1 Position PA6 Industrial Yarn Making Machine Line

- Payment Type:

- L/C, T/T, D/P, Western Union

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Jiangsu Suzhou |

|---|---|

| Payment Type: | L/C, T/T, D/P, Western Union |

Product Description

Product Description

We can design the production line according to your requirements. The following data is just for your reference.

1. Design Basis

Capacity: 400 ton/ year

(Based on 24hours/day)

Product: FDY

Denier (de): 840d

No. of holes: 36

Ends/pos.: 4

Position: 1

Sample(de/f): 840/36

Spinning speed (M/min): 2,500

Output (Ton/year): 400

The line needs 3 shifts per 24 hours, 3 workers and one worker maintain the production per shift.

2. Engineering Scope

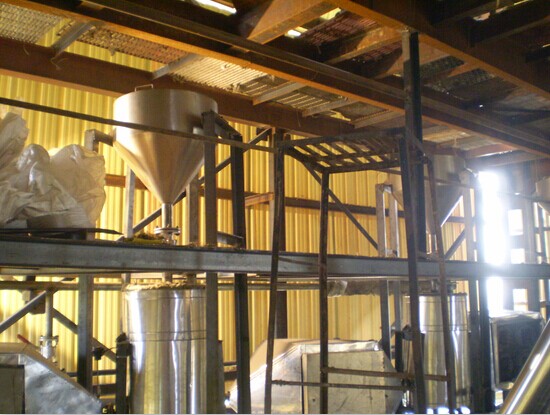

Part 1: PA6 Drying Equipment

Technical parameter

1. PA6 slice

Cylindrical φ2.5×2mm (If use other slice, please let the seller know it).

Slice density: 650kg/m3

Moisture content of wet slice: ≤500ppm

Moisture content of dry slice: ≤80 ppm (rated capacity)

2. Inlet air temperature of the drying system : 80-100ºC

3. Drying time: 20 – 24hours

4. Dry air dew point: ≤-70ºC(under the normal atmospheric pressure)

5. Consumption requirements of conveying and continuous drying device as follows:

Supply power: 380V/50HzAc

6. Compressed air requirements:

Air temperature: ≤35 ºC

Air pressure: ≥0.7 Mpa

Oil content of compressed air: ≤5 ppm

User gas source must meet the requirements of instrument air

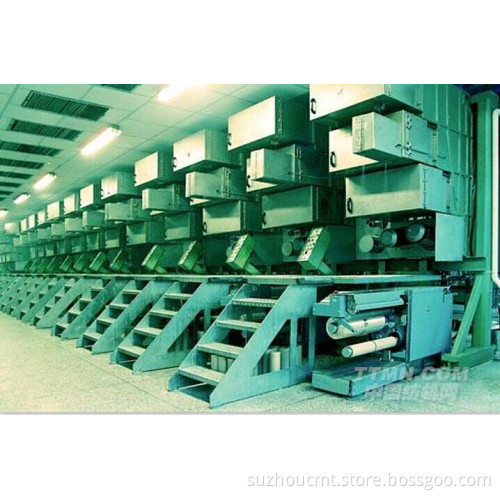

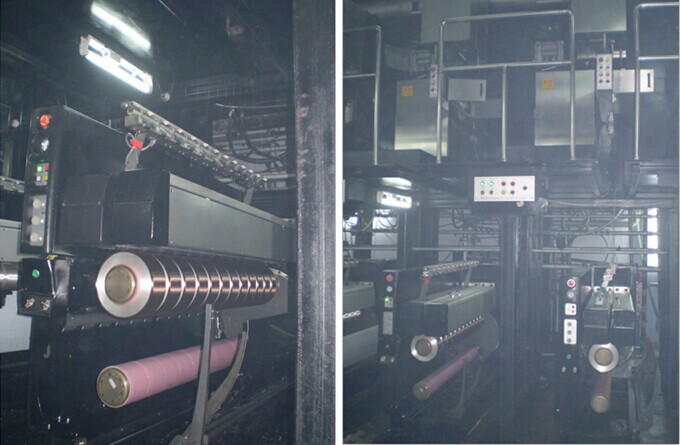

Part 2 PA6 industrial yarn production line

Flow Chart

Raw material --- Drying --- Screw melt extrusion --- Cooling --- Oiling on the silk flock ---- Multi-stage drawing --- Network nozzle --- Winding

Part 3 Testers

It will use for sampling inspection in daily production.

Equipment List:

(1) Electronic single yarn strength tester

(2) Skein Length Meter

Part 4 Auxiliary equipment

Equipment List:

(1) Air conditioning unit

(2) Screw air compressor set

(3) Oil mixing tank

(4) Vacuum oven

(5) Ultrasonic cleaning machine

(6) Heat preserving furnace

(7) Wire rack car

3. Finished Product

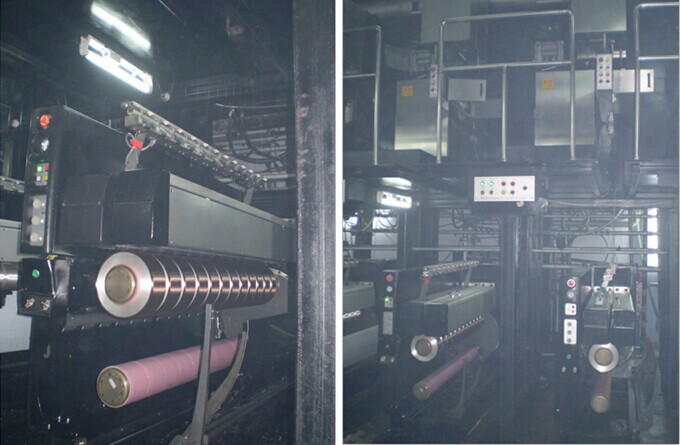

4. Parts of PA6 Industrial Yarn Factory Project

4. Parts of PA6 Industrial Yarn Factory Project

1. Design Basis

Capacity: 400 ton/ year

(Based on 24hours/day)

Product: FDY

Denier (de): 840d

No. of holes: 36

Ends/pos.: 4

Position: 1

Sample(de/f): 840/36

Spinning speed (M/min): 2,500

Output (Ton/year): 400

The line needs 3 shifts per 24 hours, 3 workers and one worker maintain the production per shift.

2. Engineering Scope

Part 1: PA6 Drying Equipment

Technical parameter

1. PA6 slice

Cylindrical φ2.5×2mm (If use other slice, please let the seller know it).

Slice density: 650kg/m3

Moisture content of wet slice: ≤500ppm

Moisture content of dry slice: ≤80 ppm (rated capacity)

2. Inlet air temperature of the drying system : 80-100ºC

3. Drying time: 20 – 24hours

4. Dry air dew point: ≤-70ºC(under the normal atmospheric pressure)

5. Consumption requirements of conveying and continuous drying device as follows:

Supply power: 380V/50HzAc

6. Compressed air requirements:

Air temperature: ≤35 ºC

Air pressure: ≥0.7 Mpa

Oil content of compressed air: ≤5 ppm

User gas source must meet the requirements of instrument air

Part 2 PA6 industrial yarn production line

Flow Chart

Raw material --- Drying --- Screw melt extrusion --- Cooling --- Oiling on the silk flock ---- Multi-stage drawing --- Network nozzle --- Winding

Part 3 Testers

It will use for sampling inspection in daily production.

Equipment List:

(1) Electronic single yarn strength tester

(2) Skein Length Meter

Part 4 Auxiliary equipment

Equipment List:

(1) Air conditioning unit

(2) Screw air compressor set

(3) Oil mixing tank

(4) Vacuum oven

(5) Ultrasonic cleaning machine

(6) Heat preserving furnace

(7) Wire rack car

3. Finished Product

| No. | Name | Capacity | QTY | Description | Remarks |

| 1 | PA6 drying equipment | 60kg/h | 1 set | Slice crystallizing, drying system | Where contact the material is made of the stainless steel. Outside surface is made of the carbon steel with the anticorrosive paint processing. |

| 2 | PA6 industrial yarn production line | 400 ton/year | 1 set | 840d | |

| 3 | Testers | 2 set | An electronic single yarn strength tester and a skein length meter. | ||

| 4 | Auxiliary equipment | 6sets |

Related Keywords

Related Keywords

You May Also Like

You May Also Like