Tire Foam Making Machine Line Turnkey Project

- Payment Type:

- L/C, T/T, D/P, Western Union

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Jiangsu Suzhou |

|---|---|

| Payment Type: | L/C, T/T, D/P, Western Union |

Product Description

Product Description

We can design the production line according to your requirements. The following data is just for your reference.

1. Brief Introduction (It is only for your reference.)

Capacity: 83.31 ton/ year

Product weight: 200g/pc

Quantity/Year: 416,550pcs

Ingredient: tire wax 50%, water 30%, foam powder 10%, tackifier 10%.

2. Working time

8 hours/day, 300 days/year

3. Workers (It is only for your reference.)

Total workers: 2

1 worker for 200L prepare pot

1 worker for semi-automatic spray filling machine

4. Flow charts

4.1 Put tire wax 50%, water 30%, foam powder 10%, tackifier 10% into the 200L prepare pot and turn on the 200L prepare pot to stir them together.

4.2 Put bottles under semi-automatic filling machine, after filling then put the valve of bottle into the bottle, and then put bottle under the semi-auto sealing machine, after sealing then put the bottle under the semi-automatic filling gas machine to fill gas, at last put on the bottle cap.

4.3 Put the finished products into the cartoons.

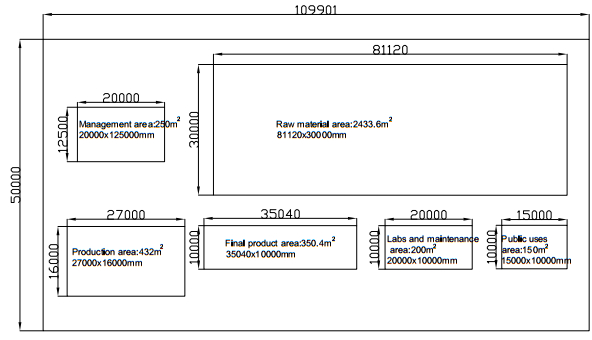

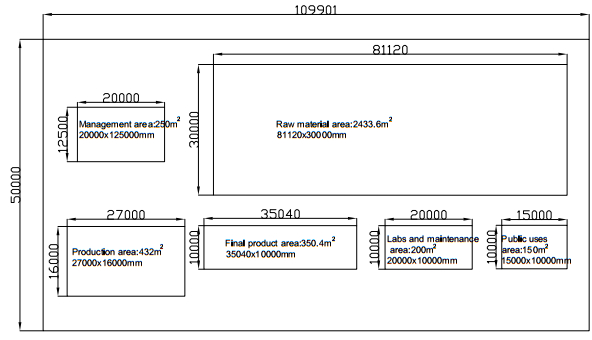

5. Layout of the factory

6. Finished Product

7. Machine list

7. Machine list

1. Brief Introduction (It is only for your reference.)

Capacity: 83.31 ton/ year

Product weight: 200g/pc

Quantity/Year: 416,550pcs

Ingredient: tire wax 50%, water 30%, foam powder 10%, tackifier 10%.

2. Working time

8 hours/day, 300 days/year

3. Workers (It is only for your reference.)

Total workers: 2

1 worker for 200L prepare pot

1 worker for semi-automatic spray filling machine

4. Flow charts

4.1 Put tire wax 50%, water 30%, foam powder 10%, tackifier 10% into the 200L prepare pot and turn on the 200L prepare pot to stir them together.

4.2 Put bottles under semi-automatic filling machine, after filling then put the valve of bottle into the bottle, and then put bottle under the semi-auto sealing machine, after sealing then put the bottle under the semi-automatic filling gas machine to fill gas, at last put on the bottle cap.

4.3 Put the finished products into the cartoons.

5. Layout of the factory

6. Finished Product

7. Machine list

7. Machine listRelated Keywords

Related Keywords

You May Also Like

You May Also Like