5MW Biomass Gasifier Power Plant

- Payment Type:

- L/C, T/T, D/P, Western Union

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Jiangsu Suzhou |

|---|---|

| Payment Type: | L/C, T/T, D/P, Western Union |

Product Description

Product Description

We can design the production line according to your requirements. The following data is just for your refernence.

1. Brief introduction

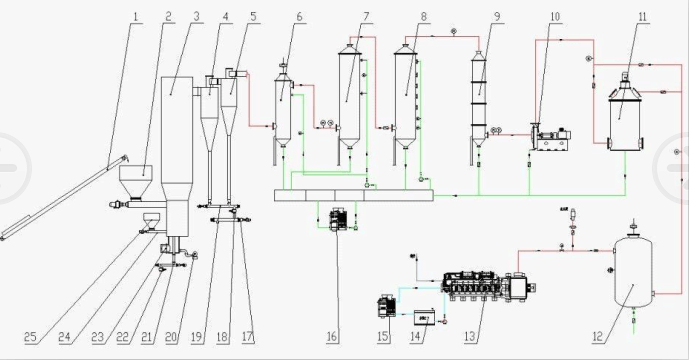

Comprehensively consider the characteristic of biomass gasification process and biomass to design 15MW biomass gasification power plants,we will adopt 3 sets of 5MW biomass gasification power plants in parallel. Biomass is constantly sent by feeding system to gasifier and react with a certain amount of air to produce fuel gas. After the hot gas is cleaned and cooled down by cleaning system, it is piped to internal combustion gen-set to output demanded power. To reasonable design the height and diameter of gasifier make sure good gasification condition and long residence time of biomass in gasifier in order to get high efficiency. The main technical process is shown by F1.

2. Main Technical Process

2.1 Preparation of Biomass

The humidity of biomass should be treated to 15% size should be lower than 4cm. After that, satisfied biomass is sent into biomass storage room. And at least, it is necessary to store adequate biomass which is enough to support plant to run fro one week.

2.2 Biomass Gasification Process

Biomass is fed continuously into gasifier by feeder located on the bottom of gasifier. Under the effect of hot bed material, biomass contact with air from the bottom of gasifier. At the same time, pyrolysis and gasification reaction happen so that biomass is converted into fuel gas. The main composition of fuel gas is CO, H2, CH4, etc. And some tar and dust are included in fuel gas. The heat value of fuel gas is 1000~1200kcal/Nm3.

2.3 Gas Purification Process

In the role of the airflow inside furnace, the biomass ash is carried out of the furnace, separated by the two-stage cyclone, the ash trapped is discharged by the ash discharge device.

2.4 Gas Cooling and Cleaning

Use water as media of purification process. Based on different temperature and ash content in different stage, choose to use different wet purification device with different capability in order to well remove tar and dust till gas quality meet the demand of IC Gen-set.

2.5 Power Generation Process

Cooled and cleaned gas is piped to cyclinder and mix with air to combust to produce electricity.

F1. Schematic diagram of fluidized bed gasification system for one set

3.Technical Features

3.1 High Gasification Efficiency

3.2 Fluid Ignition

3.3 Stable Running

3.4 High Automatic Level

4.Work Condition of fluidized bed gasification system

4.1 Altitude: <2000m surrounding

4.2 Temperature: -20ºC—40ºC

4.3 System is not suit

1. Brief introduction

Comprehensively consider the characteristic of biomass gasification process and biomass to design 15MW biomass gasification power plants,we will adopt 3 sets of 5MW biomass gasification power plants in parallel. Biomass is constantly sent by feeding system to gasifier and react with a certain amount of air to produce fuel gas. After the hot gas is cleaned and cooled down by cleaning system, it is piped to internal combustion gen-set to output demanded power. To reasonable design the height and diameter of gasifier make sure good gasification condition and long residence time of biomass in gasifier in order to get high efficiency. The main technical process is shown by F1.

2. Main Technical Process

2.1 Preparation of Biomass

The humidity of biomass should be treated to 15% size should be lower than 4cm. After that, satisfied biomass is sent into biomass storage room. And at least, it is necessary to store adequate biomass which is enough to support plant to run fro one week.

2.2 Biomass Gasification Process

Biomass is fed continuously into gasifier by feeder located on the bottom of gasifier. Under the effect of hot bed material, biomass contact with air from the bottom of gasifier. At the same time, pyrolysis and gasification reaction happen so that biomass is converted into fuel gas. The main composition of fuel gas is CO, H2, CH4, etc. And some tar and dust are included in fuel gas. The heat value of fuel gas is 1000~1200kcal/Nm3.

2.3 Gas Purification Process

In the role of the airflow inside furnace, the biomass ash is carried out of the furnace, separated by the two-stage cyclone, the ash trapped is discharged by the ash discharge device.

2.4 Gas Cooling and Cleaning

Use water as media of purification process. Based on different temperature and ash content in different stage, choose to use different wet purification device with different capability in order to well remove tar and dust till gas quality meet the demand of IC Gen-set.

2.5 Power Generation Process

Cooled and cleaned gas is piped to cyclinder and mix with air to combust to produce electricity.

F1. Schematic diagram of fluidized bed gasification system for one set

| No. | Process | No. | Process |

| 1 | Belt Conveyor | 2 | Biomass Silo |

| 3 | Gasifier | 4 | First step cyclone |

| 5 | Second step cyclone | 6 | First step spray tower |

| 7 | Second step spray tower | 8 | Turbulence tower |

| 9 | Purifying tower | 10 | Gas booster fan |

| 11 | Dry filter | 12 | Surge tank |

| 13 | Internal combustion engine and generator | 14 | Water pool |

| 15 | Cooling tower | 16 | Cooling tower |

| 17 | Humidifying screw conveyor | 18 | Star discharger |

| 19 | Charcoal discharging screw | 20 | Air blower |

| 21 | Bottom charcoal release screw | 22 | Star discharger |

| 23 | Balancing chamber | 24 | Sand feeding screw |

| 25 | Sand Silo |

3.Technical Features

3.1 High Gasification Efficiency

3.2 Fluid Ignition

3.3 Stable Running

3.4 High Automatic Level

4.Work Condition of fluidized bed gasification system

4.1 Altitude: <2000m surrounding

4.2 Temperature: -20ºC—40ºC

4.3 System is not suit

Related Keywords

Related Keywords