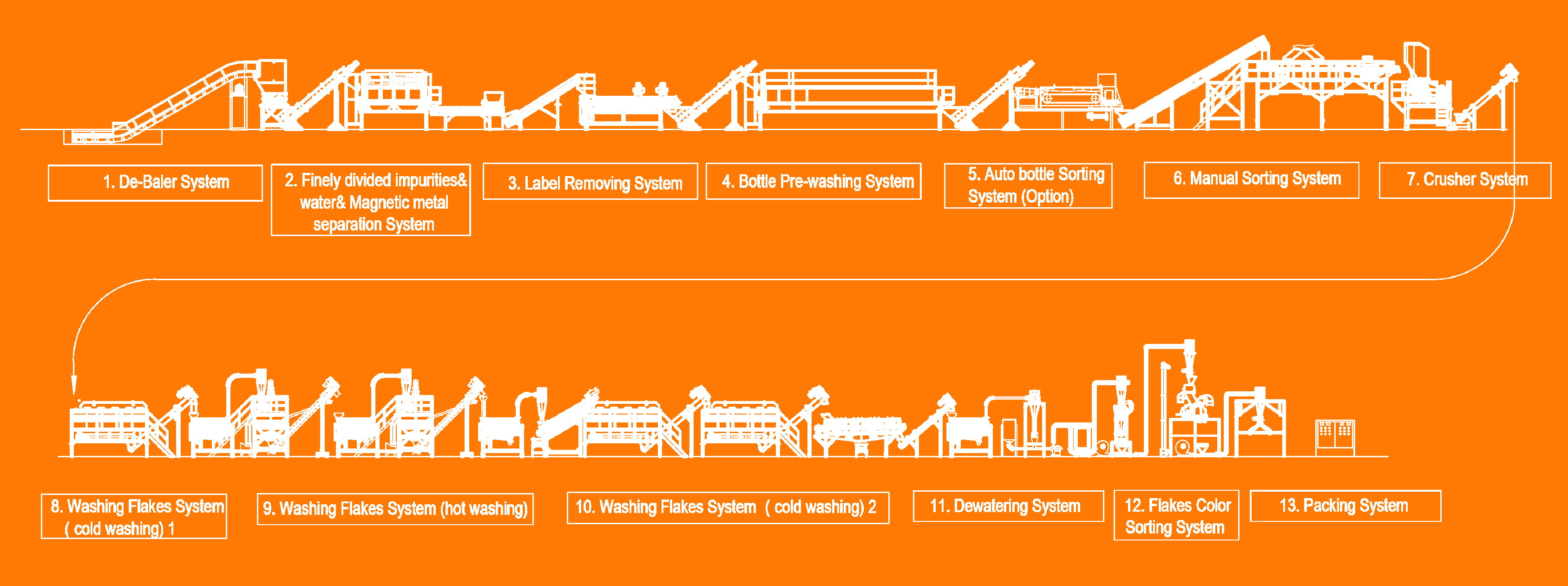

PET bottle washing crushing hot washing waste bottles bales SUS304 recycling machine mainly used to recycling waste PET bottle, PP PE HDPE hard bottles flakes, Blue Drums Chemical barrel, PVC and some other plastics. The whole line is fully automatic and it has characteristics of high efficiency, low noise and easy operation.the humidity of final output could be within 1%.It adopts hot water washing to get good quality. Various output capacities can be chosen: 500kg/h, 1000kg/h, 1500kg/h 2000kg/h.3000kg/h,5000kh/h.

The waste dirty material go through delabelling, crushing, washing, drying, and collecting process will turn to be clean flakes for reuse.

This pet bottle washing machine can be displayed "L" or "U" shape according to clients' workshop.

We can also customize the washing line components according to client's material and product requirement.

We can also customize the washing line components according to client's material and product requirement.

Technical Parameter

Model | Output (KG/H) | Installed Power (KW) | Water Consumption (T/H) | Labor Requirements | Factory Area(L*W*H) |

BXA -500 | 500 | 160-180 | 2-3 | 2-3 | 70*5*5 |

BXA -1000 | 1000 | 210--260 | 3-5 | 4-5 | 85*5*5 |

BXA -2000 | 2000 | 400-460 | 6-8 | 5-6 | 100*8*6 |

BXA -3000 | 3000 | 600-670 | 10-12 | 6-8 | 120*6*6 |

BXA -5000 | 5000 | 920-1200 | 12-15 | 8-10 | 135*8*7 |

Welcome to BOXIN

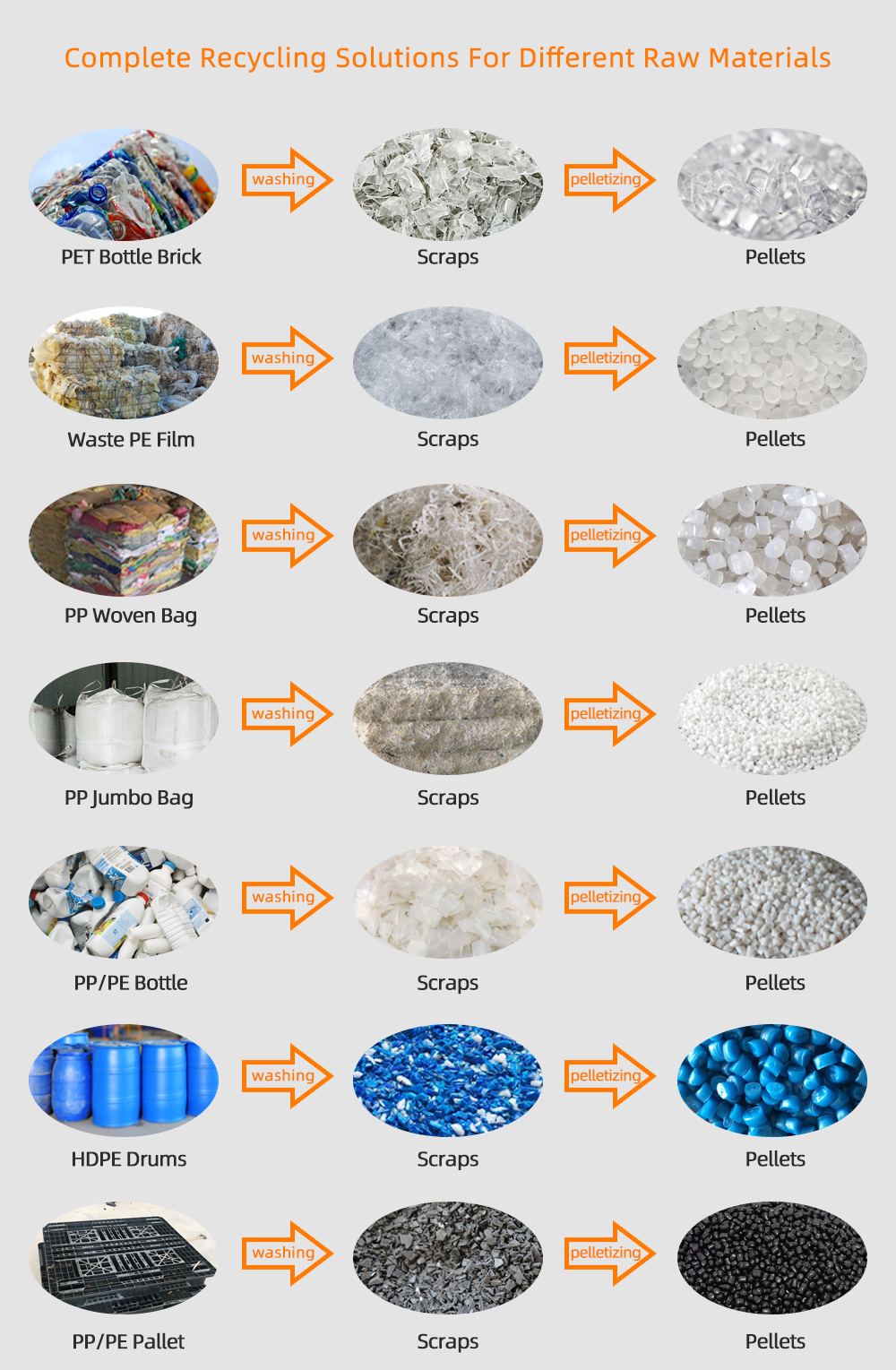

BOXIN Machinery plastic recycling technology mainly applied in the field of waste plastic regrinding, washing and regranuling.

Thanks to the R&D ability and well-understanding industries experience, BOXIN Machinery can provide the customized plastics recycling solutions to customers.

Typical productions Machinery can provide are: plastic washing line for PET bottles, PP PE film bags, HDPE Bottles , Plastic pelletizing recycling line for clean PP PE material , plastic shredder and crushers etc.BOXIN Machinery plastic recycling technology mainly applied in the field of waste plastic regrinding, washing and regranuling.

Thanks to the R&D ability and well-understanding industries experience, BOXIN Machinery can provide the customized plastics recycling solutions to customers.

Typical productions Machinery can provide are: plastic washing line for PET bottles, PP PE film bags, HDPE Bottles , Plastic pelletizing recycling line for clean PP PE material , plastic shredder and crushers etc.

Thanks to the R&D ability and well-understanding industries experience, BOXIN Machinery can provide the customized plastics recycling solutions to customers.

Typical productions Machinery can provide are: plastic washing line for PET bottles, PP PE film bags, HDPE Bottles , Plastic pelletizing recycling line for clean PP PE material , plastic shredder and crushers etc.BOXIN Machinery plastic recycling technology mainly applied in the field of waste plastic regrinding, washing and regranuling.

Thanks to the R&D ability and well-understanding industries experience, BOXIN Machinery can provide the customized plastics recycling solutions to customers.

Typical productions Machinery can provide are: plastic washing line for PET bottles, PP PE film bags, HDPE Bottles , Plastic pelletizing recycling line for clean PP PE material , plastic shredder and crushers etc.

Products Display

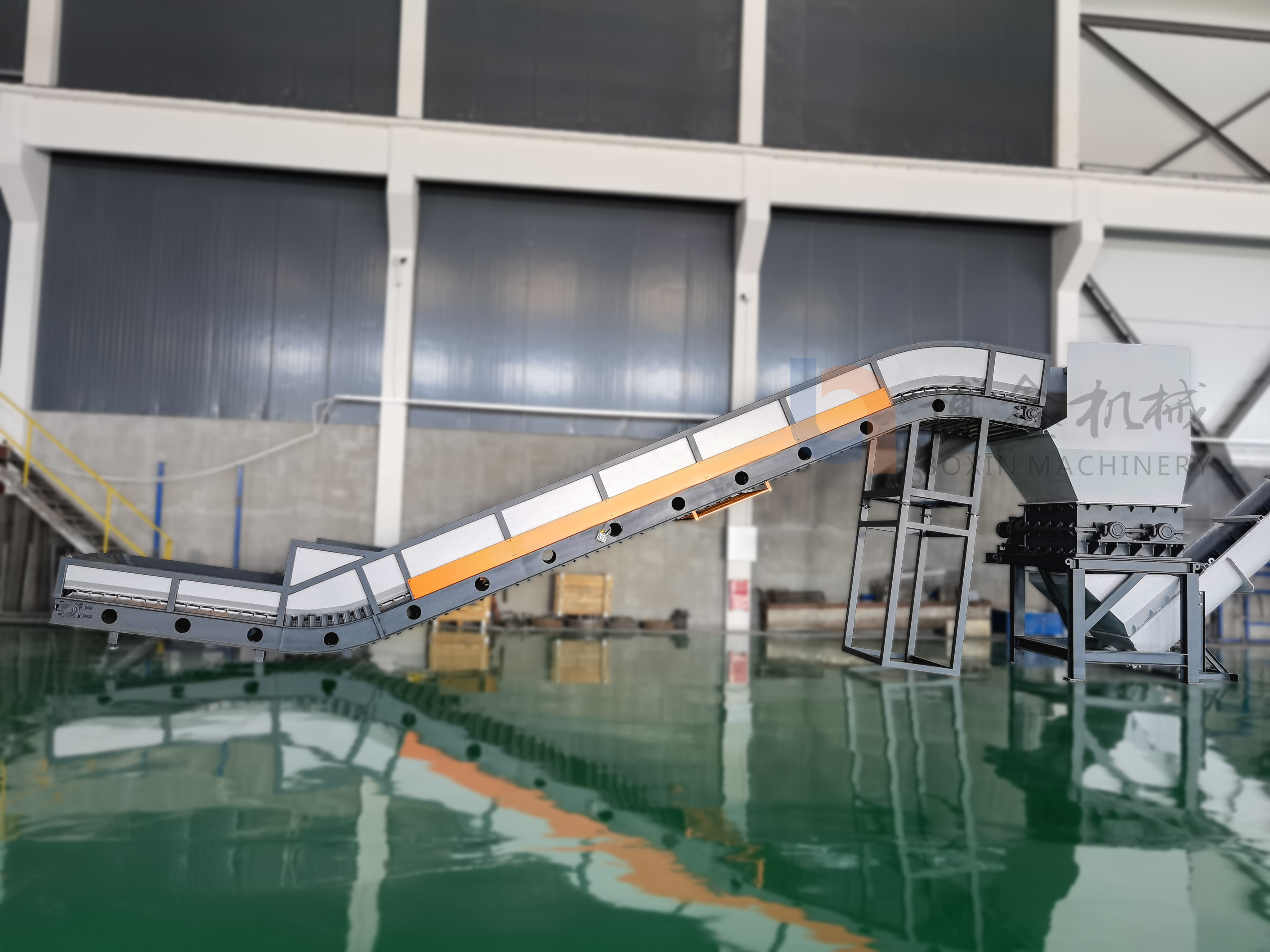

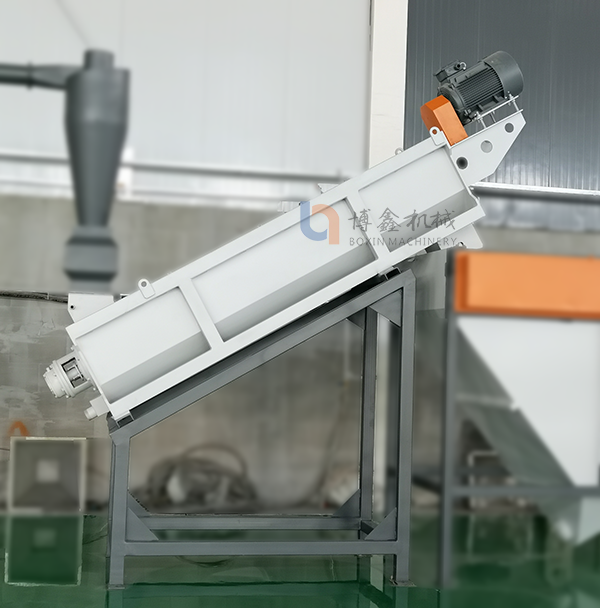

01 Conveying unpacking system

The unpacking machine adopts the special structural design of angle 2-axis unpacking and 2-axis breaking, which is fully dissolved Bottle bricks ensure the subsequent conveying process and minimize energy consumption.The metal chain plate conveyor with adjustable speed greatly improves the efficiency and is more durable.

The unpacking machine adopts the special structural design of angle 2-axis unpacking and 2-axis breaking, which is fully dissolved Bottle bricks ensure the subsequent conveying process and minimize energy consumption.

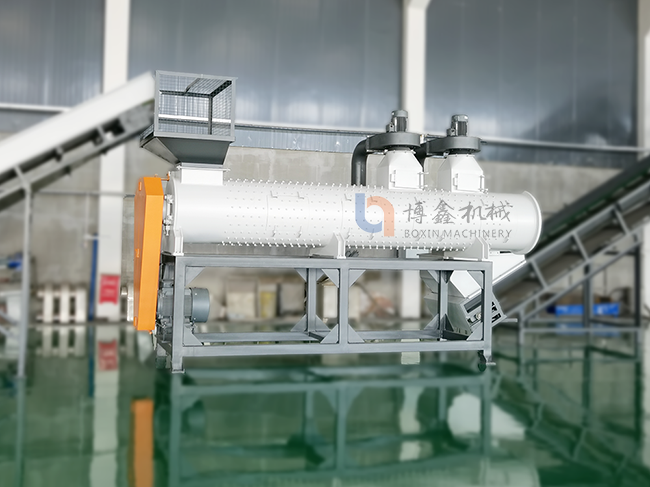

02 Remover label system

Ensure the integrity of bottles and bottlenecks and reduce the loss of high-quality bottle mouth materials.

03 Sorting system

The separation system is a necessary way to ensure the quality of the product by screening out the foreign matters left in each unit in the front section.

04 Crushing system

The main shaft and box of the crusher are made of wear-resistant materials, which is safer and more durable.

05 High speed friction cleaning system

06 Hot washing system

07 De-watering system

The corresponding centrifugal dehydration and hot air drying system can be equipped according to the moisture content set according to the production requirements.

Recommend Products

Contact Us

Related Keywords

Related Keywords

You May Also Like

You May Also Like