PVB Film Making Machine Line

- Payment Type:

- L/C, T/T, D/P, Western Union

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Jiangsu Suzhou |

|---|---|

| Payment Type: | L/C, T/T, D/P, Western Union |

Product Description

Product Description

We can design the production line according to your requirements. The following data is just for your reference.

1. Brief Introduction

Capacity: 1,130 ton/year

Output capacity: 157kg/h

Finished effective width: 2,000mm Thickness: 0.38mm

Based on 24 hour/days, 3 shifts, 300 days/year.

It needs about 4 workers each shift,12 workers 3 shifts to finish the work.

2. Procedure:

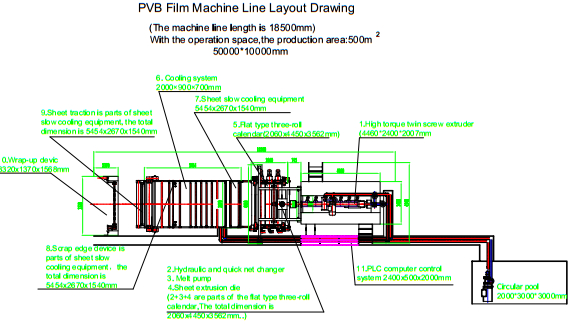

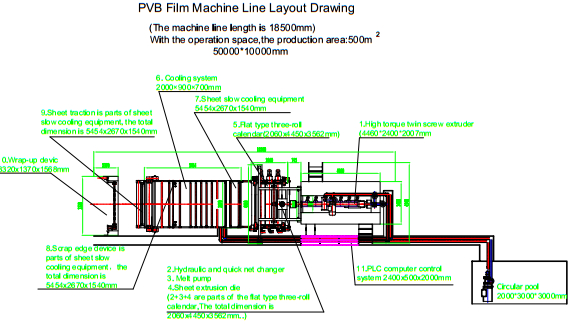

1.High torque twin screw extruder(use for extruder the plastic material)

2.Hydraulic and quick net changer (use for filter material content of impurities)

3. Melt Pump

4.Sheet extrusion die

5. Flat type three-roll calendar

6. Separate type roller temperature equipment

7. Sheet slow cooling equipment

8. Scrap edge device

9. Sheet traction part

10.Wrap-up device

11.PLC computer control (control all the machines)

3. Finished Product

4. Layout of factory

5. Machine List

Scrap edge device

1. Brief Introduction

Capacity: 1,130 ton/year

Output capacity: 157kg/h

Finished effective width: 2,000mm Thickness: 0.38mm

Based on 24 hour/days, 3 shifts, 300 days/year.

It needs about 4 workers each shift,12 workers 3 shifts to finish the work.

2. Procedure:

1.High torque twin screw extruder(use for extruder the plastic material)

2.Hydraulic and quick net changer (use for filter material content of impurities)

3. Melt Pump

4.Sheet extrusion die

5. Flat type three-roll calendar

6. Separate type roller temperature equipment

7. Sheet slow cooling equipment

8. Scrap edge device

9. Sheet traction part

10.Wrap-up device

11.PLC computer control (control all the machines)

3. Finished Product

4. Layout of factory

5. Machine List

Scrap edge device

Related Keywords

Related Keywords