HDPE Bucket Waste Plastic PP Bottle Recycling Line

-

$50000.001-2 unit

-

$30000.00≥3 unit

- Min. Order:

- 1 unit

- Min. Order:

- 1 unit

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

Product Description

Product Description

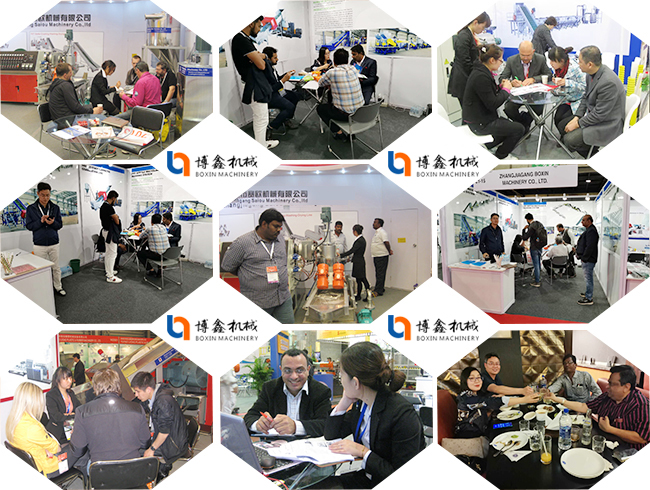

Welcome to BOXIN

Zhangjiagang Boxin Machinery Co., Ltd. is a professional manufacturer of plastic recycling machinery .

With over 20 years of experience, we specialize in producing high-quality plastic washing lines, granulators, crushers, and other recycling equipment for various plastics like PET, PP, PE, HDPE, and LDPE.

Our products help customers improve the efficiency and sustainability of their plastic recycling processes. We are committed to providing innovative solutions and excellent after-sales service.

Products Description

Our PP/PE/HDPE/LDPE Hard Plastic Washing Line is designed for washing and recycling rigid plastic materials, such as bottles, containers, and other waste plastic products.

This high-efficiency washing line effectively removes contaminants like dirt, oil, glue, and labels, making the plastic ready for further processing or reuse.

We provide customized services and tailor a unique solution configuration according to the different needs of each customer.

Technical Characteristics

Belt conveyor

Through the belt conveyor, the materials enter the production line

There are wheels at the bottom, which can be moved and adjusted

Double-layer PVC structure, anti-slip surface treatment, to ensure smooth entry of raw materials.

Crusher

The raw materials enter the crusher through the belt conveyor Our crusher is suitable for processing materials of various

hardness and sizes. The internal screen can be customized according to customer needs to obtain the desired fragment size.

hardness and sizes. The internal screen can be customized according to customer needs to obtain the desired fragment size.

Friction washer

The high-speed rotating blades inside generate a strong impact force, which can effectively remove dirt, grease and other impurities attached to the plastic surface and has a good cleaning effect.

Separation tank

Separates suspended matter and solid particles in water by gravity. Uses density differences between different substances to separate required raw materials from unwanted impurities.

Using material principles will not change the properties of the raw materials and is very efficient.

De-watering machine

The centrifugal dehydrator generates huge centrifugal force through high-speed rotation, which can separate the moisture or liquid in the material in a short time, so it can significantly improve production efficiency.

Silo

Used for raw material storage at the end of the production line

Can be customized according to needs to add more automated equipment.

Model | BXC-500 | BXC-1000 | BXC-2000 | BXC-3000 |

Input capacity | 500kg/h | 1000 kg/h | 2000 kg/h | 3000kg/h |

Installed power (KW) | 80-100 | 120-180 | 180-260 | 260-330 |

Water consumption (T/H) | 3-4 | 3-4 | 4-5 | 6-8 |

Labor requirements | 2-3 | 2-3 | 3-5 | 4-6 |

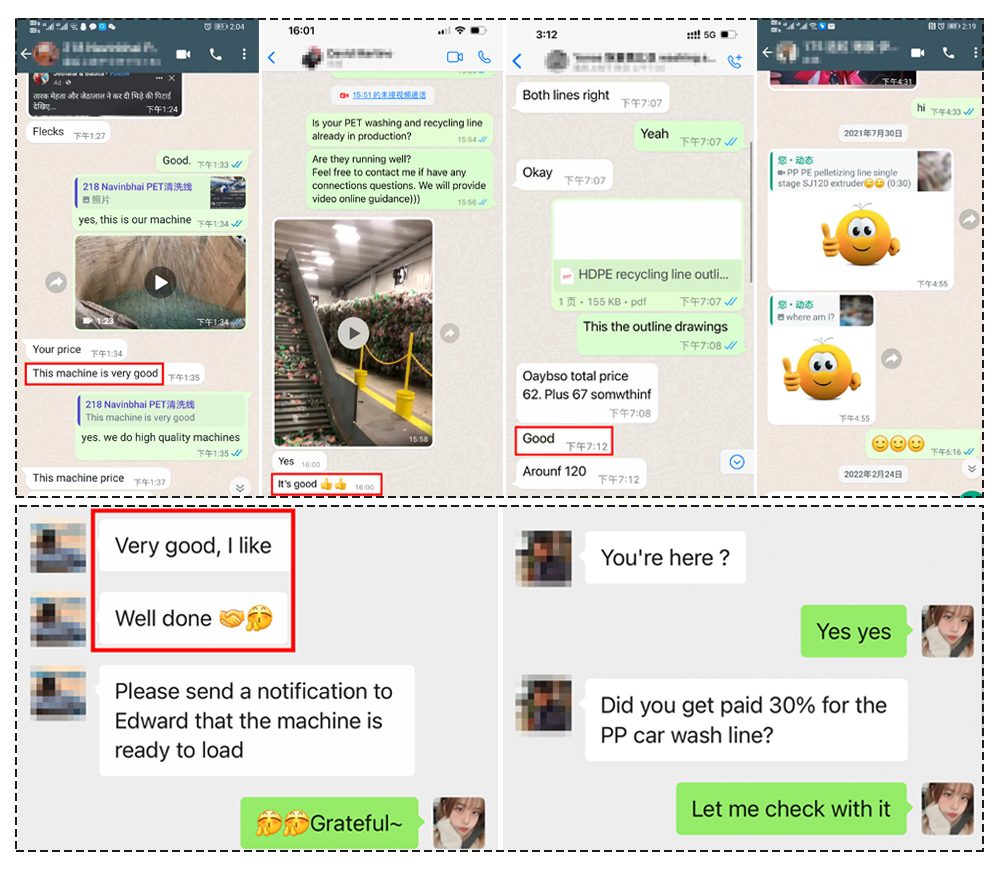

Service&Customer

1. We will provide testing if the customer comes to visit factory to see the machine.

2. We will provide detail machine technical specification ,electric diagram,installation,operation manual and all the documents

which customer needed for clearing customs and using the machine.

3. We will provide engineers for helping installation and training the workers at customer's site.

4.Spare parts are available when they are needed .Within warranty time,we we will provide spare parts free,and over warranty

time,we will provide spare parts with factory price.

5. We will provide technical support and repair service in the whole lifetime .

2. We will provide detail machine technical specification ,electric diagram,installation,operation manual and all the documents

which customer needed for clearing customs and using the machine.

3. We will provide engineers for helping installation and training the workers at customer's site.

4.Spare parts are available when they are needed .Within warranty time,we we will provide spare parts free,and over warranty

time,we will provide spare parts with factory price.

5. We will provide technical support and repair service in the whole lifetime .

Packaging&Delivery

Here’s a revised version of your FAQ in a more polished format:

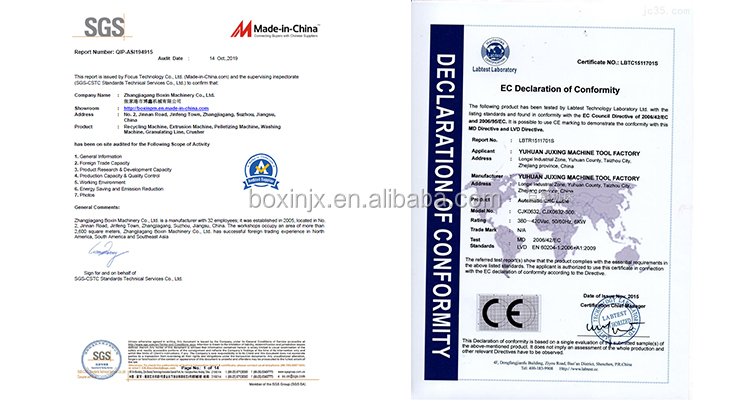

1) Are you a manufacturer or a trading company?

We are a manufacturer with 20 years of experience in the plastic recycling machinery industry.

2) What kind of machines do you produce?

We specialize in manufacturing plastic washing and recycling machines, as well as plastic granulation machines.

3) What payment terms do you accept?

We accept payments via T/T (Telegraphic Transfer) and L/C (Letter of Credit).

4) How long does it take to produce the machines?

Production time varies based on the machine model and configuration, typically ranging from 40 days to 2 months.

5) Will the machine be delivered on time?

Yes, we will ensure timely delivery once the balance payment is received.

6) How about the quality of your machines?

Our machines are of high quality. We strictly select each part used in production, and our professional workers handle all production and installation. We test each step to ensure the best performance.

7) How competitive is your price?

Our prices are competitive, considering the quality of the raw materials we use, including top-tier brands like Siemens, Schneider, and ABB. We aim to provide the best machines at the best price.

8) What is the warranty period for your machines?

Our machines come with a one-year warranty.

9) What after-sales services do you offer?

We provide comprehensive after-sales support, including sending engineers to your factory for installation and training, as well as 24-hour online customer service.

This version maintains the same information but in a more structured and professional tone. Let me know if you’d like any further adjustments!

Related Keywords

Related Keywords

You May Also Like

You May Also Like