Waste Plastic HDPE Washing Line 500-5000kg/h: Bucket & Barrel Cleaning Machine

-

$50000.001-1 unit

-

$46000.00≥2 unit

- Min. Order:

- 1 unit

- Min. Order:

- 1 unit

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

Product Description

Product Description

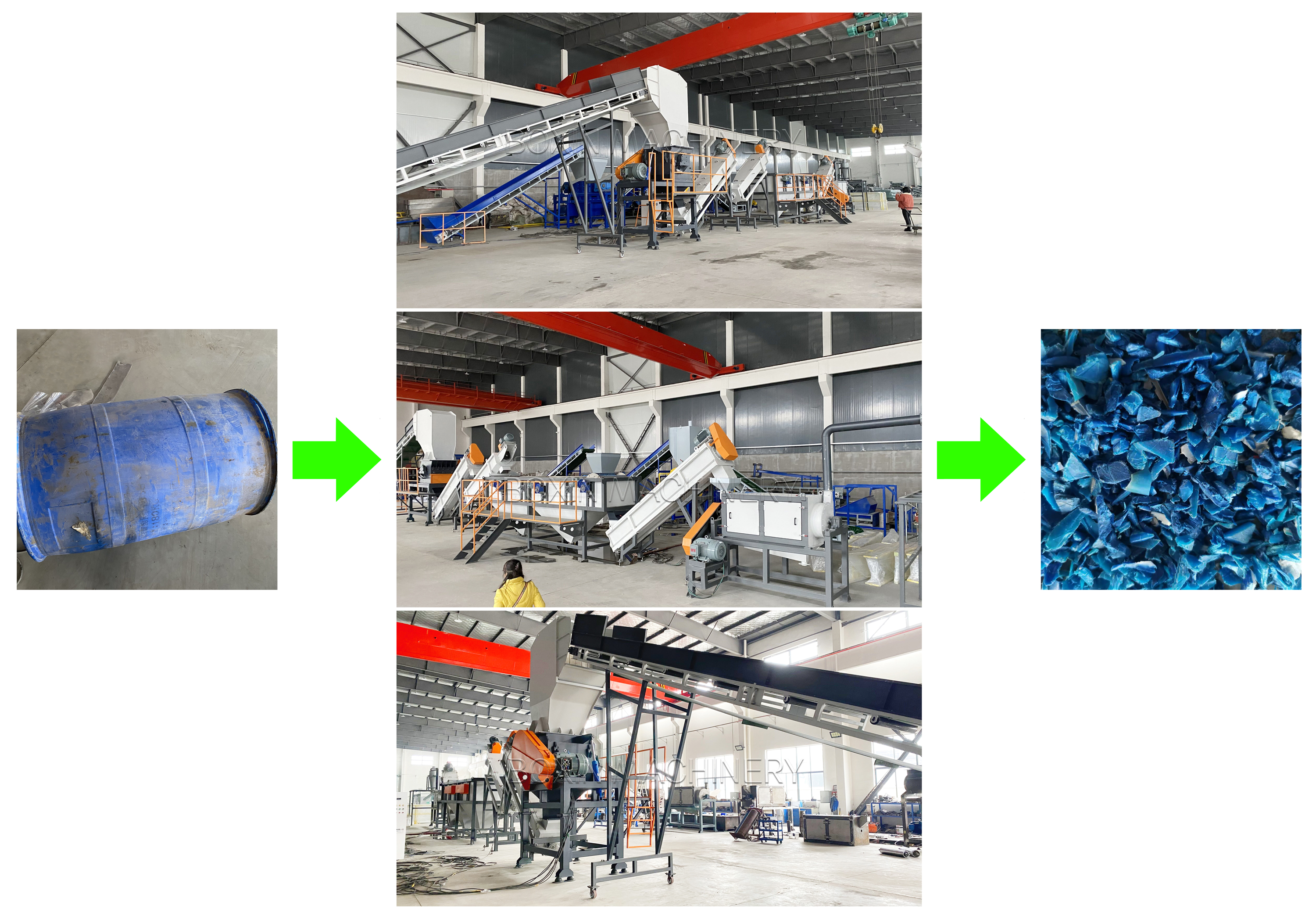

500-5000kg/h Waste Plastic HDPE Bucket Blue Barrel Washing Machine Plastic Washing Line

Products Description

Product description

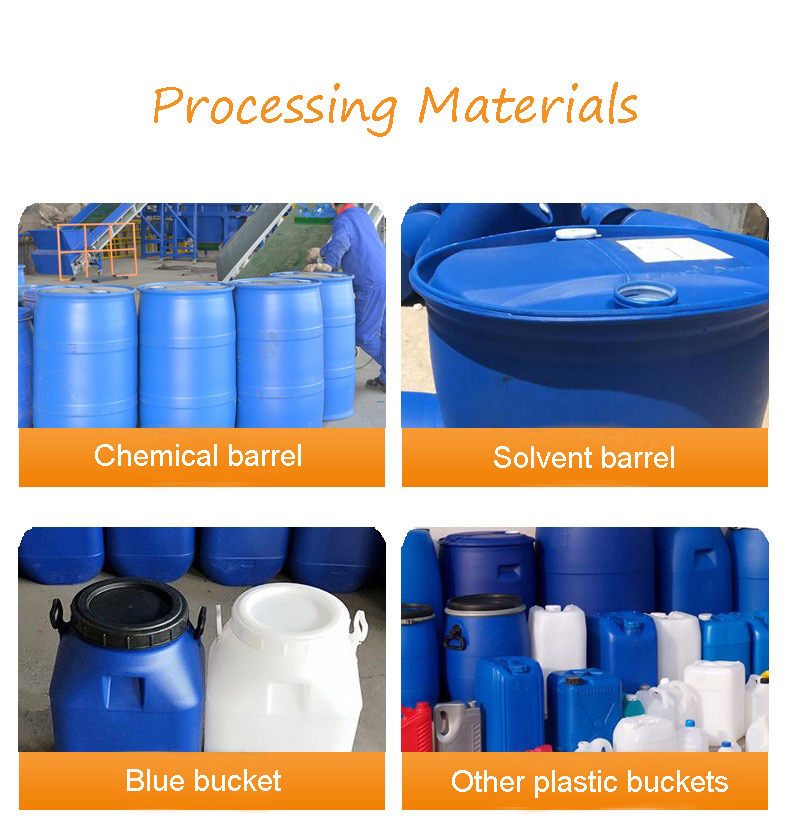

1. This plastic recycling machine mainly used for dealing with waste PP PE HDPE bucket/bottle, etc.

2. To separate PP PE buckets/bottles to flakes from label, cap, oil, garbage.

3. This HDPE Basket Recycling Washing Line is composed of crusher, cold washing system, dewatering, drying, packing system, etc.

4. Easy to operate,Full automatic.

Working flow

Conveying PP PE bottle → crusher→screw loader →friction washer→high speed friction washer→screw loader→floating washer→screw loader→ dewater machine → pipe line dryer → blower →hopper

Project evaluation

Raw material: waste plastic PP PE bottle

Finished product: Clean PP PE flakes:

1. water content: ≤1%

2. stacking density: 0.25-0.35 g/m³

3. flakes size: 6-14mm (the size can be design according to customer request)

8-12mm ≥ 90%

≥12mm: ≤ 2%

fine granule: ≤ 3%;

powder: ≤ 5%

4.Power supply: 330V,3phases,60HZ

5.Total electrical needed: about 194kw (actual consumption:(70%-80%)

6.Size:106м*6м*5.8м, the height of factory must be over 6M, production line can be placed in a line or an angle (Need to provide plant lay out drawing.)

7.Water needed: about4-6t/h. Equip with water treatment if needed.

1. This plastic recycling machine mainly used for dealing with waste PP PE HDPE bucket/bottle, etc.

2. To separate PP PE buckets/bottles to flakes from label, cap, oil, garbage.

3. This HDPE Basket Recycling Washing Line is composed of crusher, cold washing system, dewatering, drying, packing system, etc.

4. Easy to operate,Full automatic.

Working flow

Conveying PP PE bottle → crusher→screw loader →friction washer→high speed friction washer→screw loader→floating washer→screw loader→ dewater machine → pipe line dryer → blower →hopper

Project evaluation

Raw material: waste plastic PP PE bottle

Finished product: Clean PP PE flakes:

1. water content: ≤1%

2. stacking density: 0.25-0.35 g/m³

3. flakes size: 6-14mm (the size can be design according to customer request)

8-12mm ≥ 90%

≥12mm: ≤ 2%

fine granule: ≤ 3%;

powder: ≤ 5%

4.Power supply: 330V,3phases,60HZ

5.Total electrical needed: about 194kw (actual consumption:(70%-80%)

6.Size:106м*6м*5.8м, the height of factory must be over 6M, production line can be placed in a line or an angle (Need to provide plant lay out drawing.)

7.Water needed: about4-6t/h. Equip with water treatment if needed.

Machine list | ||||||

1.0 | Belt conveyor | 6.0 | Friction washer | |||

2.0 | Crusher(include platform) | 7.0 | De-watering machine | |||

3.0 | Friction washer | 8.0 | Zig-zag label blower | |||

4.0 | High speed friction washer | 9.0 | Silo | |||

5.0 | Float washing tank | 10.0 | Electric cabinet | |||

Technical Characteristics

Input capacity | 500kg/h | 1000 kg/h | 2000 kg/h | 3000kg/h |

Workshop(M*M*M) | 30 (L)×10(W)×5(H) | 50(L)×12(W)×6(H) | 70(L)×12(W)×6(H) | 100(L)×15(W)×6(H) |

Ancillary staff | 6 | 8 | 12 | |

Installation power | 175KW | 198KW | 306KW | 463KW |

Water consumption | 0-3Ton/h | 0-5Ton/h | 0-10Ton/h | 0-15Ton/h |

Final product | Moisture: max 1% Bulk density: 0.3G/CM3 Particle size: 14-18mm Metal content: max.20ppm Floatable contamination: less than 200ppm Total impurity: 320ppm | Moisture: max 1% Bulk density: 0.3G/CM3 Particle size: 14-18mm Metal content: max. 20oom Floatable contamination: less than 200ppm Total impurity: 320ppm | Moisture: max 1% Bulk density: 0.3G/CM3 Particle size: 14-18mm Metal content: Max. 20ppm Floatable contamination: less than 200ppm Total impurity: 320ppm | Moisture: max 1% Bulk density: 0.3G/CM3 Particle size: 14-18mm Metal content: Max. 20ppm Floatable contamination: less than 200ppm Total impurity: 320ppm |

Belt conveyor

Usage: conveying materials

Belt material: PVC

Height adjustable Easy to move with wheels There are anti-skid devices on the surface of the conveyor belt.

Crusher

Usage: used for crushing materials

Opening method of upper hopper: hydraulic

Broken with water

Friction washer

Usage: by injecting high-pressure water, effectively remove debris on the surface of the material.

Body material: stainless steel

High speed friction washer

Purpose: by injecting high pressure water, it can effectively remove impurities.

Body material: stainless steel

Float washing tank

Usage: separation of impurities by precipitation

Body material: stainless steel

Friction washer

Usage: by injecting high-pressure water, effectively remove debris on the surface of the material.

Body material: stainless steel

De-watering machine

Usage: remove moisture

Body material: stainless steel

Silo

Usage: Temporary storage of materials

Body material: stainless steel

Recommend Products

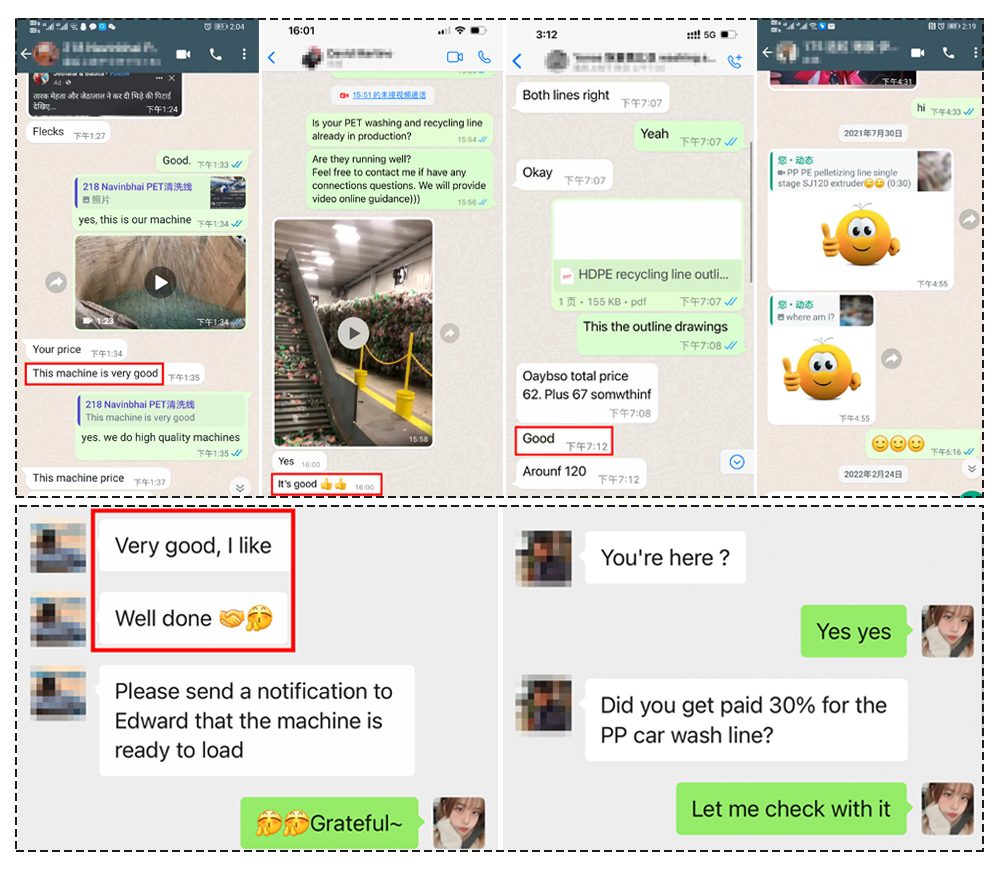

Service&Customer

Packaging&Delivery

1) Are we manufacture or trade company?

We are manufacture,have 15 years' experiences in this field.

2) What kind machines we produce?

Our factory produce plastic washing and recycling machines, plastic granulation machines.

3) What kind payment we accept?

Payment term like T/T, L/C.

4) How long we need to produce the machines?

According to different machine model and configuation, we need different time, like 40 days to 2 months.

5) Will the machine be delivered on time ?

Sure,we will deliver your machine up recieving the balance payment.

6) How about the machine quality?

Our machine quality is reliable.We select every parts on the machine strictly and production and installation is done by

professional workers.We test the each production step for the best machine.

7) How about the price?

You know ,the goods counts the the price.We select the best machine raw material such as siemens electrics,schneider and ABB etc.We will provide you the best machine with best price.

8) How long is your machine’s guarantee time?

One year

9) What can you provide for after sale service?

We can send engineers to your factory for installation and training.also 24 hours on-line service for you.

We are manufacture,have 15 years' experiences in this field.

2) What kind machines we produce?

Our factory produce plastic washing and recycling machines, plastic granulation machines.

3) What kind payment we accept?

Payment term like T/T, L/C.

4) How long we need to produce the machines?

According to different machine model and configuation, we need different time, like 40 days to 2 months.

5) Will the machine be delivered on time ?

Sure,we will deliver your machine up recieving the balance payment.

6) How about the machine quality?

Our machine quality is reliable.We select every parts on the machine strictly and production and installation is done by

professional workers.We test the each production step for the best machine.

7) How about the price?

You know ,the goods counts the the price.We select the best machine raw material such as siemens electrics,schneider and ABB etc.We will provide you the best machine with best price.

8) How long is your machine’s guarantee time?

One year

9) What can you provide for after sale service?

We can send engineers to your factory for installation and training.also 24 hours on-line service for you.

Related Keywords

Related Keywords

You May Also Like

You May Also Like