Velcro Making Machine Line Proposal

- Payment Type:

- L/C, T/T, D/P, Western Union

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Jiangsu Suzhou |

|---|---|

| Payment Type: | L/C, T/T, D/P, Western Union |

Product Description

Product Description

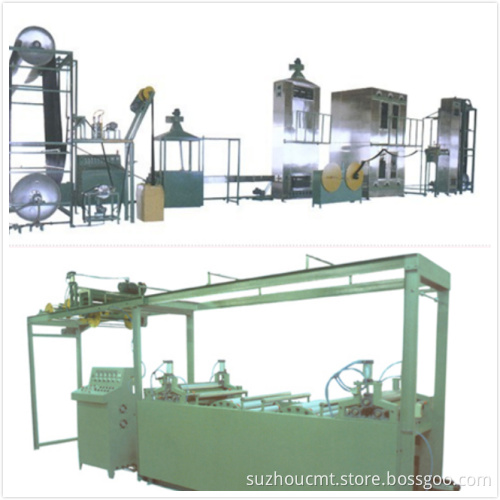

We can design the production line according to your requirements. The following data is just for your reference.

1. Brief Introduction

Velcro size: W*L=2.5cm*25m/roll

Capacity: 246 ton/year

Based on 24 hour/days, 300 days/year.

It needs about 15 workers each shift,

about 45 workers for three shifts to finish the work.

2. Procedure:

1. Make the yarn warp in the warp thread machine after winding the yarn on the warp thread machine

2. Weaving the Velcro

3. 2 ton fuel boiler heating the temperature

4. Fix the shape by the velcro gum setting machine

5. Napping the fabric by the napping machine

6. Break the hook by the Break hook machine

7. Cut the hook side and wool side by the strip cutter machine

8. Stick the strip and glue by the conveyor and then rolled up by the hot melting glue machine.

9. Package

3. Finished Product

4. Machine List

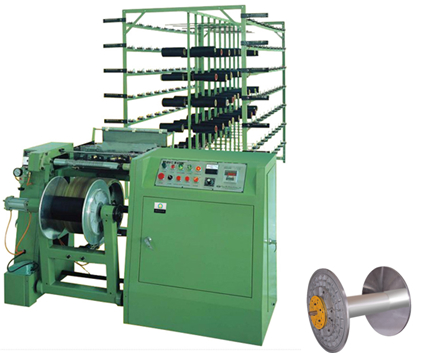

High-speed knitting machine

1. Brief Introduction

Velcro size: W*L=2.5cm*25m/roll

Capacity: 246 ton/year

Based on 24 hour/days, 300 days/year.

It needs about 15 workers each shift,

about 45 workers for three shifts to finish the work.

2. Procedure:

1. Make the yarn warp in the warp thread machine after winding the yarn on the warp thread machine

2. Weaving the Velcro

3. 2 ton fuel boiler heating the temperature

4. Fix the shape by the velcro gum setting machine

5. Napping the fabric by the napping machine

6. Break the hook by the Break hook machine

7. Cut the hook side and wool side by the strip cutter machine

8. Stick the strip and glue by the conveyor and then rolled up by the hot melting glue machine.

9. Package

3. Finished Product

4. Machine List

Warp thread machine

High-speed knitting machine

Related Keywords

Related Keywords