Daily Production of Ceramic Insulator 20 Tons

- Payment Type:

- L/C, T/T, D/P, Western Union

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Jiangsu Suzhou |

|---|---|

| Payment Type: | L/C, T/T, D/P, Western Union |

Product Description

Product Description

About us

Our areas of expertise cover technical project management, design translation, construction machinery, different area machine lines, mechanical and turnkey project solutions, considerable installations such as purchase solution and equipment examinations as well as turnkey project relating to installation in your country of clay brick plant, road machinery, construction machinery, industrial kiln and furnace, agricultural machinery etc.

For design, development, application, installation or simply consultation, Special Project Solutions can find solutions for your situation based on safety, budget and practicality from our company professional working team.

Brief introduction of process

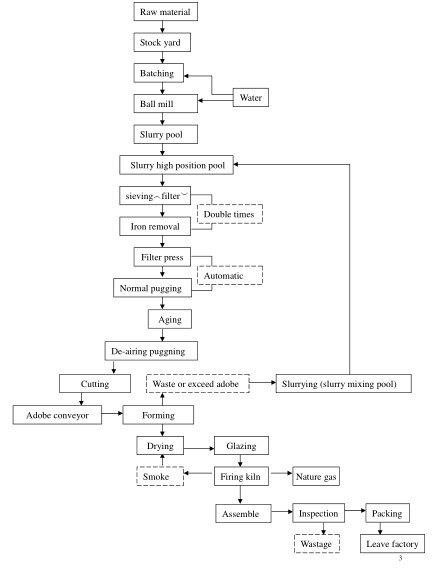

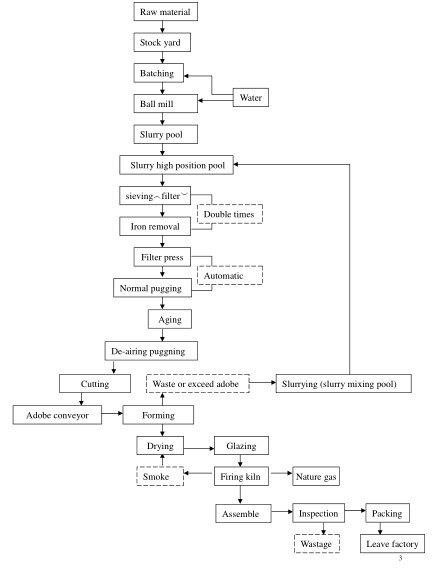

Raw material after batching, through ball mill milling, enter slurry pool mixing and enter a high position slurry for mixing with old slurry, the mixed slurry after double vibrating sieving and de-ironing, it enter filter press pressing, become clay plate, the clay plates automatic enter pug mill by auto clay plate conveying system for normal puggning than aging, after aging, the raw material enter to de-airing pug mill for de-airing puggning, its density and forming property is better. The extruded adobe will be cutting to fixed length and diameter then enter to belt conveyor, the forming machine are on both sides of belt conveyor, the worker take the extruded adobe for forming on the revolving machine, then and green insulator enter drying room drying, after drying is manual glazing and firing. At last is inspection and packing.

Flow Chart

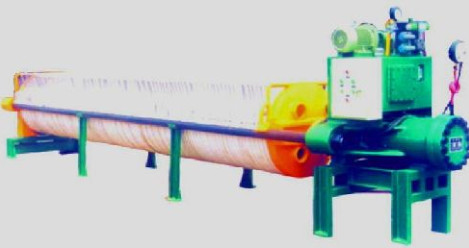

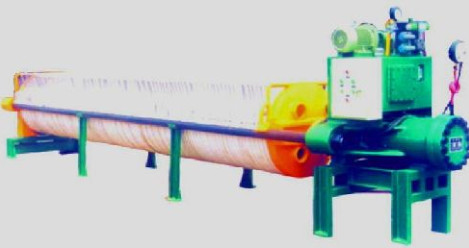

Filter press

Electrical surveying equipment

Our areas of expertise cover technical project management, design translation, construction machinery, different area machine lines, mechanical and turnkey project solutions, considerable installations such as purchase solution and equipment examinations as well as turnkey project relating to installation in your country of clay brick plant, road machinery, construction machinery, industrial kiln and furnace, agricultural machinery etc.

For design, development, application, installation or simply consultation, Special Project Solutions can find solutions for your situation based on safety, budget and practicality from our company professional working team.

Brief introduction of process

Raw material after batching, through ball mill milling, enter slurry pool mixing and enter a high position slurry for mixing with old slurry, the mixed slurry after double vibrating sieving and de-ironing, it enter filter press pressing, become clay plate, the clay plates automatic enter pug mill by auto clay plate conveying system for normal puggning than aging, after aging, the raw material enter to de-airing pug mill for de-airing puggning, its density and forming property is better. The extruded adobe will be cutting to fixed length and diameter then enter to belt conveyor, the forming machine are on both sides of belt conveyor, the worker take the extruded adobe for forming on the revolving machine, then and green insulator enter drying room drying, after drying is manual glazing and firing. At last is inspection and packing.

Flow Chart

Filter press

Electrical surveying equipment

| Equipments List | ||||

| SN | Name | Type | Unit | QTY |

| 1 | Ball mill | TCQ-8 | set | 3 |

| 2 | Ball mill | TCQ-1 | set | 1 |

| 3 | Ball mill | TCQ-0.5 | set | 1 |

| 4 | Screw Stirrers | TCJJ75 | set | 5 |

| 5 | Plunger pump | WDN140-B | set | 6 |

| 6 | Vibrating screen | WDS φ1200 | set | 2 |

| 7 | Vibrating screen | WDSφ500 | set | 2 |

| 8 | Magnetic separator | CT250 | set | 4 |

| 9 | Filter press | WD75K | set | 3 |

| 10 | Automatic clay plate conveyors | set | 1 | |

| 11 | Coarse pug mill | WDL300 | set | 1 |

| 12 | De-airing pug mill | WDL250 | set | 1 |

| 13 | De-airing pug mill | WDL350 | set | 1 |

| 14 | Vacuum pumps | X-25 | set | 2 |

| 15 | Automatic cutting machine |

WDZ-2A | set | 3 |

| 16 | Forming machine | WDX-3 | set | 10 |

| 17 | Manual glazing machines |

QD525 | set | 1 |

| 18 | Drying chamber | 3500 ×2500 | set | 10 |

| 19 | Shuttle kiln | 25m3 | set | 2 |

| 20 | Electrical surveying equipment |

WDY250 | set | 1 |

| 21 | Strength testing equipments |

200KN | set | 1 |

| 22 | Drying car | 1000 × 2000 |

set | 251 |

| 23 | Belt conveyor | B600 | set | |

Related Keywords

Related Keywords