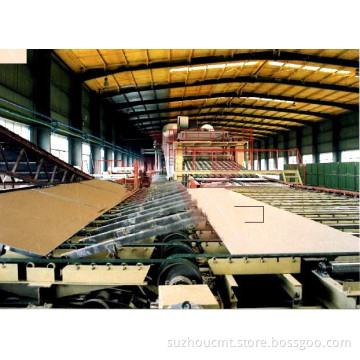

Concrete Mix Plant for Building Materials

- Payment Type:

- L/C, T/T, D/P, Western Union

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Jiangsu, Suzhou |

|---|---|

| Payment Type: | L/C, T/T, D/P, Western Union |

Product Description

Product Description

I. Process flow

1. To start the homogeneous batching process of raw materials by sequence according to their distance from the mixer;

2. Each material evenly goes into the mixer in proportion;

3. Mixer mixes material, at the same time pushes head. When it comes out, become finished product;

4. To stop the homogeneous batching process of raw materials by sequence according to their distance from the mixer.

II. Main Technical Parameters

III. Engineering vehicle

1. Concrete Mixer Truck

Brief Introduction

The product is mainly used for mixing and transporting concrete mixture between long distances. It can effectively delay pre-hardening, avoid stratification and eduction, and ensure construction quality and speed. The series of truck-mounted concrete mixers can be divided into various models, such as 8m³, 9m³, 10m³, 12m³, 14m³ and 16m3, which can be matched with any special domestic and foreign chassis according to customers' choices. The driving system of the mixing drum adopts the closed-type hydraulic system pump, motor and reducer which are imported from the US and Germany with original packaging. The necessary hydraulic accessories such as the oil tank, radiator, filter and rubber hose connector are all imported parts. All this ensures the hydraulic system a long service life. The mixing drum body and the double-logarithmic variation-parameter helical vanes are all made of fine-grain abrasion-resistant steel plates specially used for the B520JJ mixing drum made by Shanghai Baosteel Company. All the quick-wearing parts like the feed hopper and discharge hopper chutes which have much contact with concrete are also armored with abrasion-resistant steel plates, which correspondingly ensure the product a rather long service life. Not only are many mixing arms designed in the mixing drum, but also square and round holes are scientifically arranged in the mixing vanes. This design has realized the actual three-dimensional mixing of concrete in the mixing drum, with discharge surplus close to zero and eduction concrete greatly avoided. The moveable discharge chute can be locked at 4 different positions for discharge operations in different directions. The upper part of the truck adopts the shot blasting and baking finish technology. While elegant and pleasing in design, the truck-mounted mixer shows many advantages such as stable and reliable slewing, speedy discharge, low surplus rate, handy operation and long service life.

2. Concrete Pump Truck

The Truck-mounted Concrete Pump with Distributing Boom (or Pump Truck for short) is developed by CMT Group on the basis of drawing on advanced domestic and foreign experience and using advanced modern computer simulation techniques to systematically analyze the effect of changes in various parameters like stress, displacement and natural frequency on the boom's fatigue life. Meantime, CMT Group optimized the design of the hydraulic system, adopted the latest free fluid technique and greatly lessened the impact of pumping commutation on the distributing boom. In the boom structure optimization and the hydraulic system design, CMT Group has obtained many patents. The consummate control of product quality, perfect techniques of product manufacturing and strict procedures of quality inspection make the CMT Pump Truck a leading product in China and an advanced product in the world. All the steel plates for the boom system are high-strength cold rolling steel plates made by the Swedish company SSAB. The yield strength of the plates exceeds 900Mpa, which ensures that the boom system has high strength and light weight. The boom system's distributing pipe, landing legs, oil tank and so on, have all received 100% stress-removing treatment after welding. Every welding seam has passed the 100% undamage and crack detection or X-ray radial check to avoid any tiny defects and to make the machine more enduring.

1. To start the homogeneous batching process of raw materials by sequence according to their distance from the mixer;

2. Each material evenly goes into the mixer in proportion;

3. Mixer mixes material, at the same time pushes head. When it comes out, become finished product;

4. To stop the homogeneous batching process of raw materials by sequence according to their distance from the mixer.

II. Main Technical Parameters

| Model | CMT180 | |

| Theoretical Productivity | 150-180m3/h | |

| Mixer | JS3000 | |

| Max Aggregate Diameter | 80mm | |

| Aggregate Bin Capacity | 4×25m3 | |

| Aggregate Conveying Mode | Flat Belt Conveyor | |

| Measuring Scope & Precision |

Aggregate | 7500Kg ±2% |

| Cement | 1800Kg ±1% | |

| Fly Ash | 900Kg ±1% | |

| Water | 900Kg ±1% | |

| Additive | 90Kg ±1% | |

| Power Supply | 3-phase, 380V/50HZ | |

| Mixing Power | 2*55kw | |

| Total Power | 220kw (excluding optional parts) | |

| Total Weight | 68T (excluding optional parts) | |

| Outline Dimension (in service: L×W×H) | 58.5m×7m×12.9m | |

| Discharging Height | 3.8 m | |

| Silos (optional) | At customers' requests | |

| Screw Conveyors (optional) | Each silo needs one φ273 or φ323 screw conveyor. | |

III. Engineering vehicle

1. Concrete Mixer Truck

Brief Introduction

The product is mainly used for mixing and transporting concrete mixture between long distances. It can effectively delay pre-hardening, avoid stratification and eduction, and ensure construction quality and speed. The series of truck-mounted concrete mixers can be divided into various models, such as 8m³, 9m³, 10m³, 12m³, 14m³ and 16m3, which can be matched with any special domestic and foreign chassis according to customers' choices. The driving system of the mixing drum adopts the closed-type hydraulic system pump, motor and reducer which are imported from the US and Germany with original packaging. The necessary hydraulic accessories such as the oil tank, radiator, filter and rubber hose connector are all imported parts. All this ensures the hydraulic system a long service life. The mixing drum body and the double-logarithmic variation-parameter helical vanes are all made of fine-grain abrasion-resistant steel plates specially used for the B520JJ mixing drum made by Shanghai Baosteel Company. All the quick-wearing parts like the feed hopper and discharge hopper chutes which have much contact with concrete are also armored with abrasion-resistant steel plates, which correspondingly ensure the product a rather long service life. Not only are many mixing arms designed in the mixing drum, but also square and round holes are scientifically arranged in the mixing vanes. This design has realized the actual three-dimensional mixing of concrete in the mixing drum, with discharge surplus close to zero and eduction concrete greatly avoided. The moveable discharge chute can be locked at 4 different positions for discharge operations in different directions. The upper part of the truck adopts the shot blasting and baking finish technology. While elegant and pleasing in design, the truck-mounted mixer shows many advantages such as stable and reliable slewing, speedy discharge, low surplus rate, handy operation and long service life.

2. Concrete Pump Truck

The Truck-mounted Concrete Pump with Distributing Boom (or Pump Truck for short) is developed by CMT Group on the basis of drawing on advanced domestic and foreign experience and using advanced modern computer simulation techniques to systematically analyze the effect of changes in various parameters like stress, displacement and natural frequency on the boom's fatigue life. Meantime, CMT Group optimized the design of the hydraulic system, adopted the latest free fluid technique and greatly lessened the impact of pumping commutation on the distributing boom. In the boom structure optimization and the hydraulic system design, CMT Group has obtained many patents. The consummate control of product quality, perfect techniques of product manufacturing and strict procedures of quality inspection make the CMT Pump Truck a leading product in China and an advanced product in the world. All the steel plates for the boom system are high-strength cold rolling steel plates made by the Swedish company SSAB. The yield strength of the plates exceeds 900Mpa, which ensures that the boom system has high strength and light weight. The boom system's distributing pipe, landing legs, oil tank and so on, have all received 100% stress-removing treatment after welding. Every welding seam has passed the 100% undamage and crack detection or X-ray radial check to avoid any tiny defects and to make the machine more enduring.

Related Keywords

Related Keywords

You May Also Like

You May Also Like