Fruit Juice & Carbonated Beverage Production Line (Turnkey Project)

- Payment Type:

- L/C, T/T, D/P, Western Union

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Jiangsu Suzhou |

|---|---|

| Payment Type: | L/C, T/T, D/P, Western Union |

Product Description

Product Description

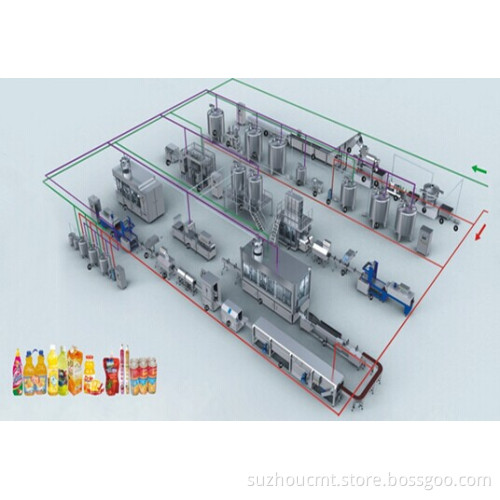

Carbonated beverages and HOT FILLED JUICES

Include : Sugar dissolving, filtering and storage, product mixing and storage, Processing, rinsing/filling/capping, warming/cooling, date coding, PVC sleeve bottle labeling and cap tax sleeve labeling, shrink wrapping and PET bottle feeding air conveyor by manual.

1. 6,000 BPH juice production line in 250ml. PET bottles. Tubular sterilizer will sterilize drink at 95 degrees Centigrade with holding time of 30 seconds and cool down to 55 degrees Centigrade for filling.

2.12,000 BHP CSD beverage production line in the same 250ml. PET bottles. The CSD CO2 intermix must be capable to produce CO2 volume of 4.0 %.

3. One common water treatment plant is of 8,000 liters per hour capacity which will supply water to both the lines (juice and CSD) for sugar dissolving and mixing and in to a common manual CIP system. Sand filter, active carbon filter, polishing cartridge filters of 5 micron and then 0.5 micron and then storage in 5,000 x 2 storage tanks.

We provide customized service. Details above are only for your reference.

Include : Sugar dissolving, filtering and storage, product mixing and storage, Processing, rinsing/filling/capping, warming/cooling, date coding, PVC sleeve bottle labeling and cap tax sleeve labeling, shrink wrapping and PET bottle feeding air conveyor by manual.

1. 6,000 BPH juice production line in 250ml. PET bottles. Tubular sterilizer will sterilize drink at 95 degrees Centigrade with holding time of 30 seconds and cool down to 55 degrees Centigrade for filling.

2.12,000 BHP CSD beverage production line in the same 250ml. PET bottles. The CSD CO2 intermix must be capable to produce CO2 volume of 4.0 %.

3. One common water treatment plant is of 8,000 liters per hour capacity which will supply water to both the lines (juice and CSD) for sugar dissolving and mixing and in to a common manual CIP system. Sand filter, active carbon filter, polishing cartridge filters of 5 micron and then 0.5 micron and then storage in 5,000 x 2 storage tanks.

We provide customized service. Details above are only for your reference.

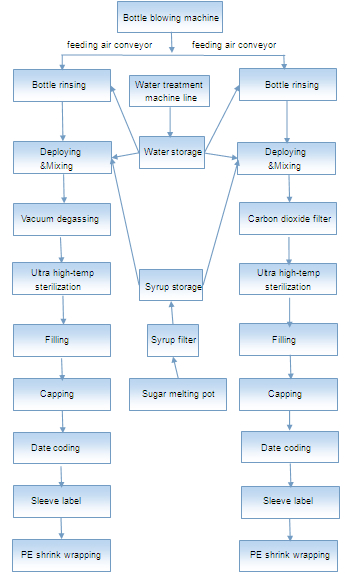

Flow Chart

| Rated capacity | 12000BPH, 6000BPH (250ml standard thread bottle) |

| Filling volume | 250ml standard bottle |

| Filling material | Fruit juice drinks, carbonated drinks |

| Volume size | PET bottle, applicable to the bottle diameter Phi 50 mm to 170mm |

| Bottle height | 150 ~ 320mm, special requirements can be customized |

| Filling method | Constant pressure, normal pressure filling |

| Capping form | Plastic screw cap |

| Filling accuracy | + 3mm (level) |

| Air pressure | 0.5 ~ 0.6Mpa |

| Gas consumption | 1.5m3/min |

Related Keywords

Related Keywords