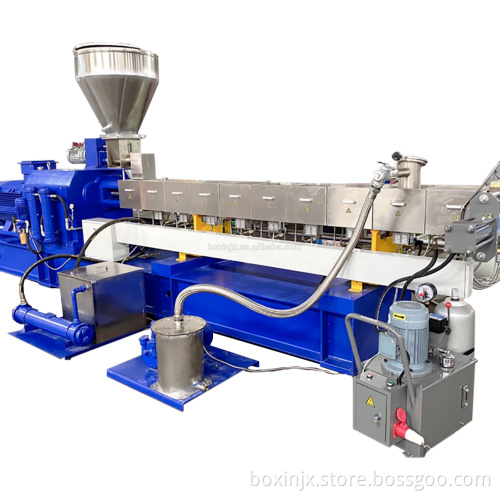

PET Flakes Single Stage Recycling Granulator Machine for High Output PET Granules Production

-

$200000.001-2 set

-

$70000.00≥3 set

- Min. Order:

- 1 set

- Min. Order:

- 1 set

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | L/C,Western Union,D/P,D/A,T/T,MoneyGram |

|---|

Application

Applicable materials for plastic pelletizer machine: PP,PE, LDPE, LLDPE, HDPE, BOPP, EPS,etc.

Material shape: Woven bags, pp pe film,printed LDPE film (rolls, loose, bundled), agriculture film, foamed plastics and raffia, etc.

Note: depending on material property, various downstream equipments are available.

Main Features

1) Single stage extruder and double stage extruders can be used according to user's requirement or material condition.

2) Plastic pelletized polyethylene (PE), polypropylene (PP), polystyrene (PS), polyvinyl chloride (pvc), PET, HDPE, ABS and other engineering plastics or general plastics recycling and granulation.

3) Granules cutting type: water ring face cutting, strip/noodle type cutting and hot cutting;

4) Waste woven bags and waste film can be directly put into the granulation line without crushing.

5) The main engine is equipped with full automatic control cabinet and PLC operating system. It is easy to operate and has stable performance.

6) Low energy consumption, remarkable energy saving effect, high output, mechatronics. Plastic granulation

Advantages

1) Suitalbe for plastic film PP ,PE ,HDPE,LDPE,LLDPE and so on.

2) Equipped with the vertical and horizontal force-feeding device to ensure high output.

3) Vent design on the barrel to evaporate the volatiles form the recyle material.

4) Hydraulic screen change unit and pressure gauge for easy operation and safety.

5) Water chamber with die face cutter simplifes the process.

6) The vertical centrifuge separates and dry the pellets faster.

7) High-efficient force-feeder ensures high capacity feeding, low energy consumption

8) Plastic pelletizer style: water-ring cutting with extrusion mould, even cutting ensures good shape.

SJ series plastic granulator

Technical parameters

SJ series single-stage pe pp film granulator machine(with side feeder)

| Model | SJ-65 | SJ-80 | SJ-100 | SJ-120 | SJ-150 | SJ-200 |

| Screw Dia. | 65 | 80 | 100 | 120 | 150 | 200 |

| L/D | 28-30 | 28-30 | 28-30 | 28-30 | 28-30 | 28-30 |

| Capacity | 60-80kg/h | 80-100kg/h | 150kg/h | 300kg/h | 500kg/h | 800kg/h |

SJ series double-stage pe pp film granulator machine(with side feeder)

| Model | SJ-100/100 | SJ-120/120 | SJ-150/150 | SJ-200/200 |

| Screw Dia. | 100 | 120 | 150 | 200 |

| L/D |

28-30 10-15 |

28-30 10-15 |

28-30 10-15 |

28-30 10-15 |

| Capacity | 120-180kg/h | 300kg/h | 400-500kg/h | 800-900kg/h |

Final products for your reference

Equipment selection, technical negotiation process:

1. Let you know machines' details technical specification and character.

2. Designing the machines and arrange the water, electric layout according to your requirement.

3. We can provide turnkey project according to your requirement.

Equipment production process:

1. Improve product quality through advanced production management.

2. Let you know production schedule through regular pictures, video, show the real production process to you.

3. Invite you or your third party, to our factory to test, inspection machine before shipment, until you are satisfied.

Equipment operation process:

1. Engineers are available to your factory for installation, commissioning, technical guidance and personnel training.

2. The equipment is completely free of charge for 12 months warranty. Spare parts are supplied with cost prices after 12moths after warranty time.

3. Establish the customer database, all the sold equipment can be checked any time.

4. Visit customers regularly, follow up the usage of each customer's equipment.

5. Increase service stations gradually, effectively improve service and spare parts supply speed.

Related Keywords